Latest Articles

The importance of corrosion protection for electrical systems

The importance of corrosion protection for electrical systems

Protection from corrosion is vital for safeguarding infrastructure and equipment, reducing costs, ensuring safety, and maintaining the reliability and longevity of critical electrical and electronic systems across various industries. Corrosion protection is critically important for several reasons.

Safety:

Corrosion can compromise the integrity of electrical components, leading to potential safety hazards. Damaged or corroded components can result in electrical short circuits, fires, or other dangerous situations.

Reliability:

Electrical systems are expected to function reliably over extended periods. Corrosion can lead to unexpected failures and downtime, disrupting operations and causing financial losses.

Performance:

Corrosion can degrade the performance of electrical connections, leading to increased resistance and reduced efficiency. This can result in wasted energy, increased operating costs, and reduced system performance.

Longevity:

Proper corrosion protection measures can extend the lifespan of electrical components and systems. By preventing or mitigating corrosion, you can reduce the frequency of maintenance and replacement, saving both time and money.

Energy Efficiency:

Corrosion can increase energy consumption. For example, in HVAC systems, corroded heat exchangers are less efficient, leading to higher energy bills.

Health and Safety:

Corrosion can compromise the safety of equipment and systems, leading to accidents and injuries. For instance, corrosion in the aviation industry can pose a significant risk to flight safety.

Reduced Maintenance Costs:

Dealing with the corrosion related issues listed above can be costly. Preventing corrosion through protective measures is always more cost-effective in the long run than repairing or replacing damaged components. Corrosion protection measures, such as coatings and inhibitors, can reduce the need for frequent maintenance and repair, saving both time and money.

Environmental Impact:

Corrosion can lead to the release of hazardous materials, such as lead, into the environment. Proper corrosion protection measures can reduce the environmental impact of electrical systems.

Economic Impact:

Corrosion costs industries billions of dollars each year in repair, maintenance, and replacement of corroded equipment. Effective corrosion protection measures can significantly reduce these costs.

Maintaining Signal Integrity:

In sensitive electronic systems, corrosion can affect the quality of signals and data transmission. For example, in telecommunications or data centres, corrosion-induced signal degradation can lead to communication errors, false signals or even data loss.

Aesthetic Considerations:

In some cases, electrical systems are visible to the public or customers. Corrosion can be unsightly and negatively impact the image and reputation of an organization.

Preventive Maintenance:

Implementing corrosion protection measures as part of a preventive maintenance program can help identify and address potential corrosion issues before they escalate, minimizing the risk of unexpected failures. Corrosion can cause equipment failures and operational disruptions. Corrosion protection measures ensure the reliable operation of critical electrical systems.

Regulatory Compliance:

In many industries, regulations and standards are in place that require the use of corrosion protection methods to ensure the safety and reliability of electrical systems. This is why Super CORR A is specified in the maintenance manuals for many aircraft manufacturers. Compliance with these regulations is essential to avoid legal and financial consequences.

Overall, corrosion protection is vital for safeguarding electrical and electronic equipment, reducing costs, ensuring safety, and maintaining the reliability and longevity of critical systems across various industries. Common methods of corrosion protection for electrical systems include the use of corrosion-resistant materials, coatings, sealants, periodic inspections, and maintenance, as well as environmental controls to reduce exposure to corrosive elements. Overall, prioritizing corrosion protection is essential for ensuring the safety, reliability, and longevity of electrical systems.

Specialist Barrier Film Corrosion Protection

EnviroTech Europe supplies advanced corrosion protection products, based on approved synthetic materials, to provide quality solutions to a range of lubrication and corrosion problems.

Super CORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors providing a superior lubrication coefficient and protection against moisture, wear, general and fretting corrosion, static electricity, corona, and other electro migration problems. The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive.

Super CORR A is unexcelled in preventing failures of electrical systems and electronic equipment caused by corrosion as well as preventing the corrosion of metal components surfaces. Use Super CORR A to protect connectors, electrical systems and switches and mechanical controls during servicing. It’s ability to displace water from exposed contacts can ensure reliable operation in extreme conditions, all from one small aerosol can.

The use of Super CORR A for corrosion control can not only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace the damaged equipment or component that failed because of corrosion.

Super CORR A is packaged in aerosol cans making access to component parts easy for engineering crews in difficult locations and conditions. Unpainted mild steel will not rust on exterior surfaces directly exposed to sea water environments for at least 6 months, protecting electrical connectors, switches, chains, drive shafts from corrosion while maintaining lubrication on moving surfaces.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

APPROVED

- Industry approval from: NASA, Boeing Aircraft, Bombardier, Embraer, Lear, Gulfstream, Hawker-Beechcraft, Cessna, Raytheon, Polish Airforce, Northrop-Grumman, Royal Navy and Royal Norwegian Air Force.

- Exceeds Mil C 81309 Corrosion Prevention Compounds.

- Approved in US Tri-Service Corrosion Manuals.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Why are vapour degreasing solvents so good at cleaning?

Why are vapour degreasing solvents so good at cleaning?

Vapour degreasing solvents are typically chosen for their excellent solvency properties. They have the ability to dissolve and disperse a wide range of contaminants, including dirt, oil, grease, wax, and other contaminants. The cleaning action of solvents is primarily attributed to their unique molecular properties and interactions with the materials they contact. Here’s why solvents are so good at cleaning:

Low Surface Tension:

Vapour degreasing solvents can reduce the surface tension of liquids, making them more effective at penetrating and breaking up dirt and stains. This allows the solvent to reach areas that might otherwise be hard to clean.

Polarity:

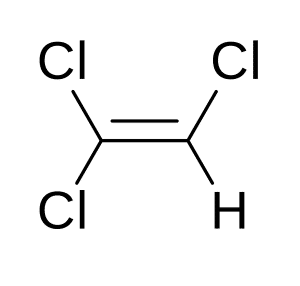

The polarity of a solvent plays a significant role in its cleaning ability. Polar solvents have molecules with positive and negative poles, which allows them to interact with polar substances like water-based stains. Nonpolar solvents, on the other hand, are effective at dissolving nonpolar substances like oils and grease. Different cleaning tasks may require the use of polar or nonpolar solvents depending on the nature of the dirt or stain. Most vapour degreasing solvents are nonpolar in nature, meaning they do not have a positive or negative charge. This allows them to interact with a variety of contaminants, regardless of their charge or polarity, making them versatile for different types of cleaning applications.

Heat and Vaporization:

The vapour degreasing process involves heating the solvent to create vapour, which rises and condenses on the surfaces to be cleaned. This condensation releases latent heat, which aids in loosening and lifting contaminants from the surfaces. The vaporization and condensation cycles help dislodge and carry away dirt, oils, and other substances effectively.

No Aqueous Residues:

Unlike water-based cleaning methods, vapour degreasing solvents leave little to no aqueous residue behind. This is especially important for applications where water could cause corrosion or damage, such as cleaning sensitive electronics or precision mechanical components.

Minimal Agitation Required:

Vapour degreasing is a relatively gentle cleaning method that doesn’t require extensive mechanical agitation. This reduces the risk of damaging delicate parts while ensuring effective cleaning.

Consistency:

Vapour degreasing provides consistent and uniform cleaning results because the solvent vapor can reach all surfaces evenly, including intricate and complex geometries.

Environmental Considerations:

While some vapour degreasing solvents in the past were environmentally concerning, modern solvents are designed to be safer and more environmentally friendly. They are engineered to have lower toxicity, reduced volatility, and minimal global warming or ozone-depleting potential.

Dissolving Power:

Solvents have the ability to dissolve a wide range of substances, both organic and inorganic. This is due to their molecular structure, which allows them to interact with different types of molecules. When a solvent comes into contact with a substance, its molecules surround and separate the particles of the substance, breaking down the intermolecular forces holding them together. This leads to the dissolution of the substance into the solvent.

Evaporation:

Vapour degreasing solvents typically have relatively low boiling points, which means they evaporate quickly when exposed to air. This evaporation helps in removing the dissolved dirt and contaminants from surfaces, leaving them clean and dry. It is important to ensure evaporating solvent doesn’t escape to the atmosphere. This is achieved by having cold condensing coils just above the components being cleaned.

Versatility:

Vapour degreasing solvents come in various types and compositions, allowing them to target specific types of contaminants. For example, alcohol-based solvents are effective at cleaning glass surfaces due to their ability to dissolve and evaporate quickly without leaving streaks.

Chemical Interactions:

Vapour degreasing solvents can undergo chemical reactions with certain types of substances, leading to their removal or transformation. This can be especially useful for removing tough stains that might not be easily removed through simple dissolution.

Compatibility:

Vapour degreasing solvents are often formulated to be compatible with specific materials, ensuring that they don’t damage the surfaces being cleaned. This makes them versatile for use on a wide range of surfaces.

Rinsing Action:

Vapour degreasing solvents can also act as rinsing agents, carrying away dissolved dirt and contaminants when they evaporate. This helps prevent redeposition of dirt onto cleaned surfaces.

Overall, the combination of excellent solvency, low surface tension, nonpolar properties, heat assistance, minimal residue, and controlled vaporization make vapor degreasing solvents highly effective for a wide range of cleaning applications.

It’s important to note that while solvents are effective cleaning agents, their use should be handled with care. Some solvents can be toxic, flammable, or harmful to human health and the environment, so proper precautions and guidelines should be followed when using them. Additionally, choosing the right solvent for a specific cleaning task is crucial to achieve optimal results without causing damage to the surfaces being cleaned.

Zero Ozone Depletion Potential (ODP) and very low Global Warming Potential (GWP) solvent cleaner for high performance vapour degreasing

ProSolv® 5408e has been developed to provide superior critical cleaning performance for manufacturers of electronic and electrical components. High Solvency (KB Value 98) for removal of organic residues, compatible with organic and synthetic oils and most plastics and metals.

ProSolv® 5408e is a high-performance solvent cleaner used for sustainable and future proof vapour degreasing. It has a GWP of less than 1, with a 100 year Integrated Time Horizon (ITH). Soft on the environment and safe for users, it offers improved cleaning at lower costs.

ProSolv® 5408e ticks all the boxes and is the perfect profile for a modern vapour degreasing solvent. Exceptionally low surface tension to penetrate micron sized holes and close contact surfaces. Sustainable and secure for the future. Non-carcinogenic, low boiling point, economical with energy with low solvent losses, faster production, reduced costs, easy handling.

EFFICIENT AND ECONOMICAL

- Fast precision cleaning with short cycle times.

- Can be used in any vapour degreasing equipment, lower energy consumption and lower maintenance.

- Ideal replacement for Trichloroethylene, n-Propyl Bromide, Perchloroethylene and HCFC based solvents.

- Stable with no additives, no testing required.

- Improved productivity, parts exit the machine cool, dry and spot-free with no drying required.

- Minimal non-volatile residue (>10ppm).

- High density solution, excellent for ultrasonic cleaning.

- Mid-range boiling point (46°C).

- Very low surface tension for penetration into the micron level crevices and holes, efficient cleaning in tight to reach places and complex geometries.

- Easy process monitoring with minimal effort and minimal waste generation, easy reclamation for reuse.

- High Solvency (KB Value 98) for a variety of contaminants.

- Compatible with a broad range of substrates.

SAFE FOR USERS AND THE ENVIRONMENT

- Safe for the environment, Zero Ozone Depletion Potential (ODP).

- Very low Global Warming Potential (GWP)

- GWP of less than 1, AR4 100yr Integrated Time Horizon (ITH).

- Non-hazardous for transportation.

- Non-flammable (No Flash Point).

- Not classified as a carcinogen

Listed above are some of the benefits from using ProSolv® 5408e, a sustainable vapour degreasing solvent for precision cleaning and an economical and efficient replacement solution for cleaning systems using older legacy solvents, which are now either banned or being phased out. EnviroTech Europe have many years of experience and our experts are available to guide you through your solvent cleaner changeover procedures or to advise on equipment.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/prosolv5408e for information about other uses and applications for ProSolv 5408e.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

The advantages of using fluorinated solvents

The advantages of using fluorinated solvents for your vapour degreasing process

Fluorinated solvents, also known as fluorocarbon solvents, offer several advantages in various industrial and scientific applications, including being highly suited for vapour degreasing. Here are some of the key advantages of using fluorinated solvents:

Environmental Compatibility:

Fluorinated solvents are often chosen as alternatives to more hazardous solvents due to their relatively low impact on the environment. They have low ozone depletion potential (ODP) and negligible global warming potential (GWP). Additionally, they have low toxicity and are not classified as hazardous air pollutants (HAPs).

Chemical Stability:

Fluorinated solvents exhibit excellent chemical stability, making them highly resistant to degradation and reactions with other chemicals. They are compatible with a wide range of materials, including metals, plastics, and elastomers. This stability allows for their use in challenging environments and with reactive substances.

Solvency Power:

Fluorinated solvents have strong solvency power, meaning they can dissolve a wide range of organic and inorganic compounds. This property makes them effective in applications such as cleaning, degreasing, and precision cleaning, where the complete removal of contaminants is crucial, such as cleaning to oxygen standard.

Nonflammability:

One of the significant advantages of fluorinated solvents is their non-flammable nature. Under testing to ASTM D 93 they will not flash and therefore do not support combustion, making them safer to use compared to many traditional solvents. This property reduces the risk of fire hazards in various industrial processes and applications.

Dielectric Properties:

Fluorinated solvents have excellent dielectric properties, making them ideal for applications that require electrical insulation and heat transfer. They are commonly used in electronic and electrical industries for tasks such as cleaning electrical components, cooling electronics, and as a dielectric fluid in transformers and capacitors.

Thermal Stability:

Fluorinated solvents can withstand a wide range of temperatures without decomposing or losing their properties. This thermal stability allows them to be used in high-temperature applications, including heat transfer fluids, lubricants, and as coolants in various industrial processes.

Surface Tension Control:

Fluorinated solvents have the ability to modify the surface tension of liquids, enabling them to spread evenly and improve wetting. This property makes them useful in applications such as coatings, adhesives, and printing, where uniform and controlled wetting is required.

Zero Ozone Depletion Potential (ODP) and very low Global Warming Potential (GWP) solvent cleaner for high performance vapour degreasing

ProSolv® 5408e has been developed to provide superior critical cleaning performance for manufacturers of electronic and electrical components. High Solvency (KB Value 98) for removal of organic residues, compatible with organic and synthetic oils and most plastics and metals.

ProSolv® 5408e is a high-performance solvent cleaner used for sustainable and future proof vapour degreasing. It has a GWP of less than 1, with a 100 year Integrated Time Horizon (ITH). Soft on the environment and safe for users, it offers improved cleaning at lower costs.

ProSolv® 5408e ticks all the boxes and is the perfect profile for a modern vapour degreasing solvent. Exceptionally low surface tension to penetrate micron sized holes and close contact surfaces. Sustainable and secure for the future. Non-carcinogenic, low boiling point, economical with energy with low solvent losses, faster production, reduced costs, easy handling.

EFFICIENT AND ECONOMICAL

- Fast precision cleaning with short cycle times.

- Can be used in any vapour degreasing equipment, lower energy consumption and lower maintenance.

- Ideal replacement for Trichloroethylene, n-Propyl Bromide, Perchloroethylene and HCFC based solvents.

- Stable with no additives, no testing required.

- Improved productivity, parts exit the machine cool, dry and spot-free with no drying required.

- Minimal non-volatile residue (>10ppm).

- High density solution, excellent for ultrasonic cleaning.

- Mid-range boiling point (46°C).

- Very low surface tension for penetration into the micron level crevices and holes, efficient cleaning in tight to reach places and complex geometries.

- Easy process monitoring with minimal effort and minimal waste generation, easy reclamation for reuse.

- High Solvency (KB Value 98) for a variety of contaminants.

- Compatible with a broad range of substrates.

SAFE FOR USERS AND THE ENVIRONMENT

- Safe for the environment, Zero Ozone Depletion Potential (ODP).

- Very low Global Warming Potential (GWP)

- GWP of less than 1, AR4 100yr Integrated Time Horizon (ITH).

- Non-hazardous for transportation.

- Non-flammable (No Flash Point).

- Not classified as a carcinogen

Listed above are some of the benefits from using ProSolv® 5408e, a sustainable degreasing solvent for precision cleaning and an economical and efficient replacement solution for cleaning systems using older legacy solvents, which are now either banned or being phased out. EnviroTech Europe have many years of experience and our experts are available to guide you through your solvent cleaner changeover procedures or to advise on equipment.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/prosolv5408e for information about other uses and applications for ProSolv 5408e.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Latest News

Eco Friendly Industrial Solvent Cleaners

Solvents used for cleaning must be highly refined and leave no residues on drying. They have to be very effective in removal of oils and soils without causing damage or corrosion of the parts or components being cleaned and leave minimal residues which will be the result of process design. Cleaning to remove process oils and particles can use single or multitank spray washers or immersion tanks with ultrasonics or agitation depending on the volume of components and cleaning specifications. These vary widely from very demanding automotive and aerospace applications to less demanding applications where critical cleaning is not a requirement.

Pre-used parts or assemblies from the transportation, aerospace or manufacturing equipment sectors are often very heavily contaminated when removed from service but must be free of these oils, soils, grease, dirt and contaminants before handling to disassemble prior to refurbishing and rebuilding. Much of this work will be manual and the considerations for the safety of operators, hand wiping or brush cleaning is paramount. Provision of personal protection equipment (PPE) such as gloves, overalls, safety glasses and possibly masks must be carefully considered to be sure the PPEs are compatible with the solvents.

Among other considerations are the working space where the cleaning applications are to be carried out. Flammability versus drying time is always an issue. It is preferable to use a slower drying high flash point solvent in enclosed areas. Good ventilation with a high extraction rate of air will assist drying. In enclosed machines with automatic handling a positive extraction rate of air and heated and extracted final tank can lower process times. Flame proofing requirements and the insurance implications of the faster drying times of more volatile flammable solvents is often mitigated by the use of less volatile, lower VOC materials by design of machines and careful consideration of costs which these solvents offer in lower usage and longer tank life with much lower disposal costs of used materials.

The growing concerns regarding environmental and health hazards of the most commonly used chlorinated solvents for industrial degreasing and cleaning has led to the formulation by EnviroTech Europe of the Clarea range of safer cleaning solvents.

Clarea solvents can be used for spray or immersion cleaning for very heavy soiling or in multitank processes to meet the highest standards demanded for critical cleaning. They can be used as wipe or brush cleaners for large surface areas prior to painting or powder coating.

Why should you choose Clarea industrial cleaning solvents.

The solvents applied during production or finishing processes have a direct effect on the health of workers and the environment. Volatile organic compounds or VOCs are chemicals which vaporise at room temperatures. Traditional solvents used for cleaning have low boiling points and a high VOCs making them harmful to use and less eco-friendly Exposure to the VOC’s released by these cleaning agents must be controlled to prevent respiratory, allergic, and immune system complications for users. If your company uses industrial degreasing agents regularly, it is time to evaluate the implications of this choice.

Clarea is a less volatile alternative than conventional cleaners. Highly refined aliphatic hydrocarbons with minimal residues and tight vaporisation ranges are capable of providing the same results and can be substituted to create a safer, sustainable, eco-friendly workplace. The low odour, low flammability and low toxicity of Clarea solvents provides performance and operator and environmental acceptability using less material at lower costs. Multipurpose use can reduce the inventory of cleaning fluids stocked.

Clarea® HC40 for brush and hand wiping, air dries. Flash point 40℃.

Clarea® HC62 for dip cleaning with agitation or ultrasonics. Low evaporation. Non-flammable.

The Clarea range of solvents is supplied through our distributors worldwide who can supply information on best practice and the best process and equipment to meet your specifications.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Condensation Cleaning

CONTENT ON THIS PAGE IS RETAINED FOR INFORMATION ONLY

DUE TO n-Propyl bromide now being included in Annex 14 of REACH

EnviroTech Europe Ltd (ETE) continue to publish it as historical information and to record changes occurring in legislation which have affected decisions on formulations and equipment used in vapour degreasing - the most effective, quickest, flexible and cheapest cleaning system used in industry.

EnSolv® invented and patented by EnviroTech has been a market leader all over the world for vapour degreasing. It is based on n-bromopropane (nPB) which now cannot be used as a vapour degreaser within the UK or EU without authorisation.

Archived information about EnSolv® can be found using the Discontinued Products & Resources navigation menu on this page.

Using experience accumulated over 40 years supplying and supporting users of the vapour degreasing process ETE specialists have developed “drop in” alternatives:

ProSolv®, ProSolv5408e® and EnSolv CC-A® give the same or improved level of performance and economy as the original EnSolv® products.

Please contact our advisers who are available to discuss your needs and propose the best replacement product.

Or please click here to return to our vapour degreasing products homepage for information about our current products.

The future for solvent vapour degreasing equipment – Innovation driven by legislation.

Vapour degreasing is the simplest but most effective degreasing and cleaning process for industrial use. It has, until recently, been subject to little change since it was first invented in the early part of the last century. The name for the process is a misnomer as the cleaning is achieved by solvent vapour condensing on the cooler target parts the hot liquid solvent dissolving oil and removing dirt.

Vapour degreasing is a mature chemical technology on which legislation is now effecting changes so fundamental that the more accurate name for the process “Condensation Cleaning” should be used to reflect the way in which it works. The open topped tanks so ubiquitous in factories and workshops worldwide are no longer acceptable and the alternatives in equipment design and their fundamental differences in technology which guarantee the continuing use of vapour degreasing in the future need to be considered and understood.

In Europe the United States and in other advanced industrialised economies increasingly stringent legislation to control emissions of VOCs and especially solvents has led to new formulations for paints and other coatings where water replaces most of the solvent. In the early days the quality of the coatings was not as good as solvent based coatings but innovation has driven the development of new polymers with results as good as, if not better than, the solvent based originals.

As with coatings, cleaning systems have had to change. With increased regulation users of solvent have been targeted and alternatives are encouraged by the relevant authorities and law makers often without serious consideration of unintended consequences.

For example water based cleaning is the obvious alternative but this has many disadvantages compared to condensation cleaning as although the machines are simple and relatively cheap the processes require multiple tanks for immersion or spray processing or long programmed cycles in batch machines for cleaning, rinsing and drying. Water based processes are slow, energy intensive and occupy more floor space than condensation cleaning equivalent where only one tank with small footprint is needed delivering shorter process times and most importantly using minimal energy.

The ideal cleaning process would be “Condensation Cleaning” with water but due to the physical characteristics of the water vapour/steam and the inability to carry onto the surface of the targeted parts surfactants to remove the oil, grease and soils and the difficulty of rinsing and especially drying this can only ever be a dream.

A little history of the chemistry helps to explain the changes since the introduction of the vapour degreasing process. Suitable chemicals must be very good solvents for oil, grease, and other industrial soils non-flammable, safe for users and the environment and very stable when heated continuously for long periods.

Halogenated hydrocarbons are the solvents of choice for “Condensation Cleaning”. The process is essentially simple. A tank with a sump to contain the solvent, heaters at the base and condensation coils around the top section to control the height of the vapour is all that is required. When heated in the sump halogenated solvents produce, a saturated vapour between 3 and 4 times heavier than air at a temperature greater than the ambient conditions. This allows the solvent vapour to condense on the surface of the parts to be cleaned. The condensate dissolves the contaminants such as oil, greases and soils returning the used solvent into the sump of the machine for recycling into vapour which continuously condenses onto the parts until they have achieved the same temperature as the solvent vapour when, with no further condensation, the process is complete. Parts removed from the cleaning machines are very clean, warm and dry.

The most common halogenated solvents, in use for commercial purposes, are non-flammable so present no risk in this process. Perchloroethylene, used mainly for dry cleaning, methylene chloride used more widely in paint strippers and trichloroethylene used for vapour degreasing were the original materials used based on chlorine chemistry. However continuing concern about the environmental impact and danger to operators by exposure to chlorine based solvents, especially trichloroethylene, has led to a continuing search for safer alternatives.

1,1,1 trichloroethane (Genklene from ICI and Chlorothene from Dow Chemicals) both of which were based on another chlorinated solvent were to become ubiquitous in the mid part of the last century as a much safer, non- carcinogenic replacement for trichloroethylene. This was an excellent solvent safe for users but which, with increased awareness of the environmental impact of solvents, proved to be depleting the protective ozone layer around the Earth and was subsequently, banned. With the development of the REACH legislation in Europe, which now classifies trichloroethylene as a human carcinogen, usage is allowed but with restrictions and stringent controls for use authorised in machines which control factory emissions to very low figures close to zero.

Meanwhile cleaning solvents based on 1-bromopropane such as EnSolv were developed in the United States as a drop in replacement for trtichloroethane. EnSolv has an identical profile, stable, non-flammable, with the same physical characteristics such as boiling point and specific gravity and it is an excellent cleaning solvent but without the potential for ozone depletion.

During this time new halogenated solvent blends using trans1.2 dichloroethylene, a highly flammable solvent with similar chemistry to trichloroethylene were also developed for condensation cleaning. The trans 1.2 dichloroethylene is blended with a variety of different fluorocarbon solvents which are not suitable as cleaning solvents, as they have very low solvency, but are used in these blends as a fire retardants. An extremely expensive answer to a simple problem, already solved by the development of machines able to safely use the more economical solvents.

As with all legislation for the use of chemicals regulation and restrictions drive development of associated processes and equipment. The most important developments in machines to use solvents for condensation cleaning use two different approaches and raise difficult questions as to which is the best most economical and simplest in use.

Figure 1 – Solvac Automatic hermetically sealed vapour/liquid cleaning system conveyor fed.

The single tank hermetically sealed machines favoured by some equipment manufacturers uses a process tank to contain the solvent and a separate storage tank/vapour generator. Baskets, containing soiled parts, are loaded from the top or through access points on the side of the tank. Lids or doors close over the opening and the process tank is hermetically sealed. Baskets are immersed in solvent, where agitation, ultrasonics or pumped liquid is circulated through the parts.

When the immersion process is completde solvent is removed to the storage tank and vapour fed to the process tank from a vapour generator for rinsing and drying. On completion of the cycle coil,s located within the process tank collapse the vapour. The process tank is evacuated by vacuum and recycled through carbon absorption units to remove traces of solvent from the air until the concentration is below limits set by regulators when the lid opens automatically for the basket of parts, clean and dry, to be safely removed and replaced with a further basket.

Variations of process within the hermetically sealed tank are possible using sprays of cold or hot condensed solvent, immersion with or without ultrasonics and revolving baskets to deal with the problems experienced when processing machined and fabricated parts. Continuous external distillation of the contents of the vapour generator is also an option depending on contamination.

The alternative technology is much simpler and cheaper using well tried techniques not requiring the long recovery times of the hermetically sealed processes. The multilevel system uses a standard vapour degreasing tank design with a sealed loading section above the process tank.

Figure 2 Solvac 1000 – Hermetically sealed multilevel vapour degreasing system for manual load batch processing.

Components, to be cleaned, in baskets or on jigs, are fed to the automated hoist in the load section manually, by hoist or conveyor. The loading door is sealed pneumatically to completely isolate the process. The process tank sealing lid opens and the basket lowered into the process chamber. Depending on the soils simple condensation cleaning can be used or with the lower section being filled with clean solvent for immersion cleaning with or without ultrasonics or power sprays. Revolving baskets are a further option to improve cleaning in blind or through holes or oil ways in castings and fabrications.

With the process completed the basket rises to the freeboard area where the condensation coils are located and parts allowed to drain and dry. The tank seal opens to allow the basket into the load section while the lid closes to seal the process tank. A fan is then activated which produces a negative vacuum in the load area. The loading door partially opens to allow a flow of air through the loading section which is exhausted to atmosphere or can be recycled through carbon absorption systems.

As baskets entering the loading space contain parts drained and dried only very small amounts of solvent are carried in the exhausted air which is monitored to ensure compliance with appropriate legislation. When this is completed the door opens fully for removal of cleaned components. The loading section can be fitted with top or side sealed doors allowing baskets to flow through on conveyor systems or be loaded from hoists. No solvent enters the work area.

Both processes will produce parts cleaned to the highest standards but the choice of which offers the best solution needs a little more consideration.

The hermetically sealed vacuum process is complicated with the need to move liquids in the machine. It is relatively slow as the carbon adsorption process needs to remove high levels of solvent from the recirculated airstream from the process tank. This is inefficient as adsorption rates for carbon fall rapidly with increasing saturation. Final levels of solvent in the tank when the lid or loading door opens will be emmited into the workspace and the area in which the operator is working. Long process cycles reduce throughput.

The simpler multilevel systems where movement of liquids is not required are more efficient and offer much faster process times. Cost of manufacture is also lower as no liquid movement or vacuum is involved. The extracted loading section ensures no leakage of solvent into the work area which gives complete safety for operators and factory staff. The disadvantage of the multilevel machine is the height of the equipment compared to the hermetically sealed machine. This will often need the equipment be installed in a pit for easy access.

Both designs of process machines fully comply with the emission regulations of the EU and U.S authorities. Which to choose will depend on many factors which should be discussed with both the equipment and solvent suppliers who have the experience to advise on which offers the best process for the application. Equipment and solvent work together as a process and it is essential to ensure that the suppliers work closely together to offer a package with high levels of responsible care and product stewardship to ensure the best results and safest installation.

The “Condensation cleaning” process still gives the highest levels of economical cleaning with minimum energy usage, low footprint on the factory floor, safety for the operator, and high production rates with low solvent usage or environmental impact. With the new generation of sealed cleaning machines its future as the process of choice for industrial cleaning is assured.

EnSolv cleaning solvents are supplied throughout Europe.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Reduce Corrosion Fretting

Why use of SuperCORR A for maintenance of electrical connections on Gas Turbines improves performance by reducing corrosion fretting.

LP Gas Turbines are used throughout the world by extraction industries and manufacturing plants in remote and hostile locations for essential power production. Dusty and wet environments in deserts, mines, grinding mills, pulp and paper mills and on land or sea drilling rigs for gas and oil production. Turbines powering aircraft services while stationary connect and disconnect many times a day in extreme conditions. These applications and locations test connector sealing continuously allowing dust or water to penetrate. This with the flexing of the connecting cables allows sufficient movement between the metal surfaces of the connecting pins to produce fretting corrosion which reduces, interrupts or produces failures in supply.

Regular maintenance of electrical connectors is essential to be certain of uninterrupted supply.

SuperCORR A is an aerosol lubricant containing corrosion preventive compounds, and, as is the case with all lubricants, they can be worn off over time. A manufacturer of connectors tested SuperCORR A to see what the “life” of the lubricant was in a “rub test”. The typical test is 20,000 cycles, i.e. unplug, plug in is one cycle. The test results demonstrated that after 20,000 cycles there were no failures. It was decided to take it one more step and run the same tests for 200,000 cycles. The results again showed no indications of galling or scoring on the connectors at all. The connector looked and tested as good as new. This test

was run under clean conditions in a laboratory but demonstrates the effectiveness of the protective lubricant in SuperCORR A.

As it meets Mil-DLT-87177B specifications it is used by the U.S. Air Force to protect the intricate workings of the F-16 and F-15 fighter jets and by the U.S. Navy on the P 3 Orion electronic surveillance aircraft. Savings for the U.S. government is estimated at $50 million per year. Commercial Aviation aircraft manufacturers recommend it for avionics and electrical switches and connectors and close mechanical application, especially where flights are in salt fog or high humidity.

Containing extremely long-lasting, proprietary anti-corrosive inhibitors SuperCORR A provides a superior lubrication coefficient and protects components against moisture, wear, general and fretting corrosion, surface static electricity, corona, and other electro migration problems. The super thin non-flammable lubricant film is only 7 microns (0.0007 inch) thick and is formulated without sulphates, chlorides or halogens to meet the RoHS directive. It is unexcelled in preventing deterioration and contamination on all surfaces of electronic equipment.

Very fast drying environmentally acceptable solvents are used as carriers and propellants which will not affect most plastics, substrates, metals or other materials used in connector manufacture. The aerosols are supplied with probes which allow access to pins and connector tubes where the low surface tension repels water, dirt dust and metal particles from blind holes and surfaces to produce thoroughly clean holes and surfaces before a second application applies the lubricant film. Reconnection to the supply with cleaned sections of the connector ensures reliable operation even in the most testing of environments. This easy maintenance from one can of SuperCORR A allows this essential task to be carried out in any conditions quickly, easily and securely.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Managing “false alarms” and “no fault found” events in Military avionic systems.

Paper presented at the recent 2017 Aviation Electronics Europe Expo in Munich by Dr. Mustafa Ilarslan, PhD.

In a paper presented at the recent 2017 Aviation Electronics Europe Expo in Munich, Germany, Dr. Mustafa Ilarslan, PhD, discussed – “The management of “False Alarms” and “No Fault Found” events in Military avionic systems”.

In his paper Dr. Ilarslan explains that “False alarms (FAs) impose a devastating impact on military systems. An entire aircraft can be grounded because of a single avionics for which there are insufficient spares available. If a FA causes a particular Line Replaceable Unit (LRU) to be called out incorrectly, there is a better than even probability that a second copy of the same LRU will also experience FA and much sooner than expected, the fleet will be deprived of all spares for that LRU. To then find that the LRUs replaced had No Fault Found (NFF) at the repair depot adds “salt to the wound.” while adding huge sums for lost time in servicing, aircraft downtime and unnecessarily high stocks of replacement parts.

SuperCORR A was designed specifically to prevent these problems in avionic as well as electrical and electronic components and systems failures caused by corrosion, including no fault found failures and problems caused by Cadmium corrosion. SuperCORR A is a proprietary Ultra-Thin Film, Water Displacing Lubricant and Corrosion Preventative Compound, manufactured under license in the UK by EnviroTech Europe Ltd.

SuperCORR A is being used on both military and civilian aircraft to prevent fretting corrosion on electronic and electrical connectors, including F-16, P-3 Orion, Boeing 737’s, C-130, F-15, DHC-6 Twin Otter, Bell helicopters, Bombardier BD-700 series and Bombardier Challenger 300/350, Learjet 45, Legacy 650, and Hawker to name but a few.

SuperCORR A is also being used at BAE Systems, Honeywell and Raytheon Systems to prevent corrosion from causing avionic, electronics, and electrical systems and components failures and for lubrication and protection of moving parts with a thin dry film.

SuperCORR A meets the requirements of MIL-L-87177A and Mil-DTL-87177B.

More detailed information can be found in the paper “Electrical connector corrosion prevention Improves reliability and reduces costs” by David Horne which is available here:

NOTE that while quoting Dr. Ilarslam’s paper, with his permission, he is not endorsing or recommending the use of any specific product, including SuperCORR A.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Vapour Degreasing Solvents For Precision Metal Cleaning

CONTENT ON THIS PAGE IS RETAINED FOR INFORMATION ONLY

DUE TO n-Propyl bromide now being included in Annex 14 of REACH

EnviroTech Europe Ltd (ETE) continue to publish it as historical information and to record changes occurring in legislation which have affected decisions on formulations and equipment used in vapour degreasing - the most effective, quickest, flexible and cheapest cleaning system used in industry.

EnSolv® invented and patented by EnviroTech has been a market leader all over the world for vapour degreasing. It is based on n-bromopropane (nPB) which now cannot be used as a vapour degreaser within the UK or EU without authorisation.

Archived information about EnSolv® can be found using the Discontinued Products & Resources navigation menu on this page.

Using experience accumulated over 40 years supplying and supporting users of the vapour degreasing process ETE specialists have developed “drop in” alternatives:

ProSolv®, ProSolv5408e® and EnSolv CC-A® give the same or improved level of performance and economy as the original EnSolv® products.

Please contact our advisers who are available to discuss your needs and propose the best replacement product.

Or please click here to return to our vapour degreasing products homepage for information about our current products.

Environmentally friendly precision vapour degreasing and cleaning solvents for the aerospace, precision engineering, medical, optical and electronic industries.

EnSolv vapour degreasing solvents are the most effective alternative to trichloroethylene and other chlorinated and fluorocarbon based solvents. Fast, economical cleaning and degreasing in one tank using minimal floor area.

EnSolv degreasing solvents are specifically formulated to address the difficult precision cleaning problems experienced in high-tech industries where exceptional levels of cleanliness are needed.

EnSolv is a trusted family of environmentally friendly precision vapour degreasing and cleaning solvents for the aerospace, precision engineering, medical, optical and electronic industries. Custom blends serve applications where standard formulations require modifications.

These degreasing solvents are specifically formulated to address the difficult cleaning problems experienced in industries where exceptional levels of precision cleaning are needed.

The EnSolv range of solvents are economical in use, with very high solvency power for excellent fast precision cleaning in any vapour degreasing equipment with greatly improved productivity and lower maintenance costs. Mid range operating temperature reduces energy usage with a faster cleaning cycle and easier more comfortable handling for operators.

EnSolv is safe for the environment with low global warming and ozone depletion the lower temperature of operation reduces energy usage and reduces CO2 emission. EnSolv® is not classified as a carcinogen enhancing safe usage for operators

EnSolv is approved by US EPA Snap and is included in US Tri- Service corrosion manuals. Usage is Approved by Boeing and the major OEMs worldwide as a replacement for trichloroethylene.

Manufactured in the UK with excellent customer service, technical support and training from qualified distributors throughout Europe.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Industrial Degreasing Solvents – Safe For The Environment

Eco Friendly Industrial Degreasing Solvents, Safe For Users And The Environment.

Cleaning agents are used in many industries to remove dirt, oil, grease, or other contaminants from machined and fabricated metal, plastic and composite surfaces.

The solvents must be highly refined and leave no residues on drying. They have to be very effective in removal of oils and soils without causing harm to the parts or components being cleaned and leave minimal residues. Solvents are used for cleaning using spray washers or immersion tanks with or without ultrasonics or agitation in manufacturing or automotive industries for removal of process oils from manufacturing processes .

Pre-used parts or assemblies from the transportation, aerospace or manufacturing equipment sectors are often very heavily contaminated when removed from service but must be free of these oils, soils, grease, dirt and contaminants before handling to disassemble prior to refurbishing and rebuilding.

A growing concern regarding environmental and health hazards of the most commonly used chlorinated solvents as industrial degreasing agents has led to the formulation by EnviroTech Surface Technologies of the Clarea® range of safer cleaning solvents.

Clarea solvents can be used for spray or immersion cleaning for very heavy soiling or are used as wipe cleaners for large surface areas prior to painting or powder coating.

Why should you choose Clarea industrial cleaning solvents.

The solvents applied during production or finishing processes have a direct effect on the health of workers and the environment.

Volatile organic compounds or VOCs are chemicals which vaporise at room temperatures. Traditional solvents used for cleaning have low boiling points and a high VOCs making them harmful to use and less eco-friendly Exposure to the VOC’s released by these cleaning agents must be controlled to prevent respiratory, allergic, and immune system complications for users. If your company uses industrial degreasing agents regularly, it is time to evaluate the dangers of this choice.

Clarea is a less volatile alternative than conventional cleaners. Highly refined aliphatic hydrocarbons with minimal residues and tight vaporisation ranges are capable of providing the same results and can be substituted to create a safer, sustainable, eco-friendly workplace.

The low odour, low flammability and low toxicity of Clarea® solvents provides performance and operator and environmental acceptability using less material at lower costs. Multipurpose use can reduce the inventory of cleaning fluids stocked.

Clareaa HC40 for brush and hand wiping, air dries. Flash point 40℃.

Clarea HC62 for dip cleaning with agitation or ultrasonics.

Low evaporation. Non-flammable.

Clarea® range of solvents is supplied through our distributors worldwide.

Other solvents in our cleaning specialities range are:

ProSolv 5408e: Precision solvent for electronics, medical and other critical cleaning applications.

Aquus CL-One: Water based neutral cleaners for use where solvents are not compatible with substrates.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Preventing hydrogen sulphide corrosion in electrical and electronic equipment

A Cost Effective and Proven Corrosion Preventative Solution.

By Larry Clark, EnviroTech Europe Ltd

Electrical and electronic equipment and components that are used in adverse work environments, e.g. the oil and gas industry, waste water treatment plants, and the pulp and paper industry, where corrosive gases such as hydrogen sulphide are found cause severe corrosion and the rapid deterioration of the electronic components and equipment including connectors and switches used in these and other work environments. One economical way to prevent or inhibit corrosion from destroying electronics and electrical components is to use SuperCORR A, Ultra Thin Film, Water Displacing, Lubricant and Corrosion Inhibiting Compound.

If you or your company aren’t worried about costs then by default you aren’t concerned about corrosion or it’s associated costs in lost productivity and lost revenue caused by plant and equipment down time then this a paper that you should just skip. But if you and your company are concerned about costs including the amount money and man hours to repair or replace components to keep an electrical system or electronics operating, an aircraft flying, or a machine running because of failures caused by corrosion then this paper is for you!

Corrosion, in its many forms, is costing both private and public sector hundreds of billions of Euros a year! While all metals corrode due to a number of different factors there is no simple or single solution to the overall corrosion problem. However there are some very cost effective and proven ways to prevent corrosion and failures caused by corrosion and thereby reducing or eliminating associated costs and increasing safety which should be foremost in the mind set of any Preventative Maintenance Programme manager.

One proven and cost effective solution to the corrosion problem is SuperCORR A, a water displacing, ultra thin film lubricant with corrosion preventative properties. SuperCORR A was designed specifically to lubricate and prevent corrosion in electrical fittings and connectors; electrical and avionic harness assemblies and connectors; electrical and electronic switches; close tolerance and dissimilar metal components; lighting connectors and sockets; and the list goes on and on.

SuperCORR A is a unique non-flammable “self healing” ultra thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack. SuperCORR A is not a wax or oil based product and is formulated without sulphates, chlorides or halogens.

SuperCORR A inhibits corrosion caused by exposure to both fresh and salt water moisture as well as the corrosive vapours from Sulphur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulphide (H2S), Ammonia (NH3), and Chlorine (CL12) based gases found in waste water and sewer treatment plants, pulp and paper mills and plants, chemical and petroleum plants, maritime industry, aircraft/airline industry, military equipment including ships, aircraft, and rolling stock, auto industry, farming and agriculture industry, and the list goes on. Extending the working life of electrical components and systems and other critical items by preventing the deterioration and/or failure caused by corrosion can significantly reduce downtime and operating and maintenance costs as well as enhance safety.

The question for you is: What is the cost of NOT using SuperCORR A in your Preventative Maintenance Programme?

SuperCORR A is available from EnviroTech Europe Ltd and our distributors worldwide.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Trichloroethylene a known human carcinogen

CONTENT ON THIS PAGE IS RETAINED FOR INFORMATION ONLY

DUE TO n-Propyl bromide now being included in Annex 14 of REACH

EnviroTech Europe Ltd (ETE) continue to publish it as historical information and to record changes occurring in legislation which have affected decisions on formulations and equipment used in vapour degreasing - the most effective, quickest, flexible and cheapest cleaning system used in industry.

EnSolv® invented and patented by EnviroTech has been a market leader all over the world for vapour degreasing. It is based on n-bromopropane (nPB) which now cannot be used as a vapour degreaser within the UK or EU without authorisation.

Archived information about EnSolv® can be found using the Discontinued Products & Resources navigation menu on this page.

Using experience accumulated over 40 years supplying and supporting users of the vapour degreasing process ETE specialists have developed “drop in” alternatives:

ProSolv®, ProSolv5408e® and EnSolv CC-A® give the same or improved level of performance and economy as the original EnSolv® products.

Please contact our advisers who are available to discuss your needs and propose the best replacement product.

Or please click here to return to our vapour degreasing products homepage for information about our current products.

Trichloroethylene formally listed as a “Known Human Carcinogen”.

|

After many years of being listed as a possible or probable human carcinogen, the widely used solvent trichloroethylene (TCE) has now been listed by the National Toxicology Program (NTP) of the U.S. Department of Health and Human Services as a “known human carcinogen.” Ref; NTP’s 14th Report on Carcinogens (November 3, 2016).

Trichloroethylene is widely used in manufacturing industries as a vapour degreasing solvent but its principal uses are as an intermediate raw material in hydrofluorocarbon chemical manufacture. In the light of a number of human studies showing a causal connection between TCE exposure and an increased risk of kidney cancer, NTP re-evaluated and ultimately reclassified TCE. In addition to cancer risk, other problems that have been attributed to TCE exposure include immunotoxicity, neurotoxicity, reproductive toxicity and developmental toxicity, such as potential fetal cardiac defects.

As a known carcinogen exposure to TCE is highly regulated already in the European Union. From April 2016 its use has required authorisation for specified applications.

The ban on the use of TCE for vapour degreasing, a very widely used cleaning process, causes many problems in the engineering and manufacturing industries where oil and soils need to be removed between stages in the production processes and on finished products. The use of alternative water based cleaners are inconvenient and increase process times and costs.

A safer alternative, EnSolv is available as an established “drop in” replacement for TCE often using existing vapour degreasing equipment. For more information on conversion, help or advice from EnviroTech Europe Specialist team go to www.vapour-degreasing.com.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page: