Latest Articles

Discontinued 3M™ Novec™ Engineered Fluids

DISCONTINUED 3M™ NOVEC™ ENGINEERED FLUIDS – SWITCH SEAMLESSLY TO PROSOLV® DIRECT REPLACEMENTS

In December 2022, 3M™ announced their plans to discontinue their Novec™ range of PFAS substances (per- and polyfluoroalkyl) in its product line. Final order dates were on March 31st 2025 and the supply of these products will end on December 31st 2025.

This affects the following 3M™ product lines:

3M™ Novec™ Engineered Fluids 3M™

Fluorinert™ Electronic Liquids

The phase-out has left many industries, including electronics, aerospace, medical, and precision engineering, scrambling for viable replacements that match the performance characteristics of Novec™ products, and businesses around the world who rely on these solvents for vapour degreasing applications are now seeking reliable alternatives.

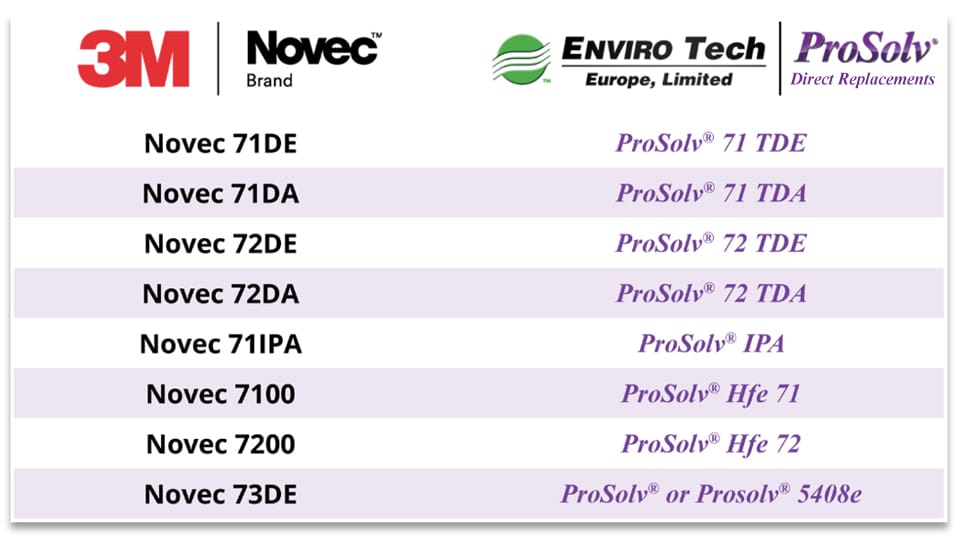

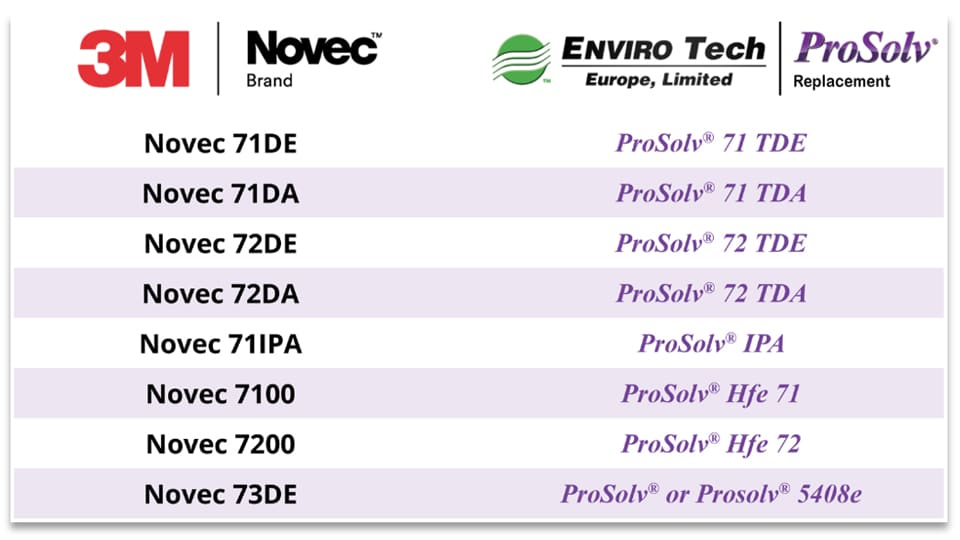

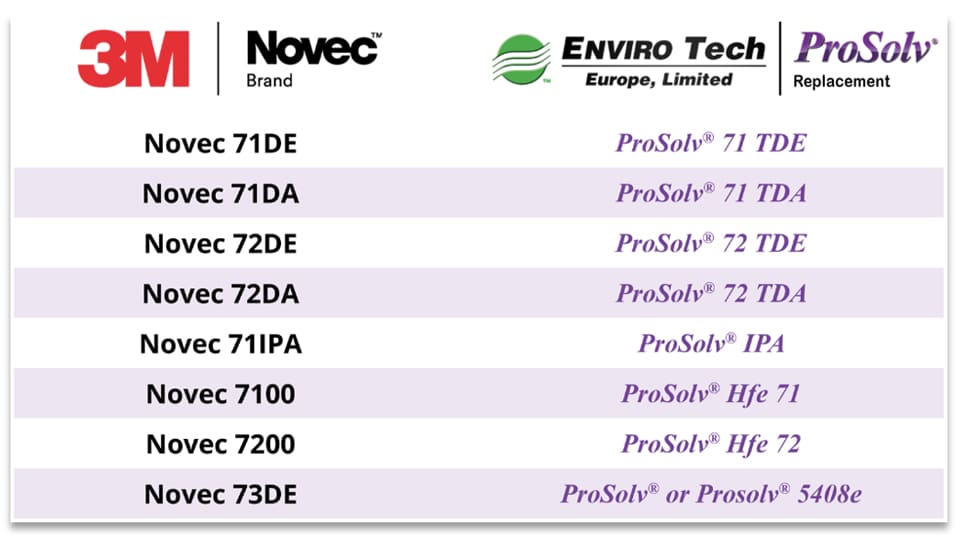

EnviroTech Europe offers a range of direct replacements for the discontinued 3M™ Novec™ products, providing companies with a seamless transition without compromising performance, safety, cost, or compliance. Our ProSolv® Direct Replacements have been specifically developed to be exact chemical replacements for all Novec™ fluids. These high-performance solvents are designed to match all the properties and specification of the relevant Novec™ solvent, ensuring an easy transition with minimal process modifications

Benefits of switching to ProSolv® Direct Replacements range

Seamless integration: Compatible with existing vapour degreasing and precision cleaning systems. Superior cleaning performance which effectively removes oils, greases, and particulate contaminants.

Environmentally responsible: Low GWP, non-ozone depleting, REACH-compliant, safe and sustainable, non-flammable and designed for long-term availability.

Support: Our technical staff provide free-of-charge consultation visits and product trials to help guide your transition away from 3M™ Novec™ engineered fluids.

ACT NOW TO SECURE YOUR SUPPLY.

Businesses must act fast to maintain operational efficiency. EnviroTech Europe can provide a full assessment of your current cleaning process to put in a plan to help ensure a seamless transition. We have already successfully transitioned many Novec™ users globally to our ProSolv® Direct Replacements range, ensuring reliability and compliance for years to come.

NEXT GENERATION, PFAS-FREE SOLVENT CLEANING SOLUTIONS.

EnviroTech Europe also supplies ProSolv®5408e, a PFAS-Free high performance vapour degreasing solvent – offering next-generation, multi-purpose solvent cleaning with zero ODP (Ozone Depletion Potential) and near zero GWP (Global Warming Potential). ProSolv®5408e is tested to a number of industry standards including ASTM D3828, ASTM E918, Stock Loss ARP1755B and ASTM F945-1.

FURTHER INFORMATION

Please visit our website www.envirotech-europe.com/replacements-for-3M-Novec-engineered-fluids for more information about replacing 3M™ Novec™ solvents.

Visit www.envirotech-europe.com/prosolv5408e for information about our next-generation PFAS-free vapour degreasing solvent cleaners. For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

Share this page:

Related Posts

Co-solvents for electronics cleaning

Co-solvent cleaning enhances the solubility of contaminants and improves efficiency and performance

What is co-solvent cleaning?

Co-solvent cleaning is a powerful and versatile vapour degreasing process that uses a combination of two solvents to clean a variety of substrates. Particularly useful in electronics cleaning, this process is a safe and efficient way to remove organic and mineral residues from solder fluxes and pastes.

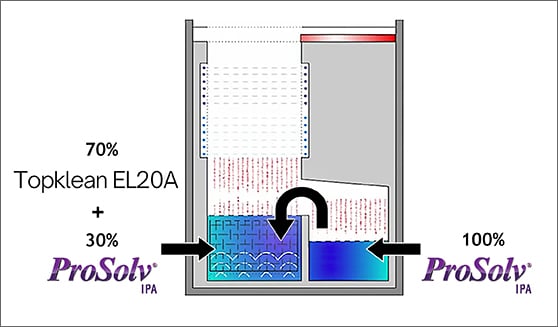

The co-solvent cleaning process uses a mixture of the solvating agent (Topklean EL20A) and a rinsing agent (ProSolv®IPA) in the first cleaning stage, followed by just the rinsing agent in the second stage. Excellent for applications where solubility, material compatibility, sustainability and regulatory compliance are important. Perfect for cleaning circuit boards, semiconductors, avionics, and optical instruments. Co-solvents will help to dissolve contaminants that a single solvent alone may struggle to remove by modifying the overall polarity, viscosity, and evaporation rate of the cleaning solution.

High quality and versatile co-solvents from EnviroTech Europe

Topklean EL20A is designed to clean solder paste deposits, fluxes and other residues in the production of PCBs, offering excellent cleaning capacity and a very low environmental impact. Designed for use in a co-solvent process to remove residues and leave the surface free of organic and inorganic deposits.

ProSolv®IPA is an environmentally friendly azeotropic solvent cleaner – Ideal for removing adhesives, buffing compounds, drawing oils, fluxes and pastes, greases, hydraulic oils, lapping compounds, resins, inks, silicone oils, and waxes, ensuring thorough and efficient cleaning.

Non-flammable and stable throughout the refluxing of the system, it is ideal for applications such as light surface contamination cleaning, fingerprint removal, tank flushing, dust particle cleaning (metallic, glass or plastic) and precision rinsing. Use Topklean EL20A in conjunction with ProSolv®IPA to enhance cleaning and drying performance.

The co-solvent cleaning process for electronics cleaning

Increasing demand for miniaturized electronic assemblies has led to greater challenges in the parts cleaning process, and manufacturers need to solder with greater precision to avoid problems like corrosion and short circuiting. Co-solvent cleaning enhances the solubility of contaminants, improves efficiency and performance, and helps remove difficult soils which often require high temperatures. Perfect for cleaning small components, high density PCB’s or boards populated with very low stand-off components.

A Simple 3-Step Process

Cleaning: Parts are immersed in the boiling sump, which contains a blend of Topklean EL20A and ProSolv®IPA. The low viscosity of the mixture allows for the cleaning of small components and high-density PCB’s.

Rinsing: Parts are rinsed in the clean sump of the vapour degreasing tank, which is filled with ProSolv®IPA. With the co-solvent process,

re-deposition of soils is minimized.

Final stage: Components are moved into the vapour zone for drying, without the need for expensive high-temperature ovens. The entire process is done automatically and under a sealed lid. EnviroTech Europe also supplies vapour degreasing equipment like the Solvac S2 which is perfect for co-solvent cleaning.

CO-SOLVENT CLEANER BENEFITS

- Enhanced solubility

- Improved cleaning efficiency

- Reduced toxicity

- Reduced environmental Impact

- Lower VOC emissions

- Controlled evaporation rates

- Material compatibility

- Low energy / cost efficient

- Regulatory compliance

INDUSTRY APPLICATIONS

- Aerospace and avionics

- Electronics

- Medical device cleaning

- Machining

- Automotive parts and engine cleaning

- Paint and coating removal

- Pharmaceutical and laboratory cleaning

FURTHER INFORMATION

Please visit https://www.envirotech-europe.com/vapour-degreasing-solvents/co-solvent-cleaners/ for more information.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

EnviroTech Europe | 2025 Brochure

Advanced solutions for solvent cleaning, vapour degreasing, corrosion protection and metal surface cleaning

EnviroTech Europe supply approved vapour degreasing solvents, solvent cleaners and corrosion protection products. We offer a range of formulations tailored to your industry, which are cost effective, energy efficient, safe for operators and the environment.

We are pleased to introduce our range of products in our 2025 products brochure.

FURTHER INFORMATION

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Latest News

VIDEO: SuperCORR A Is The Ultimate Defence Against Corrosion

Corrosion Protection - The Ultimate Defence

Super CORR A is an advanced corrosion protection spray that was originally designed to prevent electrical and electronic components from systems failures caused by corrosion. Developed for the U.S. Air Force and within strict safety specifications (complies with MIL-DTL-87177B), it has been the proven standard for avionic corrosion protection within MROs (maintenance, repair and operations) and OEMs (overhaul and original equipment manufacturers).

Super CORR A‘s unique ability to displace water and provide a performance enhancing level of corrosion protection has led to it being used in many other applications and industries worldwide.

Super CORR A works particularly well in harsh environments and where corrosive gases such as salt laden air or hydrogen sulphide are present. It is unexcelled in preventing deterioration and contamination of metal surfaces and it is used in many applications worldwide, including industrial manufacturing, rail and road transport, oil and gas industries, wastewater treatment plants, electrical power facilities, paper and pulp mills, marine and military industries.

Advanced corrosion protection for a range of industries and applications

Super CORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors providing a superior lubrication coefficient and protection against moisture, wear, general and fretting corrosion, static electricity, corona, and other electro migration problems. The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive.

The use of Super CORR A for corrosion protection can not only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace the damaged equipment or component that failed because of corrosion. It is very effective at preventing corrosion of electronic and electrical equipment in demanding work environments.

Super CORR A is a “self-healing” ultra-thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack, is not a wax or oil-based product and is formulated without sulphates, chlorides or halogens.

Super CORR A also inhibits corrosion caused by exposure to both fresh and salt water moisture as well as the corrosive vapours from Sulphur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulphide (H2S), Ammonia (NH3), and Chlorine (CL12) based gases found in the aircraft industry.

Super CORR A is packaged in aerosol cans making application to component parts easy for engineering crews in difficult locations and conditions. Unpainted mild steel will not rust on exterior surfaces directly exposed to sea water environments for at least 6 months, protecting electrical connectors, switches, chains, drive shafts from corrosion while maintaining lubrication on moving surfaces.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

- Non-flammable.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

VIDEO: Choosing the correct vapour degreasing equipment to suit your cleaning process

Choosing the correct vapour degreasing equipment to suit your cleaning process

Choosing the correct vapour degreasing equipment is crucial for ensuring the efficiency, safety, and effectiveness of your cleaning process. Envirotech Europe offer a full range of the latest ultrasonic vapour degreasing equipment, using the most up-to-date technology. We offer customizable systems with options such as semi or full automation, including in/out roller beds, basket rotation or basket agitation.

Several key considerations need to be made to ensure your new equipment meets your specific cleaning needs such as efficiency requirements, and regulatory compliance. Here are the main factors to consider:

Types of Contaminants and Parts:

Identify the types of contaminants (oil, grease, flux, particulates) that need to be removed. Make sure the degreasing solvent and process are compatible with the materials of the parts being cleaned. Evaluate the complexity and size of the parts. Complex geometries may require more sophisticated equipment to ensure thorough cleaning. Components with blind holes may require rotation on the equipment.

Vapour degreasing solvents such as ProSolv® / ProSolv®5408e from Envirotech Europe feature high solvency power and have the ability to remove common contaminates. These solvents feature low surface tension and ensure the highest levels of cleanliness for even the most complex of components.

Production Volume and Throughput:

Choose between batch processing units for smaller volumes or continuous processing units for high-volume operations. Consider the cycle time required to clean each batch or part and make sure this aligns with your production schedule. Vapour degreasing equipment provided by Envirotech Europe will achieve excellent levels of cleanliness in a matter of minutes, leaving components clean, rinsed and dried with no residue.

Solvent Selection and Regulations:

Check the solvent is compatible with both components and equipment. Consider solvents with appropriate boiling points, cleaning efficiency, and drying times for your specific application. Make sure the solvent complies with local and international environmental and safety regulations.

In December 2022 3M™ announced plans to stop producing per- and polyfluoroalkyl substances (PFAS)

substances in its product line by the end of 2025. This phase-out affects the 3M™ Novec™ range of engineered fluids. Envirotech Europe offers the very latest vapour degreasing solvent chemistries helping to future-proof your process. This includes the ProSolv® range of direct replacements for 3M™ Novec™ engineered fluids. If your organisation is using 3M™ Novec™ fluids, contact Envirotech Europe to discuss suitable replacements.

ProSolv®5408e offers excellent levels of cleanliness whilst meeting health, safety and environmental considerations. It is a PFAS-free, high performance vapour degreasing solvent produced in the UK, and guarantees the highest levels of cleanliness. Compatible with most common alloys, ProSolv®5408e features high solvency power, low surface tension, is non-flammable, low risk phrase, Low GWP (global warming potential of 1) and zero ODP (ozone depletion potential).

System Design and Features:

Open-Top vs. Enclosed Systems: Open-top systems are simpler and less expensive but may have higher emissions. Enclosed systems offer better emission control and safety features. Determine if you need manual, semi-automated, or fully automated systems based on labour availability and consistency requirements. Ensure the equipment can accommodate the largest parts you need to clean and has the capacity for your production volume.

Cost and Return on Investment (ROI):

Consider the purchase cost of the equipment and factor in the cost of solvents, energy consumption, maintenance, and labour. Evaluate potential savings from reduced solvent usage, improved cleaning efficiency, and lower emissions.

Safety and Compliance:

Make sure the equipment has adequate safety features to protect workers from exposure to harmful solvents. Verify that the equipment and process comply with relevant health, safety, and environmental regulations. Ensure the equipment has effective fume extraction to protect workers and comply with regulations. Equipment with advanced control systems can reduce the risk of human error and improve safety. For flammable solvents, make sure the equipment is equipped with appropriate fire suppression systems. Compliance with occupational health and safety regulations is essential to protect workers.

Energy Efficiency:

Look for equipment with efficient heating and cooling systems to minimize energy usage and reduce solvent consumption. Equipment with efficient solvent recovery and recycling can reduce operating costs and environmental impact. Envirotech Europe offers the latest low boiling solvents massively reducing energy consumption usage.

Supplier Support and Service:

Choose a reputable supplier with experience in vapour degreasing. EnviroTech Europe has over thirty years of experience in the vapour degreasing and solvent cleaning industry. Ensure the supplier offers good technical support, training, and maintenance services. Check if the supplier can customize the equipment to meet your specific needs. Envirotech Europe offers technical support and advice on your equipment and solvent compatibility.

Testing, Validation and other Considerations:

Before committing to a purchase, conduct pilot testing with sample parts to ensure the equipment meets your cleaning requirements. Envirotech Europe offer free testing and validation trials. Ensure the equipment can consistently meet the cleanliness standards required for your specific application. Look for energy-efficient equipment designs to reduce operational costs. Make sure the system has effective emission control features, such as refrigerated coils or carbon absorption systems. Choose equipment that is easy to maintain and service to minimize downtime.

Conclusion:

To select the correct vapour degreasing equipment, carefully evaluate your cleaning requirements, production needs, solvent compatibility, safety, and regulatory considerations. Collaborate with reputable suppliers to ensure you choose a system that provides optimal performance and compliance with all relevant standards.

Envirotech Europe supply a full portfolio of vapour degreasing equipment as well as the latest precision cleaning chemistries for both solvent and aqueous cleaning, including free qualification trials and free on-site technical visits to advise on your specific circumstances. Please visit our website to view specific vapour degreasing equipment and solvent cleaning solutions.

FURTHER INFORMATION

Please visit www.envirotech-europe.com/vapour-degreasing-equipment for more information.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

VIDEO: Replacements for 3M™ Novec™ Engineered Fluids

ARE YOU AFFECTED BY THE PHASE-OUT OF 3M™ NOVEC™ ENGINEERED FLUIDS?

At Envirotech Europe we can offer replacements with our ProSolv® range for all 3M™ Novec™ solvent cleaning fluids. We understand the uniqueness of every precision cleaning application and provide free on-site visits, technical support and cleaning trials when required.

We can provide a full assessment of your current precision cleaning process to put in a plan to help ensure a seamless transition.

Future-proof your cleaning process with our new ProSolv® range additions.

We have added several cost effective and efficient precision cleaning process formulations to our range of ProSolv® vapour degreasing solvents, offering an immediate drop in replacements for the 3M™ Novec™ engineered fluids.

FURTHER INFORMATION

Please visit https://www.envirotech-europe.com/vapour-degreasing-solvents/replace-3m-novec-engineered-fluids/ for more information.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

The importance of corrosion protection in the aircraft and aviation industry

Aircraft corrosion protection - The importance of corrosion protection in the aircraft and aviation industry

Aircraft corrosion protection is crucial for several reasons, encompassing safety, economic efficiency, and regulatory compliance. Here are the key aspects highlighting its importance:

Safety:

Structural Integrity – Corrosion can weaken the structural components of an aircraft, leading to potential failures. This compromises the safety of the aircraft, posing risks to both passengers and crew. Component Reliability – Corrosion can affect critical components such as landing gear, control surfaces, and engines, potentially leading to malfunctions or failures during flight.

Economic Efficiency:

Maintenance Costs – Regular and effective corrosion protection reduces the frequency and severity of repairs needed. This minimizes downtime and maintenance costs. Longevity of Aircraft – Proper corrosion protection extends the service life of an aircraft, delaying the need for costly replacements.

Performance:

Fuel Efficiency – Corrosion can increase the drag on an aircraft by affecting its aerodynamic surfaces, leading to higher fuel consumption. Weight Management – Corroded components might need to be reinforced or replaced with heavier parts, impacting the aircraft’s weight and balance.

Regulatory Compliance:

Adherence to Standards – Aviation authorities such as the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency) have strict regulations regarding aircraft maintenance and airworthiness, including corrosion control measures. Inspection Requirements – Regular inspections mandated by regulatory bodies often focus on detecting and addressing corrosion, ensuring that aircraft meet the necessary safety standards.

Environmental Considerations:

Material Conservation – Effective corrosion protection reduces the need for frequent replacement of parts, conserving materials and reducing waste. Chemical Use – Proper corrosion management minimizes the use of harsh chemicals required for treating advanced stages of corrosion, benefiting environmental sustainability.

Operational Readiness:

Reliability – Corrosion protection ensures that aircraft remain in optimal condition, ready for operation without unexpected delays due to maintenance issues. Fleet Management – For airlines, maintaining a corrosion-free fleet ensures better scheduling and utilization of aircraft, enhancing overall operational efficiency.

Corrosion Protection Solutions for Aircraft:

Protective coatings and paints act as barriers between the aircraft’s metal surfaces and the environment. One such coating is Super CORR A advanced lubricant and corrosion inhibiting compound, based on approved synthetic materials, to provide quality solutions to a diverse range of lubrication and corrosion problems. A unique and proprietary formulation with long-lasting, anti-corrosion inhibitors providing a superior lubrication coefficient and protection against moisture, wear, general and fretting corrosion, static electricity, corona, and other electro migration problems.

Conclusion:

The importance of aircraft corrosion protection cannot be overstated. It is a fundamental aspect of aircraft maintenance that ensures safety, economic viability, regulatory compliance, and environmental sustainability. Effective corrosion control measures are integral to maintaining the integrity and performance of aircraft, ultimately supporting the reliability and efficiency of the aviation industry.

SuperCORR A Specialist barrier film corrosion protection for aircraft

EnviroTech Europe supplies advanced corrosion protection products, based on approved synthetic materials, to provide quality solutions to a diverse range of lubrication and corrosion problems.

Super CORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors providing a superior lubrication coefficient and protection against moisture, wear, general and fretting corrosion, static electricity, corona, and other electro migration problems. The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive.

The use of Super CORR A for corrosion protection can not only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace the damaged equipment or component that failed because of corrosion.

Super CORR A is a non-flammable “self-healing” ultra-thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack, is not a wax or oil-based product and is formulated without sulphates, chlorides or halogens.

Super CORR A also inhibits corrosion caused by exposure to both fresh and salt water moisture as well as the corrosive vapours from Sulphur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulphide (H2S), Ammonia (NH3), and Chlorine (CL12) based gases found in the aircraft industry.

Super CORR A is packaged in aerosol cans making application to component parts easy for engineering crews in difficult locations and conditions. Unpainted mild steel will not rust on exterior surfaces directly exposed to sea water environments for at least 6 months, protecting electrical connectors, switches, chains, drive shafts from corrosion while maintaining lubrication on moving surfaces.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

HISTORY

Super CORR A was originally developed for the U.S. Air Force to comply with military specifications and to prevent electrical and electronic components from systems failures caused by corrosion. It became the industry standard for avionic corrosion protection within MROs (maintenance, repair and operations) and OEMs (overhaul and original equipment manufacturers). It’s unique ability to displace water and provide a performance enhancing level of corrosion protection has led to it being used in many other applications and industries worldwide.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Alternatives to 3M™ Novec™ Engineered Fluids

A range of premium quality drop-in alternatives to 3M™ Novec™ Engineered Fluids from EnviroTech Europe

In December 2022, 3M™ announced their plans to stop producing per- and polyfluoroalkyl substances (PFAS) in its product line by the end of 2025.

This phase-out affects the following 3M™ product lines:

3M™ Novec™ Engineered Fluids

3M™ Fluorinert™ Electronic Liquids

ARE YOU AFFECTED BY THE PHASE-OUT OF 3M™ NOVEC™ ENGINEERED FLUIDS?

EnviroTech Europe now offers alternatives to all 3M™ Novec™ solvent cleaning fluids with our ProSolv® range. We understand the uniqueness of every precision cleaning application and provide free on-site visits, technical support and cleaning trials when required.

We can provide a full assessment of your current precision cleaning process to put in a plan to help ensure a seamless transition.

FUTURE-PROOF YOUR CLEANING PROCESS WITH OUR ProSolv® RANGE OF ALTERNATIVES

We have added several cost effective and efficient precision cleaning process formulations to our range of ProSolv® vapour degreasing solvents, offering immediate drop-in alternatives to 3M™ Novec™ engineered fluids.

WHY ACT NOW?

The 3M™ Novec™ range of engineered fluids could soon potentially face shortages and 3M™ distributors world-wide could be struggling to fulfil orders as we get closer to 2025. Some of the 3M™ Novec™ grades will start to become unavailable, others with long lead times and inflated prices as stocks diminish. Envirotech Europe provides chemically exact drop-in alternatives to 3M™ Novec™ engineered fluids, under our ProSolv® range. We will continue to supply this range well after 3M™ leave the market, providing you with peace of mind and control over your supply. Our products are supported by technical experts in the precision cleaning sector we offer our full guidance to keep your precision cleaning process running smoothly.

EnviroTech Europe recommends that customers start the transition as soon as possible to avoid any potential disruption. As well as supplying 3M™ Novec™ drop-in alternatives, Envirotech Europe supply a new generation of PFAS-free cleaning chemistries to future proof your process for many years to come, such as our world-renowned ProSolv®5408e vapour degreasing solvent, which is already widely used across an array of sectors. Envirotech Europe follows up closely on all regulations around the world and are able anticipate well in advance on any changes, to keep you one step ahead. We provide free of charge consultation visits to help your site transition from the 3M™ Novec™ grades. Book your visit now and let us help you keep your critical cleaning process running smoothly with the UK’s leading supplier of precision cleaning chemistries.

FURTHER INFORMATION

Please visit www.envirotech-europe.com/vapour-degreasing-solvents/replace-3m-novec-engineered-fluids/

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Next-generation PFAS-Free solvent cleaners – Championing Change Through Innovation

Next-generation PFAS-Free solvent cleaners – Championing Change through innovation

Vapour degreasing, with or with-out ultrasonics, is the oldest, simplest and most effective solvent degreasing and metal cleaning process used today. It has until recently been subject to little change since it was first invented in the early part of the last century. In the UK, Europe, United States and other advanced economies, increasingly stringent legislation has been put in place to control emissions of VOCs (Volatile Organic Compounds), Global Warming Compounds, Ozone Depleting Compounds and those compounds associated with human health concerns such as PFAS chemicals. This has led to new formulations being developed for solvent cleaners.

The vapour cleaning process still gives the highest levels of economical cleaning with minimum energy usage, low footprint on the factory floor, safety for the operator, and high production rates, with low solvent usage and low environmental impact. With the new generation of sealed cleaning machines its future as the process of choice is assured. Recent regulations on the control of PFAS (Per- and polyfluoroalkyl substances) have resulted in the clamping down on solvents with a high GWP (Global Warming Potential).

Envirotech Europe supplies a next generation vapour degreasing solvent formulation called ProSolv®5408e, with zero Ozone Depletion Potential (ODP) and a Global Warming Potential (GWP) of less than 1, making it safe for operators and kind on the environment. For anyone using solvents with high HFC / HFE such as the soon to be phased out 3M™ Novec™ range, we have direct replacements available.

Advanced vapour degreasing solvent with zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP)

ProSolv®5408e has been developed to provide superior critical cleaning performance, suitable for many different industries. High Solvency (KB Value 98) for removal of organic residue and oils, compatible with organic and synthetic oils and most plastics and metals.

ProSolv®5408e ticks all the boxes and is the perfect profile for a modern degreasing solvent. Exceptionally low surface tension to penetrate micron sized holes and close contact surfaces. Sustainable and secure for the future. Non-carcinogenic, low boiling point, economical with energy with low solvent losses, faster production, reduced costs, easy handling.

ProSolv®5408e can be used in most solvent cleaning systems, vapour degreasing or multi tank immersion / systems using ultrasonics. Also suitable for flushing of complex mechanical and electronic components with blind holes and channels.

ProSolv®5408e has a unique formulation making it PFAS-free, ensuring that your process falls within environmental legislation considerations.

SAFE FOR USERS AND THE ENVIRONMENT

- PFAS Exempt

- GWP of less than 1

- Non-hazardous for transportation.

- Non-flammable (No Flash Point).

- Not classified as a carcinogen.

- RoHS compliant.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/prosolv5408e for information about other uses and applications for ProSolv®5408e.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Electrical corrosion protection – Prevent hydrogen sulphide corrosion in electrical and electronic equipment

Electrical corrosion protection - Prevent hydrogen sulphide corrosion in electrical and electronic equipment

Corrosion in its many forms, costs both private and public sectors hundreds of billions a year to repair or replace electrical, electronics, or avionic components because of failures caused by corrosion. Lost productivity and revenue caused by plant and equipment corrosion is a serious matter. While all metals corrode, due to a number of different factors, there is no simple or single solution to the overall corrosion problem. However there are some very cost effective and proven ways to prevent corrosion and failures caused by corrosion and thereby reducing or eliminating associated costs and increasing safety which should be foremost in the mind set of any preventative maintenance programme.

Electrical and electronic equipment and components that are used in adverse environments, e.g. the oil and gas industry, waste-water treatment plants and the pulp and paper industry, where corrosive gases such as hydrogen sulphide can be found, cause severe corrosion and the rapid deterioration of the electronic components and equipment including connectors and switches used in these and other work environments. Preventing hydrogen sulphide (H2S) corrosion in electrical and electronic equipment involves a combination of preventive measures and material selection. Here are some steps to mitigate H2S corrosion:

Protective Coatings:

An essential corrosion preventative measure is to apply coatings to vulnerable components. One such coating is Super CORR A advanced lubricant and corrosion inhibiting compound. It will help prevent H2S corrosion in electrical and electronic equipment, ensuring their longevity and reliability in environments where H2S exposure is a concern.

Material Selection:

Choose materials that are resistant to H2S corrosion. For example, stainless steel, nickel alloys, and certain plastics are less susceptible to corrosion by H2S compared to carbon steel.

Enclosures, Sealing and Ventilation:

Seal electrical and electronic equipment and cables in airtight enclosures to prevent H2S exposure. Ensure these enclosures are made from corrosion-resistant materials. Implement ventilation systems to reduce the concentration of H2S in the equipment’s environment.

Monitoring and maintenance::

Regularly monitor H2S levels in the environment where the equipment is installed. Install gas detectors to provide early warnings of increased H2S concentrations. Perform regular maintenance checks on equipment to detect any signs of corrosion. Replace any corroded components promptly.

Design Considerations:

Consider the design of the equipment and its surroundings to minimize the likelihood of H2S exposure. For example, elevating equipment above potential H2S sources can reduce corrosion risk.

Education and Training:

Provide education and training to personnel working with the equipment on the risks of H2S corrosion and the importance of preventive measures.

Emergency Response Plan:

Develop an emergency response plan in case of H2S exposure or equipment failure due to corrosion. This plan should include procedures for evacuating personnel and shutting down equipment safely.

SuperCORR A Specialist Barrier Film Corrosion Protection

EnviroTech Europe supplies advanced corrosion protection products, based on approved synthetic materials, to provide quality solutions to a diverse range of lubrication and corrosion problems.

Super CORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors providing a superior lubrication coefficient and protection against moisture, wear, general and fretting corrosion, static electricity, corona, and other electro migration problems. The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive.

The use of Super CORR A for corrosion protection can not only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace the damaged equipment or component that failed because of corrosion.

Super CORR A is a proven and cost-effective way to prevent or inhibit corrosion from destroying electronics and electrical components. It was specifically designed to lubricate and prevent corrosion in electrical fittings and connectors; electrical and avionic harness assemblies and connectors; electrical and electronic switches; close tolerance and dissimilar metal components; lighting connectors and sockets. A unique non-flammable “self-healing” ultra-thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack, is not a wax or oil-based product and is formulated without sulphates, chlorides or halogens.

Super CORR A also inhibits corrosion caused by exposure to both fresh and salt water moisture as well as the corrosive vapours from Sulphur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulphide (H2S), Ammonia (NH3), and Chlorine (CL12) based gases found in waste water and sewer treatment plants, pulp and paper mills and plants, chemical and petroleum plants, maritime industry, aircraft/airline industry, military equipment including ships, aircraft, and rolling stock, auto industry, farming and agriculture industry, and the list goes on.

Super CORR A is packaged in aerosol cans making application to component parts easy for engineering crews in difficult locations and conditions. Unpainted mild steel will not rust on exterior surfaces directly exposed to sea water environments for at least 6 months, protecting electrical connectors, switches, chains, drive shafts from corrosion while maintaining lubrication on moving surfaces.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

HISTORY

Super CORR A was originally developed for the U.S. Air Force to comply with military specifications and to prevent electrical and electronic components from systems failures caused by corrosion. It became the industry standard for avionic corrosion protection within MROs (maintenance, repair and operations) and OEMs (overhaul and original equipment manufacturers). It’s unique ability to displace water and provide a performance enhancing level of corrosion protection has led to it being used in many other applications and industries worldwide.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Replacements for 3M™ Novec™ Solvents from EnviroTech Europe

A range of drop-in replacements for 3M™ Novec™ solvents

In December 2022, 3M™ announced their plans to stop producing per- and polyfluoroalkyl substances (PFAS) in its product line by the end of 2025. This phase-out affects the following 3M™ product lines:

3M™ Novec™ Engineered Fluids

3M™ Fluorinert™ Electronic Liquids

ARE YOU AFFECTED BY THE PHASE-OUT OF 3M™ NOVEC™ ENGINEERED FLUIDS?

At Envirotech Europe we can offer replacements with our ProSolv® range for all 3M™ Novec™ solvent cleaning fluids. We understand the uniqueness of every precision cleaning application and provide free on-site visits, technical support and cleaning trials when required.

We can provide a full assessment of your current precision cleaning process to put in a plan to help ensure a seamless transition.

Future-proof your cleaning process with our new ProSolv® range additions.

We have added several cost effective and efficient precision cleaning process formulations to our range of ProSolv® vapour degreasing solvents, offering an immediate drop in replacements for the 3M™ Novec™ engineered fluids.

Introducing ProSolv®5408e, a next generation PFAS free fluorinated solvent offering low GWP and zero ODP.

ProSolv® 5408e is a next generation PFAS free fluorinated solvent offering low Global Warming Potential (GWP) & zero Ozone Depletion Potential (ODP). A general multi-purpose vapour degreasing cleaning solvent that can act as an immediate drop-in replacement for most of the 3M™ Novec™ engineering fluids. We can also deliver an exact formulation replacement of your current solvent should that be your requirements.

EnviroTech Europe have many years of experience and our experts are available to guide you through your solvent cleaner changeover procedures or to advise on equipment. We have extensive partnerships with equipment manufacturers through our global distributors and can provide information and advice on solvents and solvent systems.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/prosolv5408e for information about other uses and applications for ProSolv® 5408e.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts