Hydrocarbon based industrial solvent cleaners for the safe removal of dirt, oil, grease and other contaminants

solvent cleaners are used in many industries to remove dirt, oil, grease, or other contaminants from metal surfaces without causing harm or leaving residue.

Cleaning solvents are used in many industries to remove dirt, oil, grease, or other contaminants from machined and fabricated metal, plastic and composite surfaces.

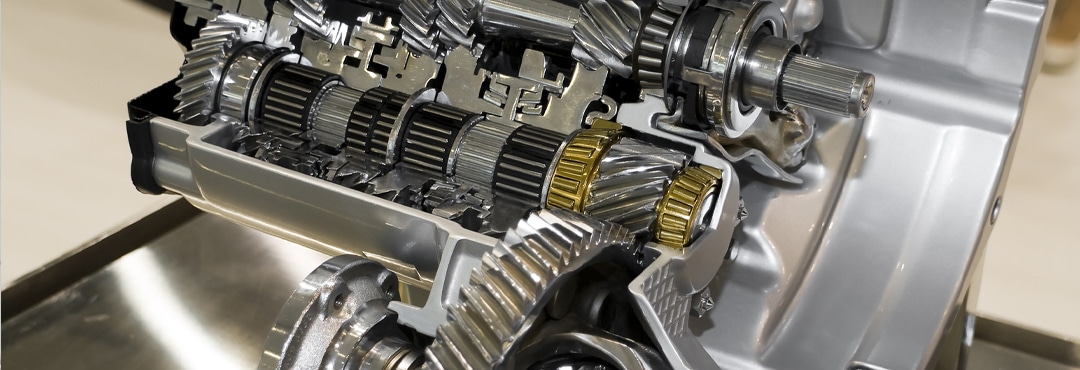

They are used as parts washers in manufacturing or automotive industries or are used as wipe cleaners for large surface areas prior to painting or powder coating.

A growing concern regarding environmental and health hazards of the most commonly used chlorinated solvents as industrial degreasing agents has led to this formulation of safer cleaning solvents.

Industrial solvent cleaning that is safe for users and the environment

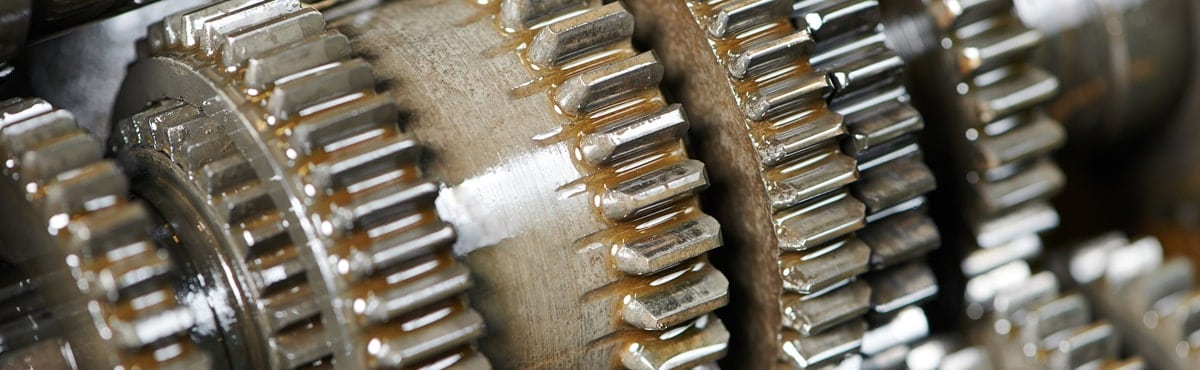

Solvents used for cleaning must be highly refined and leave no residues on drying. They have to be very effective in removal of oils and soils without causing damage or corrosion of the parts or components being cleaned and leave minimal residues which will be the result of process design.

Cleaning to remove process oils and particles can use single or multitank spray washers or immersion tanks with ultrasonics or agitation depending on the volume of components and cleaning specifications. These vary widely from very demanding automotive and aerospace applications to less demanding applications where critical cleaning is not a requirement.

What to consider when choosing suitable solvent cleaning products

Pre-used parts or assemblies from the transportation, aerospace or manufacturing equipment sectors are often very heavily contaminated when removed from service but must be free of these oils, soils, grease, dirt and contaminants before handling to disassemble prior to refurbishing and rebuilding. Much of this work will be manual and the considerations for the safety of operators, hand wiping or brush cleaning is paramount. Provision of personal protection equipment (PPE) such as gloves, overalls, safety glasses and possibly masks must be carefully considered to be sure the PPEs are compatible with the solvents.

Among other considerations are the working space where the cleaning applications are to be carried out. Flammability versus drying time is always an issue. It is preferable to use a slower drying high flash point solvent in enclosed areas. Good ventilation with a high extraction rate of air will assist drying. In enclosed machines with automatic handling a positive extraction rate of air and heated and extracted final tank can lower process times.

Flame proofing requirements and the insurance implications of the faster drying times of more volatile flammable solvents is often mitigated by the use of less volatile, lower VOC materials by design of machines and careful consideration of costs which these solvents offer in lower usage and longer tank life with much lower disposal costs of used materials.

Industrial solvent cleaning solutions:

Clarea® products are aliphatic hydrocarbon based low odour degreasing solvents with a specified flash points. They will remove oils, greases, hydraulic fluids cutting fluids and a wide variety of hydrocarbon based protective coatings.

Clarea® HC40 is a degreasing solvent with a flash point of 40°C. It will remove oils, greases, hydraulic fluids cutting fluids and a wide variety of hydrocarbon based protective coatings. Read more.

Clarea® HC62 is a degreasing solvent with a flash point over 60C. It will remove oils, greases, hydraulic fluids cutting fluids and a wide variety of hydrocarbon based protective coatings. It is suitable in ultrasonic systems and can be used as dip, brush or in hand-wipe process. Read more.

Product Benefits

EFFICIENT AND ECONOMICAL

- Versatile and cost effective solutions for all your industrial cleaning

- Low odour and low toxicity

- Multipurpose use can reduce the inventory of cleaning fluids required

- Clarea HC40 for brush and hand wiping, air dries. Flash point 40C

- Low evaporation, flammable and non-flammable products

- Non chlorinated

- Can be used as dip, brush or in hand-wipe process

- Relatively fast evaporation rate and are most suited to hand wipe and small immersion tanks

RELIABLE

- Safe, reliable, environmentally friendly cleaning

- Excellent customer service, technical support and training from qualified distributors throughout Europe