Latest Articles

General purpose industrial cleaning solvents

Clarea® general purpose industrial cleaning solvents for safe removal of dirt, oil, grease and other contaminants

Hand or bath cleaning solvents are used in many industries to remove dirt, oil, grease, or other contaminants from machined and fabricated metal, plastic and composite surfaces. Due considerationmust be given to the effects on users and the environment. Cleaning solvents must be highly refined and leave no residues on drying. They have to be very effective in removal of oils and soils without causing damage or corrosion of the parts or components being cleaned.

Pre-used parts or assemblies from the transportation, aerospace or manufacturing equipment sectors are often very heavily contaminated when removed from service but must be free of all contaminants before handling to disassemble prior to refurbishing and rebuilding. Much of this work will be manual and the considerations for the safety of operators is paramount.

Growing concerns regarding environmental and health hazards of the commonly used chlorinated solvents for industrial degreasing and cleaning has led to the formulation of the Clarea® range of industrial cleaning solvents by EnviroTech Europe.

An environmentally safe range of hand and bath solvent cleaners

Clarea® industrial solvent cleaners are compatible with all metals, composites and most plastics used to remove dirt, oil, grease, or other contaminants from surfaces without causing harm or leavingresidue. They are used as immersion cleaners for component cleaning in manufacturing andengineering industries and as wipe cleaners for large surface areas prior to painting or powder coating. Clarea® cleaning solvents are aliphatic hydrocarbon-based degreasing solvents with specified flash points. They are non-carcinogenic, low odour, fast drying and cause no ozone depletion. They leave minimal residues on drying surfaces and contain no halogens such as chlorine or fluorine.

Clarea HC40 is a degreasing solvent with a flash point of 40°C. It is suitable for brush and hand wiping processes.

Clarea HC62 is a degreasing solvent with a flash point over 60°C. It is suitable for spray or immersion cleaning, or hand wipe applications when used externally.

Clarea HC96 is a degreasing solvent with a flash point of 96°C. It is suitable for spray or immersion cleaning.

Product Benefits

● Versatile and cost-effective solutions for all your industrial cleaning.

● Minimal odour and low toxicity for operators.

● Multipurpose uses can reduce the inventory of cleaning fluids.

● Flexible uses – evaporation rates suitable for hand wipe, spray, or immersion tank cleaning.

● Contains no chlorine, other halogens or stabilisers.

● Compatible with all metals and composites and most plastics.

● Excellent pre-cleaner for paint or powder coatings.

● Safe, reliable, environmentally friendly cleaning.

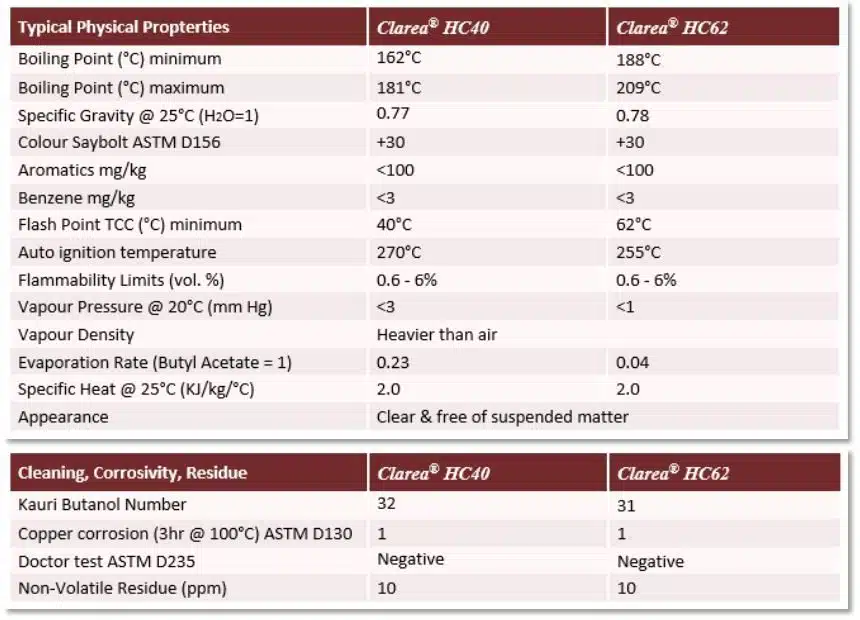

Solvent Properties

Packaging

Clarea® HC40 and Clarea® HC62 is available in the following container sizes and weights:

205 litre drums, 25 litre cans, 5 litre cans. Clarea® HC96 is available in 15kg cans and 165kg drums.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Advanced corrosion protection for automation and engineering industries

SuperCORR A – Advanced corrosion protection for automation and engineering industries

Corrosion is serious problem for industry and governments worldwide

Corrosion, in its many forms, costs both private and public sectors vast amounts of money to repair or replace mechanical, electrical and electronics components. While all metals corrode, due to various reasons, there is no simple or single solution to the overall corrosion problem. However, there are some very cost effective and proven ways to prevent corrosion and failures caused by corrosion, thereby reducing or eliminating associated costs and increasing safety, which should be of foremost importance in the mind set of any preventative maintenance programme manager.

Corrosion is an increasingly serious and costly problem that can lead to equipment failures which range from being an annoyance to being catastrophic. Failures caused by corrosion could and do lead to a direct failure of a component which could affect the entire system and can not only be very expensive in terms of down time to repair or replace but can also prove to be very costly in loss of productivity, and possibly the loss of human life.

The financial cost of corrosion accounts for between 3% to 6% of a country’s GNP [1] and a 2016 study by NACE International concluded that the annual global cost of corrosion amounts to USD 2.5 trillion [2]. These costs increase each year.

A vast amount of the annual cost of corrosion can be saved by using corrosion inhibitor products such as Super CORR A which was specifically designed to lubricate and prevent corrosion in electrical fittings and connectors, electrical harness assemblies and connectors, electrical and electronic switches, close tolerance and dissimilar metal components, lighting connectors and sockets. It is a non-flammable “self-healing” ultra-thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack. is not a wax or oil-based product and is formulated without sulphates, chlorides or halogens.

Super CORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors providing a superior lubrication coefficient and protection against moisture, wear, general and fretting corrosion, static electricity, corona, and other electro migration problems. The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive.

Manufactured and supplied by EnviroTech Europe Ltd, it is unexcelled in preventing failures of electrical systems and electronic equipment caused by corrosion as well as preventing the corrosion of metal components surfaces. Use Super CORR A to protect connectors, electrical systems and switches and mechanical controls during servicing. It’s ability to displace water from exposed contacts can ensure reliable operation in extreme conditions, all from one small aerosol can.

CASE STUDIES

Prevent hydrogen sulphide corrosion in electrical and electronic equipment

Electrical and electronic equipment used in adverse work environments (e.g., the oil and gas, water treatment, pulp and paper industries) where corrosive gases such as hydrogen sulphide are found, can be particularly vulnerable to corrosion and lead to the rapid deterioration of the electronic components including mechanical controls, connectors and switches. Super CORR A inhibits corrosion caused by exposure to both fresh and salt water moisture as well as the corrosive vapours from Sulphur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulphide (H2S), Ammonia (NH3), and Chlorine (CL12) based gases found in waste water and sewer treatment plants, pulp and paper mills and plants, chemical and petroleum plants, maritime industry, aircraft/airline industry, military equipment including ships, aircraft, and rolling stock, auto industry, farming and agriculture industry, and the list goes on.

HFC-227ea gaseous fire suppression for electronic equipment.

When activated in a fire situation HFC-227ea will decompose to produce Hydrogen Fluoride. This is a real and ongoing concern. Why? Because Hydrogen Fluoride causes major corrosion problems for electronics and connectors. You may save your equipment but for how long?

To prevent corrosion caused by Hydrogen Fluoride, as well as other chemicals, acids, salts, and water which can be deposited during the activation of fire suppression systems or rapid humidity changes, all the electrical and electronic hardware, boards and connectors should be sprayed or coated with Super CORR A. It will protect and prevent damage to the electronics or avionics caused by exposure to the Hydrogen Fluoride produced as a by-product during the fire.

Fretting corrosion on gas turbine connectors

LP Gas Turbines are used throughout the world by extraction industries and manufacturing plants in remote and hostile locations for essential power production. Dusty and wet environments in deserts, mines, grinding mills, pulp and paper mills and on land or sea drilling rigs for gas and oil production. Turbines powering aircraft services while stationary connect and disconnect many times a day in extreme conditions. These applications and locations test connector sealing continuously allowing dust or water to penetrate. This with the flexing of the connecting cables allows sufficient movement between the metal surfaces of the connecting pins to produce fretting corrosion which reduces, interrupts or produces failures in supply. Regular maintenance of electrical connectors is essential to be certain of uninterrupted supply.

Containing extremely long-lasting, proprietary anti-corrosive inhibitors Super CORR A provides a superior lubrication coefficient and protects components against moisture, wear, general and fretting corrosion, surface static electricity, corona, and other electromigration problems.

Avionic corrosion protection

Super CORR A extends the working life of avionic harness assemblies, electrical systems and other critical items in aircraft maintenance by preventing the deterioration and/or failure caused by corrosion and can significantly reduce downtime, operating and maintenance costs as well as enhance safety. It has as undergone extensive testing by Battelle Labs as well as the U.S. Air Force and meets MIL-DTL-87177B (revised MIL-L-87177A) specification.

Super CORR A is used by NATO (NATO NSN 8030-99-226-6966) to protect avionic electrical switches, sockets, connectors and components from corrosion in both the military and civilian aircraft. It is the global industry standard for electrical corrosion protection, for in service maintenance by both military and commercial aircraft major repair and overhaul (MRO) facilities.

Sea Spray exposure

Most people associate corrosion control with rust, which only happens in things made of ferrous metals such as steel girders, ships, iron pipes, steel reinforcement rods, and steel tanks and is the reason metals deteriorate and fail. Ferrous and non-ferrous metals corrode on contact with both fresh and saltwater as well as water vapour. They will also corrode when they come into contact with chemicals, liquid acids as well as acidic vapours, salts and bases, and bacteria.

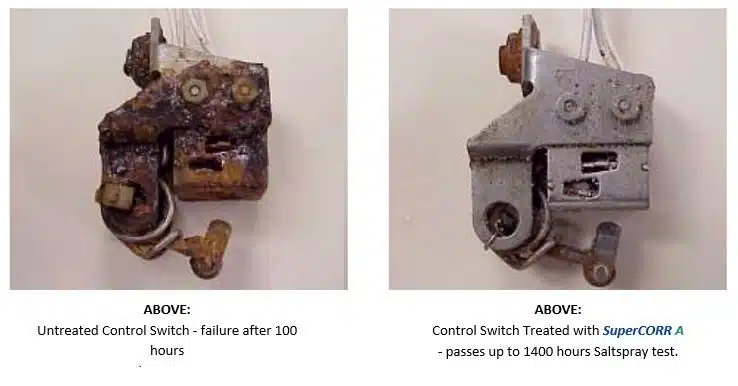

The U.S. Navy selected Super CORR A after exhaustive testing using American Society for Testing and Materials (ASTM) Standard B117- Standard Practice for Operating Salt Spray Apparatus.

Super CORR A out-performed 11 other products in comparative testing to identify a better product to protect and lubricate the flap tracks and screw jacks on the aircraft. Super CORR A was evaluated against competitive products under the Federal Test Method Standard #791B, using a five percent Salt Spray Corrosion Test.

The use of Super CORR A in regular maintenance procedures can bring financial savings in reduced maintenance and replacement costs, and more importantly, greater safety.

Maintenance of contacts on portable gas generators

A leading manufacturer of connectors tested Super CORR A to see what the “life” of the lubricant was in a “rub test”. The typical test is 20,000 cycles, i.e. unplug, plug in is one cycle. The test results demonstrated that after 20,000 cycles there were no failures. It was decided to take it one more step and run the same tests for 200,000 cycles. The results again showed no indications of galling or scoring on the connectors at all. The connector looked and tested as good as new. This test was run under clean conditions in a laboratory but demonstrates the effectiveness of the protective lubricant in Super CORR A.

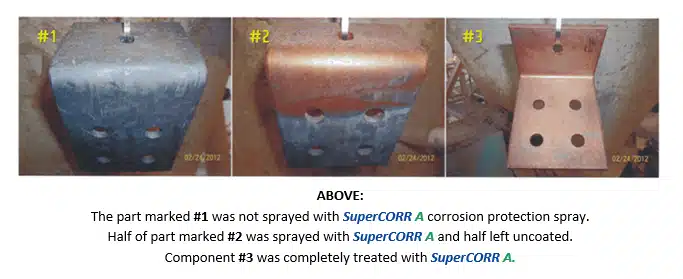

Unpainted metal in highly corrosive environments

Tests demonstrate the amazing properties of Super CORR A corrosion protection spray to protect unpainted metal surfaces from corrosion. These are photographs of 3 unpainted copper components that were exposed for a month next to the “digester” at a Pulp and Paper Mill.

The main atmospheric corrosion was from hydrogen sulphide (H2S) gas, produced during the cellulose digestion process, which combines with the atmospheric humidity to form a mild acid. Any unpainted or untreated metal surface, copper, brass, mild steel or alloys of zinc and manganese or magnesium will be corroded by this acid when it condenses on the metal surfaces.

Tests demonstrate the amazing properties of Super CORR A to protect unpainted surfaces from acidic corrosion. As an example, copper and aluminium condensers on water coolers usually last about a month in the acidic environment of pulp production facilities because the corrosive atmosphere around the plant corrodes the metal surfaces on fins and connections.

Super CORR A has been also used to protect contacts on the Lifedge lightning connector to USB cable to offer the protection needed in extreme conditions. During the design of this new cable an extensive test programme was carried out by Scanstrut to ensure the contacts were protected from corrosion in the salty and hostile environments in which the connectors are used.

CONCLUSION

It is clear the use of Super CORR A for corrosion control can not only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace the damaged equipment or component that failed because of corrosion. As you have seen The photographs show the effects of protecting metal surfaces and components in extreme condition with Super CORR A.

Super CORR A is packaged in aerosol cans making access to component parts easy for engineering crews in difficult locations and conditions. Unpainted mild steel will not rust on exterior surfaces directly exposed to sea water environments for at least 6 months, protecting electrical connectors, switches, chains, drive shafts from corrosion while maintaining lubrication on moving surfaces.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

APPROVED

- Industry approval from: NASA, Boeing Aircraft, Bombardier, Embraer, Lear, Gulfstream, Hawker-Beechcraft, Cessna, Raytheon, Polish Airforce, Northrop-Grumman, Royal Navy and Royal Norwegian Air Force.

- Exceeds Mil C 81309 Corrosion Prevention Compounds.

- Approved in US Tri-Service Corrosion Manuals.

References

[1] https://heat-exchanger-world.com/featured-story-the-cost-of-corrosion-microbial-corrosion-in-heat-exchange

[2] http://impact.nace.org/economic-impact.aspx

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Vapour degreasing engineering fluid for precision cleaning applications

Vapour degreasing engineering fluid for precision cleaning applications

A fluorocarbon vapour degreasing engineering fluid for precision cleaning applications that has been developed by EnviroTech Europe Ltd for parts cleaning or cleaning automated machinery at strip down.

ProSolv® 5408e offers future-proof cleaning and can offer savings without compromising quality. Substitution is simple with little or no changes to equipment or control settings needed. Friendly to the environment it has zero Ozone Depletion Potential (ODP) and a very low impact on Global Warming (GWP). In addition, it is a non-flammable stable azeotrope needing no testing for acid acceptance or stabilising additives, easy to use and maintain and safer for employees and the workplace.

ProSolv® 5408e is extremely effective for precision cleaning in high-tech industries such as aerospace, aviation, electronics and medical device cleaning due to the use of an additive trans 1,2-dichloroethylene. This produces a powerful cleaning solvent with a very low surfaces tension that cleans blind holes and the smallest gaps more effectively at a lower cost. With these wide range of properties ProSolv® 5408e is particularly effective when used with ultrasonics.

ProSolv® 5408e can usually be used in existing degreasers or dip tanks. The fluorinated solvents are ideal for the cost-conscious user for precision cleaning and degreasing of electronics, metals and glass. It can be used to remove adhesives, fluxes, pastes, buffing compounds, greases, silicone oils, particulates, resins, waxes and other oils and soils.

Zero Ozone Depletion Potential (ODP) and very low Global Warming Potential (GWP) solvent blend for high performance vapour degreasing

ProSolv® 5408e ticks all the boxes with the perfect profile for a vapour degreasing solvent, developed by EnviroTech Europe Ltd for precision parts cleaning or cleaning automated machinery at strip down.

ProSolv® 5408e offers improved cleaning at a lower cost, without compromising quality. Substitution is simple with little or no changes to equipment or control settings needed. A non-flammable stable azeotrope needing no testing for acid acceptance or stabilising additives, easy to use and maintain and safer for the workplace.

ProSolv® 5408e is extremely effective for precision cleaning in high-tech industries such as aerospace, aviation, electronics and medical device cleaning. It can be used in most solvent cleaning systems, one tank vapour degreasing or multi tank immersion / vapour tank systems using ultrasonics or flush cleaning for complex mechanical and electronic components with blind holes and channels and close mounted electronics or for removing grinding and buffing soils on surfaces. Exceptionally low surface tension to penetrate micron sized holes and close contact surfaces.

ProSolv® 5408e is highly effective when used with ultrasonics and can usually be used in existing degreasers or dip tanks. Ideal for precision cleaning and degreasing of electronics, metals and glass. It can be used to remove adhesives, fluxes, pastes, buffing compounds, greases, silicone oils, particulates, resins, waxes and other oils and soils. Soft on the environment, low solvent losses, reduced costs, sustainable and secure for the future.

BENEFITS

EFFICIENT AND ECONOMICAL

- Fast precision cleaning, short cycle times. Stable with no additives, no testing required

- Alternative to Methylene Chloride, Perchloroethylene and High ODP/GWP Fluorocarbons

- Excellent choice to replace flammable solvents such as MEK, Acetone, Isopropyl Alcohol (IPA) or Hydrocarbons

- Established replacement for Trichloroethylene, n-Propyl Bromide (nPB) and other now banned solvents

- Can be used in any vapour degreasing equipment, lower energy consumption and lower maintenance. Compatible with a broad range of substrates

- Improved productivity, parts exit the machine cool, dry, spot-free with no drying required

- High density solution, excellent for ultrasonic cleaning

- Mid-range temperature operation, easier handling, mid-range boiling point, processed components easily handled (48°C)

- Very low surface tension for penetration into the micron level crevices and holes, efficient cleaning in tight to reach places and complex geometries

- Easy process monitoring with minimal effort and minimal waste generation, easy reclamation for reuse

- Minimal non-volatile residue

- High Solvency (KB Value 98) for a variety of contaminants

SAFE FOR USERS AND THE ENVIRONMENT

- Safe for the environment, zero Ozone Depletion Potential (ODP)

- Very low impact on Global Warming (GWP)

- Non-hazardous for transportation

- Non-flammable (No Flash Point)

- Not classified as a carcinogen

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/prosolv5408e for information about other uses and applications for ProSolv 5408e.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Latest News

Lubricant And Corrosion Inhibitors

How SuperCORR A protective lubricant prevents seizures of automatic handling systems in the harsh conditions of Industrial cleaning systems.

Specialist cleaning equipment manufacturer C&C Hydrosonics a division of U.S giant Crest Ultrasonics have solved a problem with seizures occurring the on x-y axis linear tracks on their automatic handling systems fitted to multi tank cleaning systems both aqueous and solvent based.

The automatic handling systems are programmed to process baskets or jigs through a cleaning cycle transferring between tanks, lowering and raising work from the liquids. The motorised carriages use nylon wheels running on case hardened mild steel tracks (stainless steel is not available) which corrode in the chemical atmospheres in the machine canopies.

The corrosion prevents smooth running with wheels seizing and binding on the tracks. The vibration can cause components to be shaken from jigs or in extreme cases the carriage will stall requiring intervention by service engineers to remove corrosion and re-lubricate tracks with oil. This is a temporary measure as the oil is quickly removed by the solvents and water based cleaning solutions with corrosion recurring in a short time.

SuperCORR A from EnviroTech Europe is an innovative dry lubricant formulation with protective properties which forms a self-healing film applied from an aerosol. The inorganic lubricant is unaffected by water and acts a barrier against rusting and corrosion. Extensive Trials by C&C Hydrosonics over a six month period with both solvent and water based systems demonstrated that SuperCORR A offered a simple solution to the problem with no seizures during the trial period. Previously maintenance every six weeks was needed, now an aerosol spray of SuperCORR A is used only during service visits as a routine lubrication and applied during production of the handling system.

Lee Casey Managing Director of C&C is delighted with the cost savings on reduced service and maintenance calls using SuperCORR A but is even more pleased that the inconvenience to customers has been eliminated. Use of SuperCORR A has now been extended worldwide on Crest automated handling systems.

SuperCORR A is available from EnviroTech Europe Ltd and distributors worldwide.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

The only realistic “drop in” replacement for TRIKE.

CONTENT ON THIS PAGE IS RETAINED FOR INFORMATION ONLY

DUE TO n-Propyl bromide now being included in Annex 14 of REACH

EnviroTech Europe Ltd (ETE) continue to publish it as historical information and to record changes occurring in legislation which have affected decisions on formulations and equipment used in vapour degreasing - the most effective, quickest, flexible and cheapest cleaning system used in industry.

EnSolv® invented and patented by EnviroTech has been a market leader all over the world for vapour degreasing. It is based on n-bromopropane (nPB) which now cannot be used as a vapour degreaser within the UK or EU without authorisation.

Archived information about EnSolv® can be found using the Discontinued Products & Resources navigation menu on this page.

Using experience accumulated over 40 years supplying and supporting users of the vapour degreasing process ETE specialists have developed “drop in” alternatives:

ProSolv®, ProSolv5408e® and EnSolv CC-A® give the same or improved level of performance and economy as the original EnSolv® products.

Please contact our advisers who are available to discuss your needs and propose the best replacement product.

Or please click here to return to our vapour degreasing products homepage for information about our current products.

|

|

Why EnSolv is the only realistic “drop in” replacement for TRIKE as a Vapour Degreasing Solvent.

Syd Treacher, a Surface Cleaning Consultant discusses the current controversy regarding replacements for trichloroethylene, the most commonly used vapour degreasing solvent, which was to be phased out of use in industrial applications in April 2016.

This article was prompted while reading an article where the author claimed that a grade of fluorocarbon solvent was a “drop in” replacement for TRIKE (trichloroethylene) and n- propyl bromide. This statement is not true for the majority of applications for which trichloroethylene is used – vapour degreasing or more correctly condensation cleaning.

As a consultant in surface cleaning technology I have studied the options available and come to the conclusion that the stabilised n-propyl bromide (nPB) sold in the UK under the brand name EnSolv® is the ONLY realistic “drop in” replacement for trichloroethylene when used for vapour degreasing. It is on average up to 50% cheaper than fluorocarbon formulations being proposed as alternatives.

From my evaluation it is clear current users of EnSolv® can continue to use the solvent and equipment or if still if using TRIKE you can make the change to EnSolv® in a day. A decision has to be made quickly as the “sunset date” after which TRIKE will not be available for industrial use without authorisation in the EU was April 2016 but you can substitute with only minor changes to control settings on equipment. The legislation regarding the use of nPB may change in the future but if this happens you will have at least 3 years to decide on the alternative so the savings in solvent costs over this period will be considerable compared to alternative materials. Read the full article here.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Degreasing And Cleaning – Key Questions To Ask

There can be no doubt that manufacturers of metal components have remained keenly interested in the advantages to be found in process cleaning, while being confused by the amount of misinformation that seems presented to them.

There can only be two reasons for this. These is an intention to mislead or simply a lack of understanding of the subject.

In any event, the user needs to take time to match what is said to what is fact. Too often companies generalise on the basis that they are not keen for users to look deeply at the subject, yet this is vital if good decisions are to be made.

In the end, the final judgement of the user is what matters but how many people express frustration at some of the suppliers they have met who spent more time criticising a proven product rather than validating their own.

Too often, suppliers are advising what not to do rather than dealing with what really works. This is negative selling and appears on the increase as the market shrinks, regulation gets tighter and independent specialists are more limited in numbers.

Recent history suggests that larger suppliers rely on their size to justify their competence when in fact the really satisfied customers are saying smaller companies with real specialists provided the best solutions.

No one can argue against the fact that the popular choice for metal cleaning and degreasing is still vapour degreasing. This is confirmed by the companies involved in making machinery for degreasing. The order books are heavily stacked in favour of vapour degreasing. If there is one slight disadvantage currently, lead times are often 20 weeks to delivery of machines.

It is clear though that these highly cost-effective systems, which use very little solvent, are likely to remain the first choice for some considerable time.

Arguments related to the Solvent Emissions Directive carry little weight with modern machines as they are so well engineered that they are compliant with regulatory requirements. If there is one common request made by users it remains that they wish there was a single company capable of offering the total solution, e.g. both their own product and machinery together. This would shorten the circle and place more pressure on the supplier to be responsible for promises made.

Most machinery companies work with a multitude of chemistry suppliers, since they want the maximum sale of machines, but should disputes arise this can be a protracted problem as it’s easy to blame someone else for the issues involved.

Much is said about vacuum and hermetically sealed systems being the best solution. They are certainly the most expensive. Speak to an independent specialist to ensure you know the limits of these machines and the cost benefits of alternative designs.

Suppliers who claim aqueous systems are superior need to ensure they advise the user that more energy, more space, longer cleaning cycles more risk of residues and waste disposal issues should be taken into account. Global warming is an issue for all of us so factor in the amount of energy required for heating and drying. To accept that water is safer or better, needs to be well argued. Never forget that water-based cleaning solutions need changing regularly and the oils and metals produced by these processes are waste and needs correct and very expensive disposal.

When considering vapour degreasing it will often be suggested that product transfer systems attached to the existing open-topped machine bring a number of benefits. For handling benefits it is true but never doubt they will not contribute to reducing your consumption, so will do nothing for emission targets.

The best way forward is to make a supplier talk to you about their own product. Beware of those who distract you from this. If a claim is made that seems suspect, ask for the claims to be made in writing. Transparency is a vital ingredient in any relationship with your supplier.

The target audience for most suppliers are those using the carcinogen Trichloroethylene. This is now banned for general use and requires specific authorisation for use in cleaning applications. Do your research, set the questions and insist on the evidence for the arguments put forward. Protecting your business, your staff and the community around you gives a sound basis to ensure a real assessment.

For more information about Vapour Degreasing Solutions please visit our website:

www.vapour-degreasing.com

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Replace Banned Trichloroethylene

CONTENT ON THIS PAGE IS RETAINED FOR INFORMATION ONLY

DUE TO n-Propyl bromide now being included in Annex 14 of REACH

EnviroTech Europe Ltd (ETE) continue to publish it as historical information and to record changes occurring in legislation which have affected decisions on formulations and equipment used in vapour degreasing - the most effective, quickest, flexible and cheapest cleaning system used in industry.

EnSolv® invented and patented by EnviroTech has been a market leader all over the world for vapour degreasing. It is based on n-bromopropane (nPB) which now cannot be used as a vapour degreaser within the UK or EU without authorisation.

Archived information about EnSolv® can be found using the Discontinued Products & Resources navigation menu on this page.

Using experience accumulated over 40 years supplying and supporting users of the vapour degreasing process ETE specialists have developed “drop in” alternatives:

ProSolv®, ProSolv5408e® and EnSolv CC-A® give the same or improved level of performance and economy as the original EnSolv® products.

Please contact our advisers who are available to discuss your needs and propose the best replacement product.

Or please click here to return to our vapour degreasing products homepage for information about our current products.

Trichloroethylene is banned by the EU and will not be available after 21 April 2016.

Still using trichloroethylene for vapour degreasing?

The final EU “Sunset Date” is on 21 April 2016 when use of this solvent will be illegal without specific authorisation and unless very expensive fully enclosed vacuum equipment is installed. Exemptions are unlikely if an alternative is available.

Replace Trike now with EnSolv – the simple “drop in” replacement for Trichloroethylene.

EnSolv is stable, economical, a superb vapour degreaser operating at 70˚C which means less energy, easier handling, faster throughput and lower usage. Very safe for operators, EnSolv is a simple replacement using existing equipment which needs no new skills – resetting the thermostats is all that’s necessary.

Alternative solvents based on fluorocarbons are available but are not “drop in” replacements and are very expensive. The equipment needed to use these materials is not available off the shelf with equipment manufacturers quoting months for delivery.

EnSolv is supplied and serviced by an experienced, expert group of distributors, fully trained to carry out inspections of your equipment and processes and advise and support the changeover which can be done in hours.

A visit to your works by a member of our Trichloroethylene Substitution Team to survey, report and process samples to validate cleaning and compatibility with soils, oils and metals of construction is completely free and without obligation. You are also welcome to personally visit our Technical Centre, close to Stansted Airport, to test samples yourself and discuss your needs with our experts.

An alternative to vapour degreasing is water based cleaning systems. EnviroTech Surface Technologies can supply suitable materials for appropriate needs where the next part of the process, anodising or electroplating are water based or where use of solvent is not compatible with the materials used in manufacturing of components. But the installation costs, use of multi tanks taking up space which could be used for more productive and profitable uses, disposal of water and energy costs for drying are not economical when compared to simple substitution, by EnSolv using existing equipment.

We have the all facts for you to consider before you make the commitment. Call on the number below or go to our product website www.vapour-degreasing.com and book a free visit by one of the experts from our Trichloroethylene Substitution Team.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Don’t Miss The Trichloroethylene Deadline

|

Trichloroethylene due to be phased out in April 2016.

ProSolv is a new, less expensive fluorinated solvent formulation for all precision cleaning applications.

ProSolv the new critical cleaning solvent has been developed by EnviroTech Surface Technologies as a “drop in” cost effective alternative which is less expensive than the current fluorocarbon formulations you may be using.

ProSolv offers future proof cleaning systems giving long term savings without compromising quality. Substitution is simple with no changes to equipment or control settings needed.

Users of trichloroethylene, which is due to be phased out as a cleaning solvent in April 2016, only 3 months away, may be able to use ProSolv as a cost effective replacement in many applications.

ProSolv is friendly to the environment it has zero Ozone Depletion Potential (ODP) and a very low impact on global warming. In addition, it is a non-flammable stable azeotrope needing no testing for acid acceptance or stabilising additives, easy to use and maintain and safer for employees and the workplace.

ProSolv like many other fluorinated solvent azeotropes is extremely effective for precision cleaning in hightech industries such as aerospace, aviation, electronics and medical due to the use of an additive trans 1,2-dichloroethylene.

This produces a powerful fluorinated cleaning solvent with a very low surfaces tension which cleans blind holes and the smallest gaps more effectively at a lower cost. With these wide range of properties ProSolv is particularly effective used with ultrasonics.

ProSolv can usually be used in existing degreasers or sprayed from an aerosol container. Our fluorinated solvents are ideal for the cost-conscious user for precision cleaning and degreasing of electronics, metals and glass.

ProSolv can be used to remove adhesives, fluxes, pastes, buffing compounds, greases, silicone oils, particulates, resins, waxes and other oils and soils.

ProSolv is only one of a wide range of cleaning solvents and solutions produced by engineering cleaning specialists EnviroTech Surface Technologies. Our Technical Centre in Essex is available for you to visit to test clean your components with ProSolv or compare results with the other products such as EnSolv or Clarea solvents we supply. Our technical team have extensive knowledge of equipment and systems to help you find the most effective, budget-friendly, future proof and environmentally conscious solution for your business. EnviroTech Surface Technologies have distributors located across the E.U. and Middle Eastern countries all of whom can offer technical advice and support.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Replace Trichloroethylene with ProSolv

Are you still using Trichloroethylene for Vapour Degreasing?

High performance cleaning at a lower cost than other fluorinated solvent cleaners

Trichloroethylene will not be obtainable for metal cleaning or other uses without authorisation after April 2016.

ProSolv® enables high performance cleaning at a lower cost than other fluorinated solvent cleaners. A proprietary tertiary azeotropic formulation based on a fluorinated solvent which provides a direct replacement for trichloroethylene and other chlorinated solvents.

ProSolv® is extremely stable and simple to use meeting all the increasingly stringent legislative demands for safer, non flammable solvents with a low environmental impact in the precision engineering industries.

ProSolv® can be used in most existing vapour degreasing equipment and can be used safely for immersion cleaning using ultrasonics, where it has been optimised with a high specific gravity and very low surface tension.

Unlike other chlorinated solvents ProSolv® can be used for manual cleaning in a suitably ventilated area. Typical applications are where high performance critical cleaning is required at lower cost than other fluorinated solvent cleaners. Vapour degreasing for medical, aerospace, optics, oxygen equipment service, high vacuum components and electronics.

ProSolv® is an excellent choice to replace flammable solvents such as MEK, Acetone, Iso propyl alcohol (IPA) or hydrocarbons where manual wiping or brush cleaning is the preferred cleaning method.

ProSolv® is a stable azeotrope which can be recycled by distillation for reuse through many cycles. It is a very stable mixture with no need for monitoring or the need for additives or stabilisers.

ProSolv® offers a cost effective replacement in formulations for dip, spray or aerosol applications and as a fast drying carrier solvent for oil, silicones and other lubricants.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

SuperCORR A Keeps Flight MH370 search planes flying

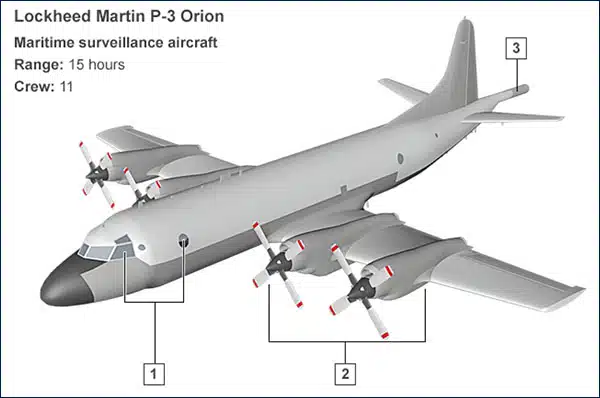

ABOVE:

1. The Lockheed Martin P-3 Orion is equipped with radar and infrared sensors as well as observation posts to help detect any debris on the surface of the ocean. It also has three cameras beneath the landing gear capable of zooming in for a closer look.

2. The four-engine turboprop plane is designed to fly low and slow to aid surveillance. Once it has reached the search location, one or two outer engines can be turned off to preserve fuel and extend the surveillance time.

3. The plane is also fitted with a magnetic anomaly detector (MAD) – used for detecting submarines underwater. The aircraft also has acoustic detectors, which are able to detect sound 1,000ft (304.8m) below the surface of the ocean.

SuperCORR A lubricant keeps Flight MH370 search planes flying

SuperCORR A the lubricant and anti-corrosion formulation from the CORR-EX division of EnviroTech Surface Technologies is helping in the search for the missing Malaysia Airlines flight MH370 passenger jet.

Lockheed Martin AP-3C Orion’s aircraft of the Royal Australian, Korean and Japanese Air Forces used for anti-submarine and maritime surveillance are still searching for debris in a vast area of ocean, bigger than the land area of Europe, southwest of Perth. The maintenance schedules specify SuperCORR A to lubricate and protect the flap tracks and screw jacks in the wings of the aircraft.

SuperCORR A lubricant and protective coating is widely used by the military, electronics and aerospace industries for critical applications to give the protection needed in extreme conditions. SuperCORR Adeposits a dry protective film with excellent corrosion protection and lubricant properties plus the added advantage of a hydrophobic surface rejecting water that ensures the easiest and best connections for very close spaced connectors, contacts, wiring and moving parts.

The U.S. Navy selected SuperCORR A after exhaustive testing using American Society for Testing and Materials (ASTM) Standard B117- Standard Practice for Operating Salt Spray Apparatus. SuperCORR A, a Type I, Grade B Corrosion Preventative lubricant out-performed 11 other products in comparative testing to identify a better product to protect and lubricate the flap tracks and screw jacks on the aircraft.

The flap tracks, located in the aircrafts wings, are what the flaps slide on when they move up or down to lower or increase speed. The screw jacks engage and retract the wing flaps. Corrosion on any of the surfaces can lead to snatching or vibration which can affect the pilots control.

Due to constant operation in salty and corrosive atmospheres which need post-flight rinses and monthly washing down of the aircraft re-lubrication and corrosion treatment for the flap tracks and screw jacks is required each time, with conventional lubricants, to prevent rusting. SuperCORR A was evaluated against competitive products under the Federal Test Method Standard #791B, using a five percent Salt Spray Corrosion Test.

SuperCORR A far exceeded the other products evaluated. After over 200 hours of continuous exposure to salt spray corrosion, SuperCORR A’s protection actually increased over time where the other similar products failed early or contributed to an increase in corrosion.

The accelerated salt fog corrosion testing demonstrated that the application of SuperCORR A which complies with MIL-L-87177A also increased electrical operation to 1400 hours versus 100 hours for the control product used at that time. Technical manuals were updated to include the application for electrical and mechanical parts for civilian and military operations.

The most important conclusion from the historical data and prototype testing is the availability of this excellent corrosion preventive compound that has dry film lubricant properties. The application of SuperCORR A on aircraft components can reduce maintenance man hours, reduce part replacement costs, increase life of aircraft, increase safety, and increase readiness.

Estimates for the maintenance cost for the US Air Force F-16 fleet can reach $500 million per year, the use at all military branches could reach billions of dollars per year. Applications at locations tested by the U.S. Air Force are not normally treated with corrosion prevention and control lubricants (CPC’s) These are the electrical connectors that are susceptible to subtle and not so subtle forms of corrosion that could interfere with the electrical operation of the F-16.

Testing by the U.S. Navy at NADEP Jacksonville incorporates not only electrical connectors, but mechanical and structural components as well. Future uses will also include ground support equipment. The properties of SuperCORR A are such that it can be used on a wide variety of applications and any materials, metal or plastic. Properties of the SuperCORR A far exceed the requirements defined by the MIL-L-87177A specification. Many beneficial properties of the product are not required in the MIL specification.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

EnSolv and the Environment – Update from the Co Chairman of the United Nations Ozone Assessment panel on nPB.

CONTENT ON THIS PAGE IS RETAINED FOR INFORMATION ONLY

DUE TO n-Propyl bromide now being included in Annex 14 of REACH

EnviroTech Europe Ltd (ETE) continue to publish it as historical information and to record changes occurring in legislation which have affected decisions on formulations and equipment used in vapour degreasing - the most effective, quickest, flexible and cheapest cleaning system used in industry.

EnSolv® invented and patented by EnviroTech has been a market leader all over the world for vapour degreasing. It is based on n-bromopropane (nPB) which now cannot be used as a vapour degreaser within the UK or EU without authorisation.

Archived information about EnSolv® can be found using the Discontinued Products & Resources navigation menu on this page.

Using experience accumulated over 40 years supplying and supporting users of the vapour degreasing process ETE specialists have developed “drop in” alternatives:

ProSolv®, ProSolv5408e® and EnSolv CC-A® give the same or improved level of performance and economy as the original EnSolv® products.

Please contact our advisers who are available to discuss your needs and propose the best replacement product.

Or please click here to return to our vapour degreasing products homepage for information about our current products.

|

| view/ download this document in Adobe Acrobat Format |

Analysis of Status on Science of n-PB Effects on Ozone

White Paper By Don Wuebbles (Department of Atmospheric Sciences – University of Illinois).

November 11, 2014

There is disagreement between the use of scientific information by the European Union and the United Nations Environmental Panel / World Health Organisation (UNEP/WHO) the authority for ozone depletion assessment. Dr. Don Weubbles acknowledged as one of the world authorities on ozone depletion and who Co Chaired the UNEP/WHO 2014 ozone assessment panel explains in detail why the official world study disagrees with the European Union Environment Agency 2014 assessment as not being supported by science.

EnSolv is safe for the environment backed by the most sophisticated and knowledgeable world scientists.

Analysis of Status on Science of n-PB Effects on Ozone

Don Wuebbles

Department of Atmospheric Sciences

University of Illinois

Urbana, IL

Phone (217) 244-1568

Email:Wuebbles@illinois.edu

November 11, 2014

I co-led chapter 5 (with Neil Harris of Cambridge University) of the 2014 WMO-UNEP ozone assessment that is currently in press (the summary, Assessment for Decision Makers, was released in September 2014 (WMO-UNEP, 2014)). Chapter 5, titled Scenarios and Information for Policymakers, of the full assessment, examines the latest understanding of a number of Ozone Depleting Substances (ODSs) including the available analyses of Very Short Lived Substances (VSLS) like n-propyl bromide (n-PB; C3H7Br). The full assessment will be released in early 2015 as a web-based report.

In Chapter 5 of the full assessment, we include the following text related to the evaluation of VSLS like n-PB:

Table 5-3 shows analyses of the spatial dependence in ODPs for VSLS primarily based on results using different versions of the NCAR global 3-D model (Wuebbles et al., 2009, 2011; Patten and Wuebbles, 2010; Youn et al., 2010; Patten et al., 2011). Note that this model calculates an atmospheric lifetime of 53.7 years for CFC-11, so the published ODPs would not be significantly affected by the revised SPARC (2013) lifetime for CFC-11. In these studies, the VSLS examined all have quite small ODPs based on emissions occurring primarily at midlatitudes. New approaches for estimating VSLS ODPs have been developed since WMO (2011) based on Lagrangian models (Tegtmeier et al., 2012; Pisso et al., 2010; Brioude et al., 2010), with similar findings to previous studies, except for emissions in the tropics where a different treatment of convection may allow for more VSLS (and their products) to reach the stratosphere.

The reported atmospheric lifetime and Ozone Depletion Potential (ODP) for n-PB in Table 5-3 for midlatitude emissions (30-60N), based on the 3-D chemistry-climate modeling studies of Wuebbles et al. (2011), are 24.7 days and 0.0049, respectively.

At the same time, we noted:

Earlier studies (Wuebbles et al., 1999, 2001; Olsen et al., 2000; Bridgeman et al., 2000) have shown that the ODPs for short-lived compounds depend greatly on when or where the emissions occur, with the largest ODPs being found for emissions in the tropics. Although it is generally expected that most emissions from anthropogenic emissions of VSLS will occur at Northern midlatitudes, there is no guarantee of this and the locations of future emissions could change.

In addition, we also reported upon an indirect study of the ODP using a semi-empirical approach based on the Lagrangian model analysis of Brioude et al. (2010). The results in Table 5-4 of WMO-UNEP Chapter 5 are taken from the Supplementary materials for that published paper. The results in Table 5-4 are quite a bit higher than Wuebbles et al. (2011) and show an ODP for n-PB of 0.0235 (0.0150-0.032) for North America emissions and 0.0150 (0.0070-0.0260) for European emissions. However, as noted in the chapter, the Brioude et al. results may be an overestimate because they do not properly account for reaction loss in the troposphere and therefore may have overestimated the amount of n-PB reaching the stratosphere. As stated in the Chapter:

The recent modeling studies also re-emphasize the point that VSLS ODPs are very dependent on the location of emissions, and not just the latitude; for example, by co-location with efficient vertical transport by deep convection into the stratosphere (semi-empirical ODPs as a function of specific locations of emissions based on Brioude et al. (2010) are shown in Table 5-4). Brioude et al. (2010) showed that these factors are more important than regional variations in VSLS losses by OH or photolysis. Using CO-like emissions to represent anthropogenic VSLS, they estimated ODPs for various compounds and found maximum ODPs over the Indian sub-continent varying from 0.079 in winter to 0.29 in summer for n-propyl bromide (C3H7Br or nPB) and from 0.13 in winter to 0.83 in summer for CH3I. Pisso et al. (2010) applied their new methodology to an nPB-like tracer with a lifetime of 20 days. They also found higher ODPs over southeast Asia in the summer (and over western Pacific in winter). In July in the tropics (30°N-30°S), ODPs varied from 0.33 in runs with convection to 0.17 in runs with no convection. Locally, values over southeast Asia are as high as 1.00. In general the results from these Lagrangian studies predict higher ODPs regionally compared to the global model results. These differences highlight uncertainties in simulating the transport of VSLS, with boundary layer mixing, convection depth and advection strength all possibly leading to local differences in VSLS delivery to the stratosphere (e.g., see Hossaini et al., 2012b; Feng et al., 2011; Hoyle et al. 2011). The global model studies (e.g., Wuebbles et al., 2011) used a full chemical treatment for VSLS and CFC-11 degradation in the stratosphere and more realistic degradation and wet deposition schemes for VSLS in the troposphere than the Lagrangian based studies (e.g., Tegtmeier et al., 2012; Pisso et al., 2010), leading to less VSLS reaching the stratosphere. Overall, these results point to potentially more important impacts from VSLS if emissions occur in regions close to convective regions in the tropics.

The 2014 report from the European Environment Agency, Ozone-Depleting Substances 2013, examines the European reporting requirement for n-PB and determines a total import of nPB to Europe of 1014.3 metric tonnes and a weighted ODP-tonnes for imported nPB of 101.4. This suggests they used an ODP of 0.1 for n-PB. This is far too large by either the Wuebbles et al. (2011) or the Brioude et al. (2010) analyses by roughly a factor of 6.7 for Europe emissions using the Brioude et al approach and a factor of 20.4 using the Wuebbles et al. 3-D model results. Because Wuebbles et al. may have underestimated the convection based on the observations used in the Brioude et al. study, the reality is likely somewhere between the two results, but this still suggests that the European Environment agency still used an ODP a factor of 10 or more too large. The science does not support the ODP used by the European Environment Agency.

References

Bridgeman, C.H., J.A. Pyle, and D E. Shallcross, A three-dimensional model calculation of the ozone depletion potential of 1-bromopropane (1-C3H7Br), J. Geophys. Res., 105, 26,493-26,502, 2000.

Brioude, J., R.W. Portmann, J.S. Daniel, O.R. Cooper, G.J. Frost, K.H. Rosenlof, C. Granier, A.R. Ravishankara, S.A. Montzka, and A. Stohl, Variations in ozone depletion potentials of very short-lived substances with season and emission region, Geophys. Res. Lett., 37, L19804, doi: 10.1029/2010GL044856, 2010.

European Environment Agency, 2014: Ozone-Depleting Substances 2013. EEA Technical Report No. 14/2014, Copenhagen.

Olsen, S.C., B.J. Hannegan, X. Zhu, and M.J. Prather, Evaluating ozone depletion from very short-lived halocarbons, Geophys. Res. Lett., 27, 1475-1478, 2000.

Patten, K.O., and D.J. Wuebbles, Atmospheric lifetimes and Ozone Depletion Potentials of trans-1-chloro-3,3,3-trifluoropropylene and trans-1,2-dichloroethylene in a three-dimensional model, Atmos. Chem. Phys., 10, 10867-10874, 2010.

Patten, K.O., V.G. Khamaganov, V.L. Orkin, S.L. Baughcum, and D.J. Wuebbles, OH reaction rate constant, IR absorption spectrum, ozone depletion potentials and global warming potentials of 2-bromo-3,3,3-trifluoropropene, J. Geophys. Res., 116, D24307, doi:10.1029/2011JD016518, 2011.

Pisso, I., P.H. Haynes, and K.S. Law, Emission location dependent ozone depletion potentials for very short-lived halogenated species, Atmos. Chem. Phys., 10, 12025-12036, 2010.

SPARC (Stratospheric Processes And their Role in Climate), Report on the lifetimes of stratospheric ozone-depleting substances, their replacements, and related species, M. Ko, P. Newman, S. Reimann, S. Strahan (Eds.), SPARC Report No. 6, WCRP-15, Zurich, Switzerland, 2013

Tegtmeier, S., K. Krüger, B. Quack, E.L. Atlas, I. Pisso, A. Stohl, and X. Yang, Emission and transport of bromocarbons: from the West Pacific ocean into the stratosphere, Atmos. Chem. Phys., 12, 10633-10648, doi:10.5194/acp-12-10633-2012, 2012.

WMO-UNEP (coauthor), 2014: Assessment for Decision-Makers: Scientific Assessment of Ozone Depletion 2014. WMO Global Ozone Research and Monitoring Project – Report No. 56, Geneva, Switzerland; also available on WMO website.

Wuebbles, D.J., K.O. Patten, M.T. Johnson, and R. Kotamarthi, New methodology for Ozone Depletion Potentials of short-lived compounds: n-Propyl bromide as an example, J. Geophys. Res., 106, 14551-14771, 2001.

Wuebbles, D.J., D. Youn, K. Patten, D. Wang, and M. Martinez-Aviles, Metrics for ozone and climate: Three-dimensional modeling studies of Ozone Depletion Potentials and Indirect Global Warming Potentials, in Twenty Years of Ozone Depletion, C. Zerefos, G. Contopoulos, and G. Skalkeas, editors, Springer Publishing, Dordrecht, The Netherlands, doi: 10.1007/978-90-481-2469-5, p. 297-326, 2009.

Wuebbles, D.J., K. Patten, D. Wang, D. Youn, M. Martínez-Avilés, and J. Francisco, Three-dimensional model evaluation of the Ozone Depletion Potentials for n-propyl bromide, trichloroethylene and perchloroethylene, Atmos. Chem. Phys., 2011, 11, 2371-2380, 2011.

Youn, D., K.O. Patten, D.J. Wuebbles, H. Lee, and C.-W. So, Potential impacts of iodinated replacement compounds CF3I and CH3I on atmospheric ozone: a three-dimensional modeling study, Atmos. Chem. Phys., 10, 10129-10144, 2010.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page: