Latest Articles

Don’t Miss The Trichloroethylene Deadline

|

Trichloroethylene due to be phased out in April 2016.

ProSolv is a new, less expensive fluorinated solvent formulation for all precision cleaning applications.

ProSolv the new critical cleaning solvent has been developed by EnviroTech Surface Technologies as a “drop in” cost effective alternative which is less expensive than the current fluorocarbon formulations you may be using.

ProSolv offers future proof cleaning systems giving long term savings without compromising quality. Substitution is simple with no changes to equipment or control settings needed.

Users of trichloroethylene, which is due to be phased out as a cleaning solvent in April 2016, only 3 months away, may be able to use ProSolv as a cost effective replacement in many applications.

ProSolv is friendly to the environment it has zero Ozone Depletion Potential (ODP) and a very low impact on global warming. In addition, it is a non-flammable stable azeotrope needing no testing for acid acceptance or stabilising additives, easy to use and maintain and safer for employees and the workplace.

ProSolv like many other fluorinated solvent azeotropes is extremely effective for precision cleaning in hightech industries such as aerospace, aviation, electronics and medical due to the use of an additive trans 1,2-dichloroethylene.

This produces a powerful fluorinated cleaning solvent with a very low surfaces tension which cleans blind holes and the smallest gaps more effectively at a lower cost. With these wide range of properties ProSolv is particularly effective used with ultrasonics.

ProSolv can usually be used in existing degreasers or sprayed from an aerosol container. Our fluorinated solvents are ideal for the cost-conscious user for precision cleaning and degreasing of electronics, metals and glass.

ProSolv can be used to remove adhesives, fluxes, pastes, buffing compounds, greases, silicone oils, particulates, resins, waxes and other oils and soils.

ProSolv is only one of a wide range of cleaning solvents and solutions produced by engineering cleaning specialists EnviroTech Surface Technologies. Our Technical Centre in Essex is available for you to visit to test clean your components with ProSolv or compare results with the other products such as EnSolv or Clarea solvents we supply. Our technical team have extensive knowledge of equipment and systems to help you find the most effective, budget-friendly, future proof and environmentally conscious solution for your business. EnviroTech Surface Technologies have distributors located across the E.U. and Middle Eastern countries all of whom can offer technical advice and support.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Replace Trichloroethylene with ProSolv

Are you still using Trichloroethylene for Vapour Degreasing?

High performance cleaning at a lower cost than other fluorinated solvent cleaners

Trichloroethylene will not be obtainable for metal cleaning or other uses without authorisation after April 2016.

ProSolv® enables high performance cleaning at a lower cost than other fluorinated solvent cleaners. A proprietary tertiary azeotropic formulation based on a fluorinated solvent which provides a direct replacement for trichloroethylene and other chlorinated solvents.

ProSolv® is extremely stable and simple to use meeting all the increasingly stringent legislative demands for safer, non flammable solvents with a low environmental impact in the precision engineering industries.

ProSolv® can be used in most existing vapour degreasing equipment and can be used safely for immersion cleaning using ultrasonics, where it has been optimised with a high specific gravity and very low surface tension.

Unlike other chlorinated solvents ProSolv® can be used for manual cleaning in a suitably ventilated area. Typical applications are where high performance critical cleaning is required at lower cost than other fluorinated solvent cleaners. Vapour degreasing for medical, aerospace, optics, oxygen equipment service, high vacuum components and electronics.

ProSolv® is an excellent choice to replace flammable solvents such as MEK, Acetone, Iso propyl alcohol (IPA) or hydrocarbons where manual wiping or brush cleaning is the preferred cleaning method.

ProSolv® is a stable azeotrope which can be recycled by distillation for reuse through many cycles. It is a very stable mixture with no need for monitoring or the need for additives or stabilisers.

ProSolv® offers a cost effective replacement in formulations for dip, spray or aerosol applications and as a fast drying carrier solvent for oil, silicones and other lubricants.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

SuperCORR A Keeps Flight MH370 search planes flying

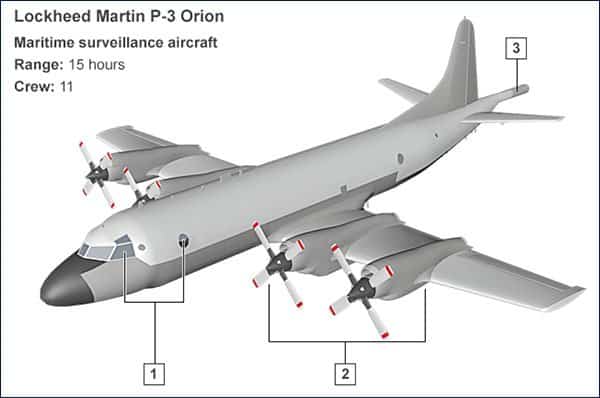

ABOVE:

1. The Lockheed Martin P-3 Orion is equipped with radar and infrared sensors as well as observation posts to help detect any debris on the surface of the ocean. It also has three cameras beneath the landing gear capable of zooming in for a closer look.

2. The four-engine turboprop plane is designed to fly low and slow to aid surveillance. Once it has reached the search location, one or two outer engines can be turned off to preserve fuel and extend the surveillance time.

3. The plane is also fitted with a magnetic anomaly detector (MAD) – used for detecting submarines underwater. The aircraft also has acoustic detectors, which are able to detect sound 1,000ft (304.8m) below the surface of the ocean.

SuperCORR A lubricant keeps Flight MH370 search planes flying

SuperCORR A the lubricant and anti-corrosion formulation from the CORR-EX division of EnviroTech Surface Technologies is helping in the search for the missing Malaysia Airlines flight MH370 passenger jet.

Lockheed Martin AP-3C Orion’s aircraft of the Royal Australian, Korean and Japanese Air Forces used for anti-submarine and maritime surveillance are still searching for debris in a vast area of ocean, bigger than the land area of Europe, southwest of Perth. The maintenance schedules specify SuperCORR A to lubricate and protect the flap tracks and screw jacks in the wings of the aircraft.

SuperCORR A lubricant and protective coating is widely used by the military, electronics and aerospace industries for critical applications to give the protection needed in extreme conditions. SuperCORR Adeposits a dry protective film with excellent corrosion protection and lubricant properties plus the added advantage of a hydrophobic surface rejecting water that ensures the easiest and best connections for very close spaced connectors, contacts, wiring and moving parts.

The U.S. Navy selected SuperCORR A after exhaustive testing using American Society for Testing and Materials (ASTM) Standard B117- Standard Practice for Operating Salt Spray Apparatus. SuperCORR A, a Type I, Grade B Corrosion Preventative lubricant out-performed 11 other products in comparative testing to identify a better product to protect and lubricate the flap tracks and screw jacks on the aircraft.

The flap tracks, located in the aircrafts wings, are what the flaps slide on when they move up or down to lower or increase speed. The screw jacks engage and retract the wing flaps. Corrosion on any of the surfaces can lead to snatching or vibration which can affect the pilots control.

Due to constant operation in salty and corrosive atmospheres which need post-flight rinses and monthly washing down of the aircraft re-lubrication and corrosion treatment for the flap tracks and screw jacks is required each time, with conventional lubricants, to prevent rusting. SuperCORR A was evaluated against competitive products under the Federal Test Method Standard #791B, using a five percent Salt Spray Corrosion Test.

SuperCORR A far exceeded the other products evaluated. After over 200 hours of continuous exposure to salt spray corrosion, SuperCORR A’s protection actually increased over time where the other similar products failed early or contributed to an increase in corrosion.

The accelerated salt fog corrosion testing demonstrated that the application of SuperCORR A which complies with MIL-L-87177A also increased electrical operation to 1400 hours versus 100 hours for the control product used at that time. Technical manuals were updated to include the application for electrical and mechanical parts for civilian and military operations.

The most important conclusion from the historical data and prototype testing is the availability of this excellent corrosion preventive compound that has dry film lubricant properties. The application of SuperCORR A on aircraft components can reduce maintenance man hours, reduce part replacement costs, increase life of aircraft, increase safety, and increase readiness.

Estimates for the maintenance cost for the US Air Force F-16 fleet can reach $500 million per year, the use at all military branches could reach billions of dollars per year. Applications at locations tested by the U.S. Air Force are not normally treated with corrosion prevention and control lubricants (CPC’s) These are the electrical connectors that are susceptible to subtle and not so subtle forms of corrosion that could interfere with the electrical operation of the F-16.

Testing by the U.S. Navy at NADEP Jacksonville incorporates not only electrical connectors, but mechanical and structural components as well. Future uses will also include ground support equipment. The properties of SuperCORR A are such that it can be used on a wide variety of applications and any materials, metal or plastic. Properties of the SuperCORR A far exceed the requirements defined by the MIL-L-87177A specification. Many beneficial properties of the product are not required in the MIL specification.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Latest News

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.