Latest Articles

Replacements for nPB

Envirotech Europe introduce low cost “drop in” replacements for nPB (n-propyl bromide) vapour degreasing solvents.

Bad news for your business. Coronavirus, Brexit, redundancies, social distancing reduced cash flow.

If that’s not enough and you are using nPB solvent that’s another problem to worry about as its use for vapour degreasing has been banned by the EU since July. Don’t panic it’s not too late to change and comply, as we have “drop in” replacements for nPB which are guaranteed to give the same results at no increase in your costs of usage. It is late but we can give you the information to easily make the change in a day without fuss.

You have questions – of course:

How can it be so simple?

The EnSolv range of stabilised nPB based vapour degreasing solvents has been the market leader in this field worldwide for many years. EnviroTech Europe, the manufacturers, know this product inside out with hundreds of satisfied users. We have been fighting the EU authorities for 20 years regarding classification, but with limited resources and the corporate giants with money to lose as EnSolv gained more and more of the market. Money talks so the Commission ignored the evidence and banned nPB for use as a vapour degreasing solvent with the sunset date in July 2020. If you are interested in the history, it is all explained in detail on our website.

With our extensive knowledge of user needs EnviroTech Europe, during the intervening years, have developed new compliant solvent formulations which are simple “drop-in” replacements.

No new equipment needed, guaranteed results and no extra costs to worry about.

We can’t guarantee that more changes will not happen in the future, but you will then have time to evaluate whether the new generation of wonder products which reduce global warming a smidgeon is worth the enormously increased costs.

Talk to us about whether EnSolv CC-A or ProSolv will be the best choice for your application. Advice, literature, changeover instructions are all available to make the change quickly, easily and at no extra cost of usage.

For more information about replacing nPB please visit:

www.vapour-degreasing.com/npb-replacement

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Corrosion Protection Spray – SuperCORR A

SuperCORR A corrosion protection spray protects and revitalises production machines during Coronavirus lockdowns.

Spraying a coating when shutting down machines, drives, conveyor chains and in control cabinets will prevent or displace condensation on exposed surfaces protecting against condensation. A further spray on reopening and restart displaces any surface moisture which may have accumulated and relubricates moving components.

SuperCORR A is a proprietary formulation containing no organic constituents. A combination of long lasting synthetic anticorrosion inhibitors and lubricants that protects metal components against moisture. This unique, water displacing lubricant is non-flammable and environment friendly.

Unexcelled in preventing corrosion and contamination on all surfaces in mechanical close tolerance slow moving components or electrical and electronic equipment used in humid conditions. Can be used on any metal surfaces to prevent flash rusting, microbial and other forms of corrosion.

SuperCORR A forms a super thin, hydrophobic, non-flammable lubricant film with anti-corrosion properties approximately 7 microns (0.007mm) in thickness and is compliant with U.S. EPA regulations, the European Union RoHS Directives

Conforms to MIL-DTL-87177B (Revised MIL-L-87177A) specifications.

For more information please visit www.corrosion-protect.com/supercorr-a To discuss the use of SuperCORR A to solve your corrosion protection problems please use the website contact form or phone us, we look forward to hearing from you.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

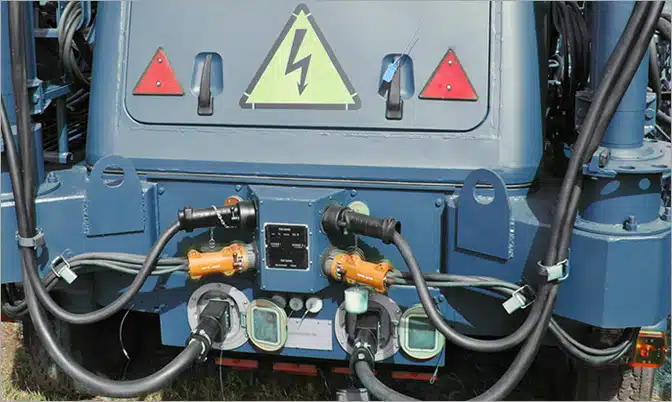

Improve connector maintenance on portable gas generators

Why using SuperCORR A for connector maintenance on portable gas generators improves electrical supplies in extreme conditions.

Portable generators maintain aircraft services at standings are connected and disconnected many times a day in extreme weather conditions.

These applications and locations test connector seals allowing dust or water to infiltrate. This with the flexing of the connecting cables allows sufficient movement between the metal surfaces of the connecting pins to produce fretting corrosion which reduces, interrupts or produces failures in electrical supply. Regular maintenance of electrical connectors and control systems is vital to be certain of uninterrupted supply.

SuperCORR A is an aerosol lubricant containing corrosion preventive compounds, which, as is the case with all lubricants, can be worn off over time.

A leading manufacturer of connectors tested SuperCORR A to see what the “life” of the lubricant was in a “rub test”. The typical test is 20,000 cycles, i.e. unplug, plug in is one cycle. The test results demonstrated that after 20,000 cycles there were no failures. It was decided to take it one more step and run the same tests for 200,000 cycles. The results again showed no indications of galling or scoring on the connectors at all. The connector looked and tested as good as new. This test was run under clean conditions in a laboratory but demonstrates the effectiveness of the protective lubricant in SuperCORR A.

As it meets Mil- MIL-DTL-87177B (Revised MIL-L-87177A) specifications SuperCORR A is used by the U.S. Air Force to protect the intricate workings of the F-16 Fighter Jet and by the U.S. Navy on the P 3 Orion electronic surveillance aircraft. Commercial aviation aircraft manufacturers recommend it for electrical and close metal mechanical application, especially where flights are in salt fog or high humidity.

Containing extremely long-lasting, proprietary anti-corrosive inhibitors SuperCORR Aprovides a superior lubrication coefficient and protects components against moisture, wear, general and fretting corrosion, surface static electricity, corona, and other electro migration problems. The super thin non-flammable lubricant film is only 7 microns (0.007 mm) thick and is formulated without sulphates, chlorides or halogens to meet the RoHS directive. It is unexcelled in preventing deterioration and contamination on all surfaces of electronic equipment.

Very fast drying environmentally acceptable solvents are used as carriers and propellants which will not affect most plastics, substrates, metals or other materials used in connector manufacture.

The aerosols are supplied with probes allowing access to pins and connector tubes where the low surface tension repels water, dirt dust and metal particles from blind holes and surfaces to produce thoroughly clean holes before a second application applies the lubricant film. Reconnection to the supply with cleaned sections of the connector ensures reliable operation even in the most testing of environments. This easy maintenance from one can of

SuperCORR A allows this essential task to be carried out in any conditions quickly, easily and securely.

For more information please visit www.corrosion-protect.com/supercorr-a To discuss the use of SuperCORR A to solve your problems please use the website contact form or phone us, we look forward to hearing from you.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Latest News

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.