Latest Articles

Corrosion protection for electrical control systems in Wastewater Treatment Plants

SuperCORR A protects electrical control systems against corrosive environments

Wastewater treatment plants are subject to corrosion and rust from a variety of causes, one of which is Hydrogen Sulphide gas, (H2S). Corrosion is an insidious and costly problem that causes just about every metal and metal alloy to fail over time. Metals in electrical and electronic control systems, components, connectors, and switches are of most concern.

Corrosion is found in almost all process industries including wastewater treatment plants, pulp and paper mills, fertilizer plants, and numerous other industries and is not going away. Establishing a ‘Preventative Maintenance Program’ that includes corrosion prevention makes it a problem that can be cost effectively dealt with.

One proven and positive way to reduce, if not prevent, corrosion altogether from causing electrical, electronic systems and component failures is by using an ultra-thin film water displacing lubricant material with corrosion inhibiting compound, SuperCORR A has all these properties.

A proprietary formulation packaged in aerosol cans it uses a non-flammable fast drying carrier solvent. The aerosol is supplied with a flexible tube applicator which allows the protective coating to be applied accurately even in difficult to get to components.

Removal of surface contamination from the metallic contact surfaces on switches and circuit breakers is essential to ensure fault free operation. The aerosol uses the unique

SuperCORR A formulation to lift and remove dust and soils from the metal contact surfaces. An inert compound that neither reduces nor increases the electrical conductivity. SuperCORR A also provides long term protection from corrosion and electrical arcing that can lead to shorts and subsequent circuit failures.

Testing SuperCORR A in corrosive environments

SuperCORR A (MIL-DTL-87177B (Revised MIL-L-87177A) Type 1 Grade B lubricant was subjected to extensive and vigorous Mixed Flowing Gas (MFG) testing at Battelle Laboratories under a U.S. Government contract.

Specifications ASTM B827 and ASTM B845 Class III MFG testing protocol were used. This included gases with high corrosion potentials including Hydrogen Sulphide (H2S), Nitrous Oxide(NO2), and Chlorine (Cl2).

ASTM B845 refers to techniques for mixed flowing gas (MFG) tests containing gases that are applied to evaluate devices containing electrical contacts such as slip rings, separable connectors, electromechanical relays or switch contacts. The MFG tests accelerate corrosive degradation processes. Connectors and contacts within closed electronic cabinets may be affected by an environment of different severity than the outside of these cabinets. ASTM B827 outlines procedures for conducting environmental tests involving exposures to controlled quantities of corrosive gas mixtures. Equipment and methods for gas, temperature, and humidity control for tests to be conducted in a reproducible manner are described.

Reproducibility is measured using control coupons whose corrosion films are evaluated by mass gain, coulometry, or by various electron and X-ray beam analysis techniques. Reproducibility can also be measured by in situ corrosion rate monitors using electrical resistance or mass/frequency change methods. Full copies of these tests can be made available on request.

Industrial applications

SuperCORR A has a proven performance record in protecting electrical components, systems, connectors and electronics. The coating will also prevent the ingress of moisture and other contaminants onto the connector surfaces. These initiate corrosions and cause intermittent component failure or a premature degradation of component performance.

The Battelle Laboratories studies provided data and related processing information validating the benefits of using SuperCORR A. to protect the electrical connectors of line replacement units (LRUs) used in military aircraft avionic applications.

The results of the laboratory and field-testing activities conducted in these studies confirm that SuperCORR A is an extremely effective coating to protect electronics, electrical components and systems including switches and connectors with no compromise of the integrity of the electrical component/system even in very corrosive environments.

As a result of testing on site at a number of private and public companies with the confirmatory work at Battelle Laboratories SuperCORR A is being used to reduce maintenance and repair costs in a range of different industrial applications – wastewater treatment plants, pulp and paper mills, automotive and heavy equipment industries and in the power production sector oil and gas and renewable energy and in both the aviation and maritime industries.

FURTHER INFORMATION

Please visit our website www.envirotech-europe.com/supercorr-a for information about other uses and applications. For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Critical cleaning of electronics and electrical components

ProSolv® 5408 new sustainable solvent for critical cleaning of electronics and electrical components

Solvents are used throughout industries where extremely high performance and safety critical cleaning levels are required including aerospace, military and defence, electronics, semiconductor manufacturing, optics, and industrial machining.

ProSolv 5408e is an innovative contemporary highly effective, versatile defluxer developed to not only remove rosin flux, no-clean flux, oil, grease and wax contaminants, but also to eliminate residual halide salts, ions and other polar and non-polar soils and contaminants that often cause component failures with tracking and other issues impacting performance.

Solvents based on conventional chlorinated hydrocarbons have delivered the high standards required for critical cleaning in the past. These chemicals had desirable properties which when combined gave a profile which was perfect for vapour/vapour liquid degreasing when combined with suitable equipment as industrial cleaning systems.

Non-flammable, consistent azeotropes, low viscosity, high liquid density, very low surface tension, and effective wetting enabling them to penetrate tight spaces for optimum cleaning performance. High KB values allows for cleaning a variety of light and heavy soils including particulates, ionic soils, oils, waxes, and greases these are no longer acceptable.

Evolving legislation for ecodevelopment demanded by governments worldwide demand inventive and original formulations for the use of solvents to continue to comply with the increasingly stringent legislation for protection of the environment and, even more importantly, safety of operators who maybe exposed to the products. In applications where formulated blends of halogenated solvents have been used very effectively in the past these are now required by changes in legislation to be phased out of use.

With their 25 years wealth of experience in this field as the inventors of the highly regarded n propyl bromide (nPB) based EnSolv range of precision cleaning solvents EnviroTech Europe created a contemporary new formulation based on recent research and developed a new solvent as a replacement for the “old” technology which has been found to perform just as effectively, but without the negative environmental, health and safety issues.

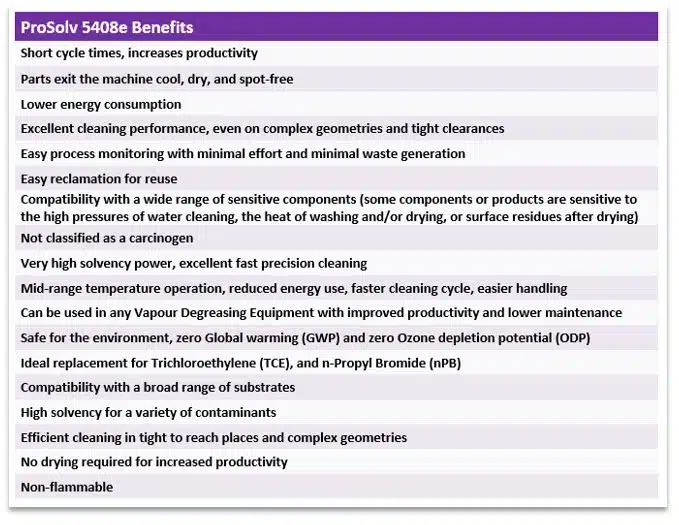

Listed above are just some of the benefits from using ProSolv 5408e, your forever sustainable solvent for cleaning and defluxing in the electronics and electrical components industry and an economical and efficient “drop in “for vapour / vapour liquid cleaning systems using legacy solvents. EnviroTech experts with many years of experience are available to guide you through changeover procedures or to advise on equipment.

For full product information please visit www.vapour-degreasing.com/prosolv5408e

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Medical Device Cleaning

ProSolv® 5408 high performance vapour degreasing solvent for medical device cleaning

Medical device cleaning

Critical cleaning is vital throughout the medical supply industry for safe, successful operations and procedures. Manufacturers of medical instruments, implants and other devices using metals, glass, ceramics and plastics must select a cleaning processes compatible with all these materials of construction, to remove oils and other contaminants from the manufacturing processes. The cleaning system must be proven to be safety critical and to leave no residues on the surfaces of the cleaned parts.

In this short article we discuss the benefits of condensation cleaning with ProSolv 5408e vapour degreasing solvent for medical device cleaning compared to water-based cleaning.

Water based cleaning options

Formulations for water based cleaners use combinations of surfactants to reduce the very high surface tension of water to allow penetration of the cleaning solution into minutes holes and very fine mechanical clearances. The solutions must solubilise oils, greases, cutting fluids, grinding and buffing compounds and remove particulate soils. Biocides are also present in these formulations to ensure no bioburden is carried over from the cleaning process.

After cleaning residues of chemicals must be removed or they may be a source of corrosion when the devices are in use. Multiple rinses in hot and cold de-ionised water using agitation of baskets or carriers or ultrasound to dilute and displace the cleaning liquids retained in minute holes, cavities and trapped between close tolerance metal surfaces.

Continuous production of high-quality deionised rinse water is extremely expensive, but the drying process is even more costly and environmentally challenging. Multiple cleaning and rinse tanks and drying ovens or tunnels need a lot of space and energy. Further controlled conditions are needed to cool parts after drying to prevent condensation of moisture, which can be growth media for bacteria, on the critically clean surfaces, before packing in sterile bags and containers for storage or shipping.

High output water based cleaning equipment can use conveyorised high pressure targeted spray tunnels for automated high-volume production with integrated “blow off” drying and conditioning tunnels.

For smaller scale operations systems are available using baskets in single cell dishwasher type equipment or open tanks. The latter can use manual or automated handling to progress baskets through the cleaning cycle using similar aqueous based chemical formulations with multiple deionised water rinses and a separate drying oven. These systems can process several baskets or carriers at a time so are only suitable for small batch production. In either case long process times will determine the size and complexity of installations.

Compare the complications of water-based processing to the simplicity and speed of vapour degreasing using ProSolv® 5408e solvents

Vapour degreasing or more properly condensation cleaning, is a proven process where a non-flammable halogenated solvent, safe for people and the environment is heated in the sump of a tank. Boiling solvent produces a dense vapour which is contained by condensation coils around the inner surfaces at the top of the tank. Solvent condensed on the coils is returned to the sump for reuse in a closed cycle.

Parts to be cleaned at ambient temperature are immersed in the vapour which condenses as solvent on the surfaces of the devices or parts in a continuous stream of perfectly clean solvent until the surfaces reaches vapour temperature when condensation ceases. Vapour degreasing uses only one tank with one liquid. Parts are cleaned, rinsed and dry in 3 to 5 minutes with parts hand hot ready for further processing, storage or packing into sterile packs for shipping.

ProSolv 5408e solvents were developed to provide superior critical cleaning performance for manufacturers of medical devices and equipment. The solvent is stable when used for vapour degreasing or cold dip cleaning and compatible with metals, including titanium, ceramics, glass and most plastics used in producing orthopaedic implants, dental, ophthalmic and surgical tools, lenses etc. ProSolv 5408e is a cost effective and sustainable solution to remove polar and non-polar soils and other contaminants and sets the standard for removal of machining and cutting oils, coolants, greases, grinding, buffing and polishing compounds, while leaving no residue.

Vapour degreasing and dip cleaning with ProSolv 5408e is a very effective steriliser of microbial contaminants. Exposing the microorganisms, which have cell walls made up of organic materials including lipids (Fats), to a powerful solvent is a very efficient disruptor of the cell walls. Once compromised the organism’s inner workings lose this protection and the organism dies reducing the bioburden.

ProSolv 5408e is also an excellent solvent carrier for organic or synthetic medical lubricant. This application for coating needles, cannulas and instruments needs consistent quality and evaporation rate to produce, comfortable, pain free insertion for patients.

In many medical applications oxygen and gas supply systems are needed and cleaning at installation and when extensions of pipework and fittings are added is vital for safety. ProSolv 5408e removes oil and organics leaving residue free, dry surfaces to standards approved by gas supply companies, and is compatible with all metals.

Clearly solvent cleaning and vapour degreasing with ProSolv 5408e is a better choice than water cleaning. Faster throughput, lower costs and sustainability to meet the unique challenges in achieving the high standards demanded for medical device manufacturing.

ProSolv 5408e is manufactured in UK with excellent customer service, technical support and training from qualified distributors throughout Europe.

For full product information please visit www.vapour-degreasing.com/prosolv-medical

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Latest News

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.