Latest Articles

Avionic Corrosion Protection

Advanced Corrosion Protection for Avionic, Electrical and Mechanical Systems

Corrosion continues to present a significant challenge for the aerospace industry, affecting aircraft reliability, safety and lifecycle costs. Exposure to moisture, salt-laden air, temperature extremes and airborne contaminants places constant stress on aircraft systems – particularly avionic, electrical and mechanical components where performance margins are critical. Advanced corrosion protection solutions are therefore essential to maintaining airworthiness and operational readiness.

Super CORR A has been developed specifically to address these challenges, providing long-lasting corrosion protection for sensitive aerospace systems operating in harsh environments. Originally formulated to meet demanding military requirements, the product is now widely used across aerospace and defence applications where failure is not an option.

Addressing Corrosion in Aerospace Environments

Aircraft routinely operate in conditions that accelerate corrosion processes, including coastal regions, high-humidity climates and low-altitude missions over seawater. While structural corrosion is a well-recognised concern, corrosion affecting electrical connectors and mechanical flight controls can be equally disruptive.

In avionic and electronic systems, corrosion can increase contact resistance, degrade signal integrity and lead to intermittent faults that are difficult to diagnose. Mechanical components such as flap tracks, screw jacks and control linkages are also vulnerable, particularly where corrosion increases friction or wear, impacting control responsiveness and increasing maintenance requirements.

Dual-Function Protection and Lubrication

Super CORR A offers a combination of corrosion protection and dry lubrication, making it well suited to both electrical and mechanical aerospace applications. When applied, it forms an ultra-thin, hydrophobic protective film – approximately seven microns thick – that actively displaces moisture and inhibits oxidation without interfering with tight tolerances or electrical performance.

The non-hardening film provides sustained protection against atmospheric and salt-induced corrosion while also reducing wear and fretting in moving or vibration-prone components. Unlike traditional waxes or heavy oils, the coating remains stable over time and does not attract contaminants or build up on treated surfaces.

Protection for Avionic and Electrical Systems

Super CORR A is particularly effective in safeguarding aerospace electrical and electronic assemblies, including connectors, switches, wiring harnesses and avionic modules. By preventing corrosion at contact points, the product helps maintain signal integrity and reduces the risk of performance degradation caused by oxidation, electro-migration or fretting corrosion. It has been extensively tested by the US Airforce and proven to significantly reduce instances of “no fault found”.

The formulation is non-flammable, RoHS-compliant and free from sulphates, chlorides and halogens, making it suitable for use on sensitive electronic components and in regulated aerospace environments.

Safeguarding Mechanical Flight Controls

Mechanical flight control systems are exposed to continuous movement and environmental stress, particularly in aircraft operating in maritime or high-humidity conditions. Super CORR A provides a dry lubricating layer that protects these components from corrosion while simultaneously reducing friction and wear.

This dual action supports smoother operation of flight controls and helps extend maintenance intervals, contributing to improved aircraft availability and reduced lifecycle costs.

Supporting Avionic Maintenance and Operations

Supplied in an easy-to-apply aerosol format, Super CORR A is applied efficiently during routine inspections, maintenance and overhaul activities by many military and commercial aviation companies. Its ability to reach confined or hard-to-access areas makes it especially valuable for aerospace maintenance, repair and operations (MRO) teams.

Super CORR A helps aerospace operators reduce unplanned downtime, protect high-value assets and maintain consistent performance in demanding operating environments.

Specialist Barrier Film Corrosion Protection Spray

Super CORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors.

The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive. It complies with MIL-DTL-87177B (revised MIL-L-87177A) Type I, Grade B.

Super CORR A forms an airtight seal preventing damage to electronics and other surfaces caused by exposure to acid gases such as Sulfur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulfide (H2S), Ammonia (NH3), Chlorine based gases (CL12), and the thermal decomposition by product of HFC-227ea used in fire suppression systems, Hydrogen Fluoride (HF).

The use of Super CORR A cannot only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace damaged equipment or a component that failed because of corrosion.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

- Non-flammable.

PACKAGING

- Boxes of 12 – 340gm (12 oz fluid) aerosol cans.

- 5kg can of liquid.

INDUSTRY APPROVED

- Complies with MIL-DTL-87177B (revised MIL-L-87177A) Type I, Grade B.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

EnviroTech Europe | 2026 online brochure is now available

Advanced solutions for solvent cleaning, vapour degreasing, corrosion protection and metal surface cleaning

EnviroTech Europe supply approved vapour degreasing solvents, solvent cleaners and corrosion protection products. We offer a range of metal and substrate cleaning and protection formulations tailored to your industry, which are cost effective, energy efficient, safe for operators and the environment.

Our products are used in the following industries:

· Automotive and Motorsport

· Avionics and Aerospace

· Electronics and Electrical

· Farming and Agricultural

· General Cleaning

· Industrial and Manufacturing

· Marine and Maritime

· Mechanical Engineering

· Medical Device Manufacturing

· Military and Defence

· Oxygen Cleaning

· Power Generation

· Railways and Transport

Our technical and sales staff can offer advice on legislative changes which affect your industry, ensuring your solvent cleaning, vapour degreasing and corrosion protection solutions stay within regulatory boundaries.

We can supply Material Safety Data Sheets, independent laboratory reports, product samples and further assistance. EnviroTech Europe is accredited to ISO 9001:2015 for the distribution of specialist metal cleaning and corrosion protection products.

FURTHER INFORMATION

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Video: Order Before December 31st 2025 To Secure Your Replacements for 3M™ Novec™ Solvents

Order Before December 31st 2025 To Secure Your Replacements for 3M™ Novec™ Solvents.

In March 2025, 3M™ officially closed final order dates and confirmed the discontinuation of its Novec™ Engineered Fluids, with supplies ceasing by 31 December 2025. As this deadline looms, companies in electronics, aerospace, medical devices, precision engineering, and related sectors must act swiftly to prevent supply chain disruptions and rising costs.

Why You Must Act Now

- Imminent Shortages & Rising Costs: Many 3M™ Novec™ grades are already becoming unavailable, with others facing long lead times and inflated prices as stocks dwindle.

- Supply Chain Shortage: Final Orders for most 3M™ Novec™ grades were on 31st March 2025 and global stocks are diminishing fast.

- Operational Risks: Delays in cleaning and degreasing processes could severely impact manufacturing timelines.

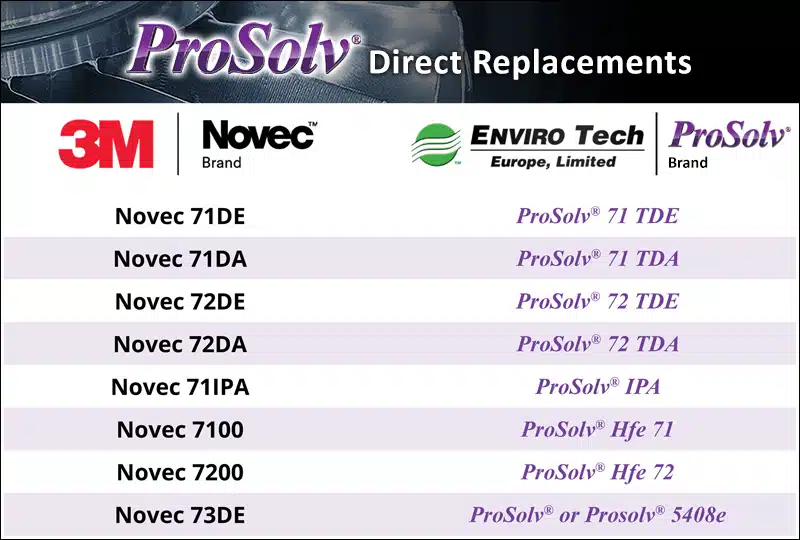

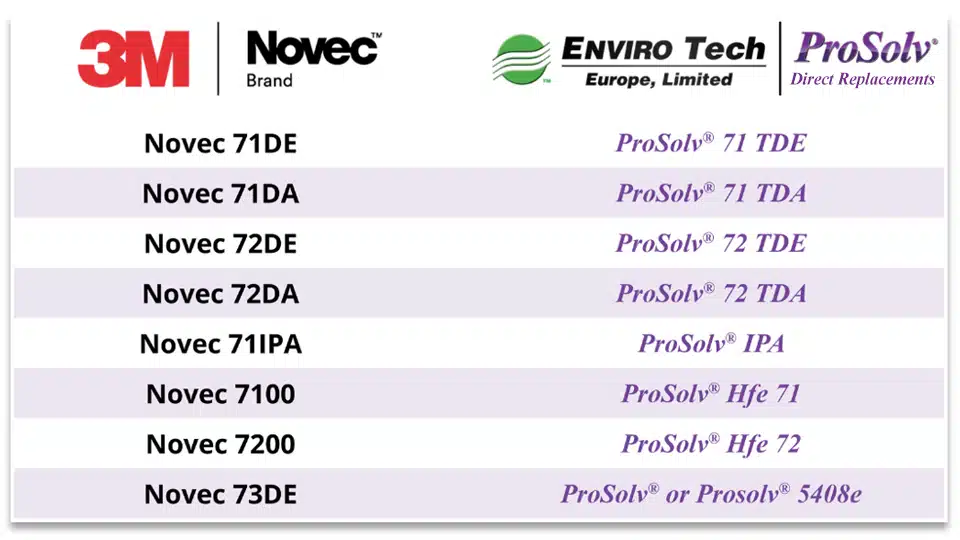

Switch to ProSolv® Direct Replacements

EnviroTech Europe has introduced ProSolv® Direct Replacements for 3M™ Novec™ Engineered Fluids – formulated as chemically exact, drop-in alternatives for all Novec grades. These solvents are designed to:

- Match performance (cleaning power, non-flammability, GWP & ODP levels).

- Require no changes to existing vapour degreasing equipment.

- Provide long-term availability and peace of mind through the transition.

Future-Proof Your Process with PFAS-Free Solvents

EnviroTech Europe also offers PFAS‑Free options such as ProSolv®5408e. This next-generation solvent aligns with emerging regulations and evolving environmental goals – ensuring sustainability without sacrificing performance. With zero ODP (Ozone Depletion Potential) and near zero GWP (Global Warming Potential).

Testing

- Flash Point ASTM D3828 and ASTM D93.

- Flammable limits ASTM E918.

- Stock Loss ARP1755B.

- IGA Intergranular attack.

- Stress corrosion of titanium alloys ASTM F945-12.

- Hydrogen Embrittlement ASTM F519-17a.

Expert Support to Keep You Running

EnviroTech Europe backs the ProSolv® Direct Replacements line with a range of services:

- Free on-site assessments, cleaning trials, sample materials and technical consultations.

- Ongoing regulatory support through global distributors.

- Long-term supply stability, backed by UK-based manufacturing and logistics.

Your Next Steps: Secure Supply, Minimise Risk

- Review your current Novec™ inventory.

- Contact EnviroTech Europe for an on-site assessment or to claim your free product trial.

- Evaluate ProSolv® matches – including standard and PFAS-Free blends.

- Plan trials and qualifying tests to identify ideal replacements.

- Switch to the appropriate ProSolv® alternative and enjoy a seamless change from 3M.

The Time To Act Is Now

EnviroTech Europe provide performance-equivalent 3M™ Novec™ alternatives, backed by full technical support. Secure your supply chain and preserve the integrity of your precision-cleaning processes by transitioning to the ProSolv® Direct Replacements today.

FURTHER INFORMATION

Please visit our website www.envirotech-europe.com/replacements-for-3M-Novec-engineered-fluids for more information about replacing 3M™ Novec™ solvents.

Visit www.envirotech-europe.com/prosolv5408e for information about our next-generation PFAS-free vapour degreasing solvent cleaners. For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

Share this page:

Related Posts

Latest News

Avionic Corrosion Protection

Advanced Corrosion Protection for Avionic, Electrical and Mechanical Systems

Corrosion continues to present a significant challenge for the aerospace industry, affecting aircraft reliability, safety and lifecycle costs. Exposure to moisture, salt-laden air, temperature extremes and airborne contaminants places constant stress on aircraft systems – particularly avionic, electrical and mechanical components where performance margins are critical. Advanced corrosion protection solutions are therefore essential to maintaining airworthiness and operational readiness.

Super CORR A has been developed specifically to address these challenges, providing long-lasting corrosion protection for sensitive aerospace systems operating in harsh environments. Originally formulated to meet demanding military requirements, the product is now widely used across aerospace and defence applications where failure is not an option.

Addressing Corrosion in Aerospace Environments

Aircraft routinely operate in conditions that accelerate corrosion processes, including coastal regions, high-humidity climates and low-altitude missions over seawater. While structural corrosion is a well-recognised concern, corrosion affecting electrical connectors and mechanical flight controls can be equally disruptive.

In avionic and electronic systems, corrosion can increase contact resistance, degrade signal integrity and lead to intermittent faults that are difficult to diagnose. Mechanical components such as flap tracks, screw jacks and control linkages are also vulnerable, particularly where corrosion increases friction or wear, impacting control responsiveness and increasing maintenance requirements.

Dual-Function Protection and Lubrication

Super CORR A offers a combination of corrosion protection and dry lubrication, making it well suited to both electrical and mechanical aerospace applications. When applied, it forms an ultra-thin, hydrophobic protective film – approximately seven microns thick – that actively displaces moisture and inhibits oxidation without interfering with tight tolerances or electrical performance.

The non-hardening film provides sustained protection against atmospheric and salt-induced corrosion while also reducing wear and fretting in moving or vibration-prone components. Unlike traditional waxes or heavy oils, the coating remains stable over time and does not attract contaminants or build up on treated surfaces.

Protection for Avionic and Electrical Systems

Super CORR A is particularly effective in safeguarding aerospace electrical and electronic assemblies, including connectors, switches, wiring harnesses and avionic modules. By preventing corrosion at contact points, the product helps maintain signal integrity and reduces the risk of performance degradation caused by oxidation, electro-migration or fretting corrosion. It has been extensively tested by the US Airforce and proven to significantly reduce instances of “no fault found”.

The formulation is non-flammable, RoHS-compliant and free from sulphates, chlorides and halogens, making it suitable for use on sensitive electronic components and in regulated aerospace environments.

Safeguarding Mechanical Flight Controls

Mechanical flight control systems are exposed to continuous movement and environmental stress, particularly in aircraft operating in maritime or high-humidity conditions. Super CORR A provides a dry lubricating layer that protects these components from corrosion while simultaneously reducing friction and wear.

This dual action supports smoother operation of flight controls and helps extend maintenance intervals, contributing to improved aircraft availability and reduced lifecycle costs.

Supporting Avionic Maintenance and Operations

Supplied in an easy-to-apply aerosol format, Super CORR A is applied efficiently during routine inspections, maintenance and overhaul activities by many military and commercial aviation companies. Its ability to reach confined or hard-to-access areas makes it especially valuable for aerospace maintenance, repair and operations (MRO) teams.

Super CORR A helps aerospace operators reduce unplanned downtime, protect high-value assets and maintain consistent performance in demanding operating environments.

Specialist Barrier Film Corrosion Protection Spray

Super CORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors.

The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive. It complies with MIL-DTL-87177B (revised MIL-L-87177A) Type I, Grade B.

Super CORR A forms an airtight seal preventing damage to electronics and other surfaces caused by exposure to acid gases such as Sulfur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulfide (H2S), Ammonia (NH3), Chlorine based gases (CL12), and the thermal decomposition by product of HFC-227ea used in fire suppression systems, Hydrogen Fluoride (HF).

The use of Super CORR A cannot only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace damaged equipment or a component that failed because of corrosion.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

- Non-flammable.

PACKAGING

- Boxes of 12 – 340gm (12 oz fluid) aerosol cans.

- 5kg can of liquid.

INDUSTRY APPROVED

- Complies with MIL-DTL-87177B (revised MIL-L-87177A) Type I, Grade B.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

EnviroTech Europe | 2026 online brochure is now available

Advanced solutions for solvent cleaning, vapour degreasing, corrosion protection and metal surface cleaning

EnviroTech Europe supply approved vapour degreasing solvents, solvent cleaners and corrosion protection products. We offer a range of metal and substrate cleaning and protection formulations tailored to your industry, which are cost effective, energy efficient, safe for operators and the environment.

Our products are used in the following industries:

· Automotive and Motorsport

· Avionics and Aerospace

· Electronics and Electrical

· Farming and Agricultural

· General Cleaning

· Industrial and Manufacturing

· Marine and Maritime

· Mechanical Engineering

· Medical Device Manufacturing

· Military and Defence

· Oxygen Cleaning

· Power Generation

· Railways and Transport

Our technical and sales staff can offer advice on legislative changes which affect your industry, ensuring your solvent cleaning, vapour degreasing and corrosion protection solutions stay within regulatory boundaries.

We can supply Material Safety Data Sheets, independent laboratory reports, product samples and further assistance. EnviroTech Europe is accredited to ISO 9001:2015 for the distribution of specialist metal cleaning and corrosion protection products.

FURTHER INFORMATION

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Video: Order Before December 31st 2025 To Secure Your Replacements for 3M™ Novec™ Solvents

Order Before December 31st 2025 To Secure Your Replacements for 3M™ Novec™ Solvents.

In March 2025, 3M™ officially closed final order dates and confirmed the discontinuation of its Novec™ Engineered Fluids, with supplies ceasing by 31 December 2025. As this deadline looms, companies in electronics, aerospace, medical devices, precision engineering, and related sectors must act swiftly to prevent supply chain disruptions and rising costs.

Why You Must Act Now

- Imminent Shortages & Rising Costs: Many 3M™ Novec™ grades are already becoming unavailable, with others facing long lead times and inflated prices as stocks dwindle.

- Supply Chain Shortage: Final Orders for most 3M™ Novec™ grades were on 31st March 2025 and global stocks are diminishing fast.

- Operational Risks: Delays in cleaning and degreasing processes could severely impact manufacturing timelines.

Switch to ProSolv® Direct Replacements

EnviroTech Europe has introduced ProSolv® Direct Replacements for 3M™ Novec™ Engineered Fluids – formulated as chemically exact, drop-in alternatives for all Novec grades. These solvents are designed to:

- Match performance (cleaning power, non-flammability, GWP & ODP levels).

- Require no changes to existing vapour degreasing equipment.

- Provide long-term availability and peace of mind through the transition.

Future-Proof Your Process with PFAS-Free Solvents

EnviroTech Europe also offers PFAS‑Free options such as ProSolv®5408e. This next-generation solvent aligns with emerging regulations and evolving environmental goals – ensuring sustainability without sacrificing performance. With zero ODP (Ozone Depletion Potential) and near zero GWP (Global Warming Potential).

Testing

- Flash Point ASTM D3828 and ASTM D93.

- Flammable limits ASTM E918.

- Stock Loss ARP1755B.

- IGA Intergranular attack.

- Stress corrosion of titanium alloys ASTM F945-12.

- Hydrogen Embrittlement ASTM F519-17a.

Expert Support to Keep You Running

EnviroTech Europe backs the ProSolv® Direct Replacements line with a range of services:

- Free on-site assessments, cleaning trials, sample materials and technical consultations.

- Ongoing regulatory support through global distributors.

- Long-term supply stability, backed by UK-based manufacturing and logistics.

Your Next Steps: Secure Supply, Minimise Risk

- Review your current Novec™ inventory.

- Contact EnviroTech Europe for an on-site assessment or to claim your free product trial.

- Evaluate ProSolv® matches – including standard and PFAS-Free blends.

- Plan trials and qualifying tests to identify ideal replacements.

- Switch to the appropriate ProSolv® alternative and enjoy a seamless change from 3M.

The Time To Act Is Now

EnviroTech Europe provide performance-equivalent 3M™ Novec™ alternatives, backed by full technical support. Secure your supply chain and preserve the integrity of your precision-cleaning processes by transitioning to the ProSolv® Direct Replacements today.

FURTHER INFORMATION

Please visit our website www.envirotech-europe.com/replacements-for-3M-Novec-engineered-fluids for more information about replacing 3M™ Novec™ solvents.

Visit www.envirotech-europe.com/prosolv5408e for information about our next-generation PFAS-free vapour degreasing solvent cleaners. For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

Share this page:

Related Posts

Next-Generation Vapour Degreasing Solvent For Medical Device Cleaning

Next-Generation Vapour Degreasing Solvent For Medical Device Cleaning

Precision cleaning plays a crucial role in medical device manufacturing, reinforcing both product quality and patient safety. Effective and validated cleaning processes are essential to prevent contamination and maintain compliance with industry standards. As global demand for medical devices grows, manufacturers must implement reliable, efficient cleaning strategies to uphold the highest standards of safety and performance.

The cleaning stage in medical device manufacturing removes oils, particulates, drawing/forming lubricants and a range of other contaminants, which is essential to achieving the required levels of product quality and biocompatibility. Even trace impurities can affect device performance or compromise patient safety, making thorough and validated cleaning essential to eliminate potential risks.

Medical device cleaning using vapour degreasing with ultrasonics

Ultrasonic vapour degreasing is an ideal process for cleaning medical instruments because it combines three powerful cleaning mechanisms in a self-contained, controlled, residue-free environment. The process uses non-flammable solvent vapour to dissolve contaminants, followed by solvent immersion and intense ultrasonic agitation, to lift microscopic particles from complex geometries, internal passages, and difficult to reach crevices, essential for cleaning medical device instruments and implants.

The parts are immersed in clean solvent that has been contained in the system and distilled. This ensures the consistent, repeatable removal of all contaminants, meeting the stringent precision cleanliness standards required for sterilization. From an engineering perspective, the closed-loop vapour degreasing process offers significant advantages in process control and cost-efficiency. Unlike open-bath or aqueous cleaning, the continuous distillation within the degreaser ensures the purity of the final rinse solvent remains consistent, virtually eliminating batch-to-batch variation, which is crucial for successful process validation in the medical sector.

Modern medical devices are complex assemblies of metals, ceramics, polymers and glass. During each phase of machining and finishing, oils, lubricants, polishing compounds, and particulates are introduced, which must be thoroughly eliminated prior to assembly or sterilisation. The vapour degreasing process, in unison with ProSolv®5408e, offers a proven and effective way to clean medical instruments, with parts emerging clean, dry, residue-free and ready for further processing within minutes.

The solvent of choice for the critical cleaning in the medical device cleaning industry

ProSolv®5408e is a high-performance, PFAS-free vapour degreasing solvent that delivers residue-free cleaning, essential for cleaning orthopaedic implants, dental, ophthalmic, surgical instruments, optical lenses and other medical devices. A next-generation solution which combines exceptional performance, environmental responsibility, and acts as a seamless replacement for discontinued 3M™ Novec™ fluids, such as Novec 71DE, 72DE and 73DE. It allows medical manufacturers to maintain the very highest standards.

ProSolv®5408e has exceptionally low surface tension and high solvency power, allowing it to penetrate deep into micron sized holes and close contact surfaces, effectively removing contaminants whilst remaining compatible with a wide range of metals and plastics. The solvent is stable when used for vapour degreasing or cold dip cleaning and compatible with metals, including titanium, ceramics, glass and most plastics.

PFAS-free, high performance vapour degreasing with Zero Ozone Depletion Potential (ODP) and Global Warming Potential (GWP) of less than 1

ProSolv®5408e is an advanced, premium quality cleaning solvent designed to meet the highest environmental and performance standards. Completely PFAS-free (free from Per- and polyfluoroalkyl substances), it features zero Ozone Depletion Potential (ODP) and ultra-low Global Warming Potential, making it a truly future-proof solution.

ProSolv®5408e can be used in most solvent cleaning systems, one tank vapour degreasing or multi tank immersion / vapour tank systems using ultrasonics or flush cleaning. Components emerge dry, eliminating the need for secondary drying or deionised water systems. Ideal for these safety-critical cleaning operations, matching performance expectations from the medical device production sector.

ProSolv®5408e provides superior critical cleaning performance and is a cost effective and sustainable solution for the removal of polar and non-polar soils and other contaminants, setting the standard for removing of machining and cutting oils, coolants, greases, grinding, buffing and polishing compounds, while leaving no residue. It’s low boiling point directly reduces energy consumption compared to high-boiling solvents or heated aqueous systems, contributing to a lower carbon footprint and operating cost. The complete lack of a water-based drying step eliminates the need for expensive ovens or DI water systems, translating into shorter cycle times (typically 3-5 minutes) and a reduced footprint on the manufacturing floor.

Replacing discontinued 3M™ Novec™ fluids

The withdrawal of 3M™ Novec™ Engineered Fluids has left many manufacturers searching for compliant alternatives. ProSolv®5408e is engineered to fill that gap, offering a direct replacement for 3M™ Novec™ 71DE, 72DE and 73DE.

Testing

- Flash Point ASTM D3828 and ASTM D93.

- Flammable limits ASTM E918.

- Stock Loss ARP1755B.

- IGA Intergranular attack.

- Stress corrosion of titanium alloys ASTM F945-12.

- Hydrogen Embrittlement ASTM F519-17a.

Benefits of using ProSolv®5408e

- Compatible with metals, ceramics, glass and engineering plastics.

- Fast cycle times: 3-5 minutes per batch.

- PFAS-Free (Per- and polyfluoroalkyl substances).

- RoHS compliant.

- Low Carbon footprint due to the low boiling point of (46°C).

- Energy efficient: No heated rinses or drying ovens required.

- Stable with no additives, no testing required.

- Consistent results: Continuous solvent distillation maintains purity.

- Minimal non-volatile residue (>10ppm).

- Very low surface tension for penetration into the micron level crevices and holes, efficient cleaning in tight to reach places and complex geometries.

- Easy process monitoring with minimal effort and minimal waste generation, easy reclamation for reuse.

- High Solvency (KB Value 98) for a variety of contaminants.

Safe for users and the environment

- Safe for the environment, zero Ozone Depletion Potential (ODP).

- GWP of less than 1, AR4 100yr Integrated Time Horizon (ITH).

- Non-flammable (No Flash Point).

- Not classified as a carcinogen.

- Non-hazardous for transportation.

Conclusion

As medical device production faces stricter environmental and regulatory demands, ProSolv®5408e offers a powerful, sustainable and technically advanced solution for critical cleaning applications. It delivers rapid, residue-free cleaning, broad material compatibility and low environmental impact, making it an ideal choice for manufacturers seeking to maintain the highest levels of cleanliness. ProSolv®5408e provides a rare combination of cleaning power, safety and regulatory alignment, allowing users to transition confidently away from high-impact or discontinued solvents without compromising performance.

FURTHER INFORMATION

Please visit our website www.envirotech-europe.com/replacements-for-3M-Novec-engineered-fluids for more information about replacing 3M™ Novec™ solvents.

Visit www.envirotech-europe.com/prosolv5408e for information about our next-generation PFAS-free vapour degreasing solvent cleaners. For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

Share this page:

Related Posts

SuperCORR A Is The Ultimate Defence Against Corrosion

Corrosion protection for a range of industries

Super CORR A corrosion protection spray was originally designed to prevent electrical and electronic aviation components from systems failures caused by corrosion.

Super CORR A corrosion protection spray was originally designed to prevent electrical and electronic aviation components from systems failures caused by corrosion. It was developed within strict safety specifications and has become the gold standard for corrosion protection within the aerospace industry.

Super CORR A gives industry approved, superior protection against moisture, wear, general and fretting corrosion, static electricity, corona and other electro migration problems. It’s unique ability to displace water and provide a performance enhancing level of corrosion protection, makes it very powerful at preventing corrosion of electronic and electrical equipment in demanding industries like aerospace, rail and road transport, marine, offshore oil and gas industries, wastewater treatment plants, electrical power facilities, air conditioning units and paper mills. It is particularly effective in environments where corrosive gases such as salt laden air or hydrogen sulphide are present.

Super CORR A is unexcelled in preventing failures of electrical systems and electronic equipment caused by corrosion as well as preventing the corrosion of metal components surfaces, including those of components comprised of dissimilar metals such as those found in aerospace environments. It’s ability to displace water from exposed contacts can ensure reliable operation in extreme conditions.

Specialist barrier film corrosion protection spray

Super CORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors. The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive. It complies with MIL-DTL-87177B (revised MIL-L-87177A) Type I, Grade B.

Super CORR A is a non-flammable “self-healing” ultra-thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack, is not a wax or oil-based product and is formulated without sulphates, chlorides or halogens. It forms an airtight seal preventing damage to electronics and other surfaces caused by exposure to acid gases such as Sulfur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulfide (H2S), Ammonia (NH3), Chlorine based gases (CL12), and the thermal decomposition by product of HFC-227ea used in fire suppression systems, Hydrogen Fluoride (HF).

The use of Super CORR A cannot only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace damaged equipment or a component that failed because of corrosion.

Super CORR A is packaged in aerosol cans making application to component parts easy in difficult locations and conditions. Unpainted mild steel will not rust on exterior surfaces directly exposed to sea water environments for at least 6 months, protecting electrical connectors, switches, chains, drive shafts from corrosion while maintaining lubrication on moving surfaces.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

- Non-flammable.

PACKAGING

- Boxes of 12 – 340gm (12 oz fluid) aerosol cans.

- 5kg can of liquid.

PACKAGING

- Complies with MIL-DTL-87177B (revised MIL-L-87177A) Type I, Grade B.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Video: Drop-in replacements for 3M™ Novec™ Engineered Fluids from EnviroTech Europe

Drop-in replacements for 3M™ Novec™ Engineered Fluids

Supplies of 3M™ Novec™ Engineered Fluids will end by the 31st of December 2025, with final order dates having officially closed in March 2025. Companies within the aerospace, electronics, medical device, precision engineering and many other industries must act now to prevent supply chain disruptions and rising costs.

The ProSolv® Direct Replacements range from EnviroTech Europe offers approved, chemically exact direct replacements for 3M™ Novec™ engineered fluids, and this range will be available well after 3M™ leave the market, providing you with peace of mind and control over your supply of cleaning solvents.

EnviroTech Europe understands the uniqueness of every precision cleaning application and will work with you to find the right solution for your current needs. We also provide free on-site visits, technical support and cleaning trials when required, and can supply a range of vapour degreasing equipment to suit your product.

Why You Must Act Now

- Imminent Shortages & Rising Costs: Many 3M™ Novec™ grades are already becoming unavailable, with others facing long lead times and inflated prices as stocks dwindle.

- Supply Chain Shortage: Final Orders for most 3M™ Novec™ grades were on 31st March 2025 and global stocks are diminishing fast.

- Operational Risks: Delays in cleaning and degreasing processes could severely impact manufacturing timelines.

Switch to ProSolv® Direct Replacements

ProSolv® Direct Replacements are range of direct replacements for 3M™ Novec™ Engineered formulated as chemically exact, drop-in alternatives for all Novec grades. These solvents are designed to:

- Match performance (cleaning power, non-flammability, GWP & ODP levels).

- Require no changes to existing vapour degreasing equipment.

- Provide long-term availability and peace of mind through the transition.

Specialist Support to Keep You Running

EnviroTech Europe backs the ProSolv® Direct Replacements line with a range of services:

- Free on-site assessments, cleaning trials, sample materials and technical consultations.

- Ongoing regulatory support through global distributors.

- Long-term supply stability, backed by UK-based manufacturing and logistics.

Your Next Steps: Secure Supply, Minimise Risk

- Review your current Novec™ inventory.

- Contact EnviroTech Europe for an on-site assessment or to claim your free product trial.

- Evaluate ProSolv® matches – including standard and PFAS-Free blends.

- Plan trials and qualifying tests to identify ideal replacements.

- Place orders now, while the 3M™ Novec™ supply diminishes and before the price spikes further.

The Time To Act Is Now

EnviroTech Europe provide performance-equivalent 3M™ Novec™ alternatives, backed by full technical support. Secure your supply chain and preserve the integrity of your precision-cleaning processes by transitioning to the ProSolv® Direct Replacements today.

Future-Proof Your Process with PFAS-Free Solvents

Looking to the future EnviroTech Europe also supply Next-Generation PFAS-free solvent cleaning solutions like ProSolv®5408e, and ProSolv® AS-1, both with Zero Ozone Depletion Potential, and Near Zero Global Warming Potential.

ProSolv®5408e Testing

- Flash Point ASTM D3828 and ASTM D93.

- Flammable limits ASTM E918.

- Stock Loss ARP1755B.

- IGA Intergranular attack.

- Stress corrosion of titanium alloys ASTM F945-12.

- Hydrogen Embrittlement ASTM F519-17a.

FURTHER INFORMATION

Please visit our website www.envirotech-europe.com/replacements-for-3M-Novec-engineered-fluids for more information about replacing 3M™ Novec™ solvents.

Visit www.envirotech-europe.com/prosolv5408e for information about our next-generation PFAS-free vapour degreasing solvent cleaners. For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

Share this page:

Related Posts

Critical cleaning in the aerospace industry

Next-generation, PFAS-free vapour degreasing solvent for critical cleaning in the aerospace industry

In the demanding world of aircraft and aerospace component manufacturing, highly effective precision cleaning is vital from production to final finishing. Components must be thoroughly degreased with no residue left behind.

Vapour degreasing remains the gold standard method for efficiency, safety, and performance, delivering superior cleaning power, using less energy, and requiring minimal floor space. The latest generation of vapour degreasing solvent cleaners offer high performance, environmentally friendly solutions, designed especially for the aerospace and aircraft industry, where critical cleaning is essential for the removal of heavy greases, oils, waxes, silicones, and non-polar flux residues.

EnviroTech Europe supply premium quality precision cleaning solvents, manufactured in the UK to the highest quality standards under strict quality control procedures. Advanced cleaning solutions that are safe, sustainable, and cost-effective – trusted by industry leaders across the aerospace sectors.

The Future of High-Performance, PFAS-free Cleaning

ProSolv®5408e is an advanced, next-generation cleaning solvent designed to meet the highest environmental and performance standards. Completely PFAS-free (free from Per- and polyfluoroalkyl substances), it features zero Ozone Depletion Potential (ODP) and ultra-low Global Warming Potential, making it a truly future-proof solution.

ProSolv®5408e enables the powerful removal of organic residues and oils, while remaining compatible with a wide range of plastics and metals. Exceptionally low surface tension and high solvency power enable it to penetrate deep into tight spaces, complex geometries, blind holes, and even micron-sized openings – ensuring thorough and reliable component cleaning.

Versatile and efficient for modern cleaning Systems

ProSolv®5408e is compatible with most solvent cleaning systems including one-tank or multi-tank immersion and vapour degreasing equipment, using ultrasonics or flush cleaning. It delivers outstanding performance in removing a broad spectrum of organic soils. Designed for energy efficiency and fast cycle times, it ensures low solvent losses, easy handling, and reduced environmental impact – helping you cut operating costs without compromising on cleaning quality. A few examples of its many applications are discussed below:

Bonding of honeycomb sections for composites

Removal of all contamination from aluminium honeycomb prior to epoxy resin bonding of the formed aluminium skin to produce lightweight high tensile structures for applications such as leading edges on aircraft wings and wind turbine blades. ProSolv®5408e is fully tested to aircraft industry standards.

Cleaning for crack and fault testing of welds and castings

Another common use in the aircraft industry is in the cleaning of castings and metal fabrications before the use of NDT (non-destructive testing) crack detection fluids. Removal of all surface contamination is vital to expose faults. Vapour degreasing and vapour liquid cleaning with ultrasonics is a favoured method due to the excellent solubility of oils, greases and other soils, using one tank with very fast processing, and resulting in the parts emerging completely clean and dry. This is particularly relevant as part of the maintenance procedure for refurbishment of aircraft landing gearswhere surfaces can be heavily contaminated by hard to remove hydraulic oils, rubber and cement dust and grease.

Critical cleaning of oxygen and gas systems

EnviroTech Europe has a series of guides to using ProSolv®5408e for component cleaning to Oxygen standards and recommended cleaning methods involved, available on request.

Replacement for 3M™ Novec™ 72DE and 73DE Engineered Fluid

ProSolv®5408e is also a PFAS-Free direct replacement for 3M™ Novec™ 72DE and 73DE engineered fluids, used prominently in the aerospace, aviation and electronics industries, which are due to be phased out by the end of 2025.

Testing

- Flash Point ASTM D3828 and ASTM D93.

- Flammable limits ASTM E918.

- Stock Loss ARP1755B.

- IGA Intergranular attack.

- Stress corrosion of titanium alloys ASTM F945-12.

- Hydrogen Embrittlement ASTM F519-17a.

FURTHER INFORMATION

Visit www.envirotech-europe.com/prosolv5408e for information about our next-generation PFAS-free vapour degreasing solvent cleaners. For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

Share this page:

Related Posts

Act Now to Secure Your Replacements for 3M™ Novec™ Engineered Fluids

Act Now to Secure Your Replacements for 3M™ Novec™ Engineered Fluids.

In March 2025, 3M™ officially closed final order dates and confirmed the discontinuation of its Novec™ Engineered Fluids, with supplies ceasing by 31 December 2025. As this deadline looms, companies in electronics, aerospace, medical devices, precision engineering, and related sectors must act swiftly to prevent supply chain disruptions and rising costs.

Why You Must Act Now

- Imminent Shortages & Rising Costs: Many 3M™ Novec™ grades are already becoming unavailable, with others facing long lead times and inflated prices as stocks dwindle.

- Supply Chain Shortage: Final Orders for most 3M™ Novec™ grades were on 31st March 2025 and global stocks are diminishing fast.

- Operational Risks: Delays in cleaning and degreasing processes could severely impact manufacturing timelines.

Switch to ProSolv® Direct Replacements

EnviroTech Europe has introduced ProSolv® Direct Replacements for 3M™ Novec™ Engineered Fluids – formulated as chemically exact, drop-in alternatives for all Novec grades. These solvents are designed to:

- Match performance (cleaning power, non-flammability, GWP & ODP levels).

- Require no changes to existing vapour degreasing equipment.

- Provide long-term availability and peace of mind through the transition.

Future-Proof Your Process with PFAS-Free Solvents

EnviroTech Europe also offers PFAS‑Free options such as ProSolv®5408e. This next-generation solvent aligns with emerging regulations and evolving environmental goals – ensuring sustainability without sacrificing performance. With zero ODP (Ozone Depletion Potential) and near zero GWP (Global Warming Potential).

ProSolv®5408e Testing

- Flash Point ASTM D3828 and ASTM D93.

- Flammable limits ASTM E918.

- Stock Loss ARP1755B.

- IGA Intergranular attack.

- Stress corrosion of titanium alloys ASTM F945-12.

- Hydrogen Embrittlement ASTM F519-17a.

Expert Support to Keep You Running

EnviroTech Europe backs the ProSolv® Direct Replacements line with a range of services:

- Free on-site assessments, cleaning trials, sample materials and technical consultations.

- Ongoing regulatory support through global distributors.

- Long-term supply stability, backed by UK-based manufacturing and logistics.

Your Next Steps: Secure Supply, Minimise Risk

- Review your current Novec™ inventory.

- Contact EnviroTech Europe for an on-site assessment or to claim your free product trial.

- Evaluate ProSolv® matches – including standard and PFAS-Free blends.

- Plan trials and qualifying tests to identify ideal replacements.

- Place orders now, while the 3M™ Novec™ supply diminishes and before the price spikes further.

The Time To Act Is Now

EnviroTech Europe provide performance-equivalent 3M™ Novec™ alternatives, backed by full technical support. Secure your supply chain and preserve the integrity of your precision-cleaning processes by transitioning to the ProSolv® Direct Replacements today.

FURTHER INFORMATION

Please visit our website www.envirotech-europe.com/replacements-for-3M-Novec-engineered-fluids for more information about replacing 3M™ Novec™ solvents.

Visit www.envirotech-europe.com/prosolv5408e for information about our next-generation PFAS-free vapour degreasing solvent cleaners. For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

Share this page:

Related Posts