Latest Articles

Industrial Degreasing Solvents – Safe For The Environment

Eco Friendly Industrial Degreasing Solvents, Safe For Users And The Environment.

Cleaning agents are used in many industries to remove dirt, oil, grease, or other contaminants from machined and fabricated metal, plastic and composite surfaces.

The solvents must be highly refined and leave no residues on drying. They have to be very effective in removal of oils and soils without causing harm to the parts or components being cleaned and leave minimal residues. Solvents are used for cleaning using spray washers or immersion tanks with or without ultrasonics or agitation in manufacturing or automotive industries for removal of process oils from manufacturing processes .

Pre-used parts or assemblies from the transportation, aerospace or manufacturing equipment sectors are often very heavily contaminated when removed from service but must be free of these oils, soils, grease, dirt and contaminants before handling to disassemble prior to refurbishing and rebuilding.

A growing concern regarding environmental and health hazards of the most commonly used chlorinated solvents as industrial degreasing agents has led to the formulation by EnviroTech Surface Technologies of the Clarea® range of safer cleaning solvents.

Clarea solvents can be used for spray or immersion cleaning for very heavy soiling or are used as wipe cleaners for large surface areas prior to painting or powder coating.

Why should you choose Clarea industrial cleaning solvents.

The solvents applied during production or finishing processes have a direct effect on the health of workers and the environment.

Volatile organic compounds or VOCs are chemicals which vaporise at room temperatures. Traditional solvents used for cleaning have low boiling points and a high VOCs making them harmful to use and less eco-friendly Exposure to the VOC’s released by these cleaning agents must be controlled to prevent respiratory, allergic, and immune system complications for users. If your company uses industrial degreasing agents regularly, it is time to evaluate the dangers of this choice.

Clarea is a less volatile alternative than conventional cleaners. Highly refined aliphatic hydrocarbons with minimal residues and tight vaporisation ranges are capable of providing the same results and can be substituted to create a safer, sustainable, eco-friendly workplace.

The low odour, low flammability and low toxicity of Clarea® solvents provides performance and operator and environmental acceptability using less material at lower costs. Multipurpose use can reduce the inventory of cleaning fluids stocked.

Clareaa HC40 for brush and hand wiping, air dries. Flash point 40℃.

Clarea HC62 for dip cleaning with agitation or ultrasonics.

Low evaporation. Non-flammable.

Clarea® range of solvents is supplied through our distributors worldwide.

Other solvents in our cleaning specialities range are:

ProSolv 5408e: Precision solvent for electronics, medical and other critical cleaning applications.

Aquus CL-One: Water based neutral cleaners for use where solvents are not compatible with substrates.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Preventing hydrogen sulphide corrosion in electrical and electronic equipment

A Cost Effective and Proven Corrosion Preventative Solution.

By Larry Clark, EnviroTech Europe Ltd

Electrical and electronic equipment and components that are used in adverse work environments, e.g. the oil and gas industry, waste water treatment plants, and the pulp and paper industry, where corrosive gases such as hydrogen sulphide are found cause severe corrosion and the rapid deterioration of the electronic components and equipment including connectors and switches used in these and other work environments. One economical way to prevent or inhibit corrosion from destroying electronics and electrical components is to use SuperCORR A, Ultra Thin Film, Water Displacing, Lubricant and Corrosion Inhibiting Compound.

If you or your company aren’t worried about costs then by default you aren’t concerned about corrosion or it’s associated costs in lost productivity and lost revenue caused by plant and equipment down time then this a paper that you should just skip. But if you and your company are concerned about costs including the amount money and man hours to repair or replace components to keep an electrical system or electronics operating, an aircraft flying, or a machine running because of failures caused by corrosion then this paper is for you!

Corrosion, in its many forms, is costing both private and public sector hundreds of billions of Euros a year! While all metals corrode due to a number of different factors there is no simple or single solution to the overall corrosion problem. However there are some very cost effective and proven ways to prevent corrosion and failures caused by corrosion and thereby reducing or eliminating associated costs and increasing safety which should be foremost in the mind set of any Preventative Maintenance Programme manager.

One proven and cost effective solution to the corrosion problem is SuperCORR A, a water displacing, ultra thin film lubricant with corrosion preventative properties. SuperCORR A was designed specifically to lubricate and prevent corrosion in electrical fittings and connectors; electrical and avionic harness assemblies and connectors; electrical and electronic switches; close tolerance and dissimilar metal components; lighting connectors and sockets; and the list goes on and on.

SuperCORR A is a unique non-flammable “self healing” ultra thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack. SuperCORR A is not a wax or oil based product and is formulated without sulphates, chlorides or halogens.

SuperCORR A inhibits corrosion caused by exposure to both fresh and salt water moisture as well as the corrosive vapours from Sulphur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulphide (H2S), Ammonia (NH3), and Chlorine (CL12) based gases found in waste water and sewer treatment plants, pulp and paper mills and plants, chemical and petroleum plants, maritime industry, aircraft/airline industry, military equipment including ships, aircraft, and rolling stock, auto industry, farming and agriculture industry, and the list goes on. Extending the working life of electrical components and systems and other critical items by preventing the deterioration and/or failure caused by corrosion can significantly reduce downtime and operating and maintenance costs as well as enhance safety.

The question for you is: What is the cost of NOT using SuperCORR A in your Preventative Maintenance Programme?

SuperCORR A is available from EnviroTech Europe Ltd and our distributors worldwide.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Trichloroethylene a known human carcinogen

CONTENT ON THIS PAGE IS RETAINED FOR INFORMATION ONLY

DUE TO n-Propyl bromide now being included in Annex 14 of REACH

EnviroTech Europe Ltd (ETE) continue to publish it as historical information and to record changes occurring in legislation which have affected decisions on formulations and equipment used in vapour degreasing - the most effective, quickest, flexible and cheapest cleaning system used in industry.

EnSolv® invented and patented by EnviroTech has been a market leader all over the world for vapour degreasing. It is based on n-bromopropane (nPB) which now cannot be used as a vapour degreaser within the UK or EU without authorisation.

Archived information about EnSolv® can be found using the Discontinued Products & Resources navigation menu on this page.

Using experience accumulated over 40 years supplying and supporting users of the vapour degreasing process ETE specialists have developed “drop in” alternatives:

ProSolv®, ProSolv5408e® and EnSolv CC-A® give the same or improved level of performance and economy as the original EnSolv® products.

Please contact our advisers who are available to discuss your needs and propose the best replacement product.

Or please click here to return to our vapour degreasing products homepage for information about our current products.

Trichloroethylene formally listed as a “Known Human Carcinogen”.

|

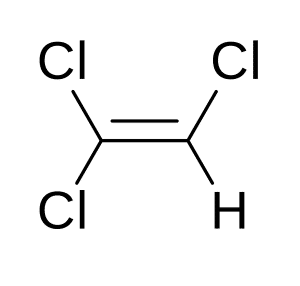

After many years of being listed as a possible or probable human carcinogen, the widely used solvent trichloroethylene (TCE) has now been listed by the National Toxicology Program (NTP) of the U.S. Department of Health and Human Services as a “known human carcinogen.” Ref; NTP’s 14th Report on Carcinogens (November 3, 2016).

Trichloroethylene is widely used in manufacturing industries as a vapour degreasing solvent but its principal uses are as an intermediate raw material in hydrofluorocarbon chemical manufacture. In the light of a number of human studies showing a causal connection between TCE exposure and an increased risk of kidney cancer, NTP re-evaluated and ultimately reclassified TCE. In addition to cancer risk, other problems that have been attributed to TCE exposure include immunotoxicity, neurotoxicity, reproductive toxicity and developmental toxicity, such as potential fetal cardiac defects.

As a known carcinogen exposure to TCE is highly regulated already in the European Union. From April 2016 its use has required authorisation for specified applications.

The ban on the use of TCE for vapour degreasing, a very widely used cleaning process, causes many problems in the engineering and manufacturing industries where oil and soils need to be removed between stages in the production processes and on finished products. The use of alternative water based cleaners are inconvenient and increase process times and costs.

A safer alternative, EnSolv is available as an established “drop in” replacement for TCE often using existing vapour degreasing equipment. For more information on conversion, help or advice from EnviroTech Europe Specialist team go to www.vapour-degreasing.com.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Latest News

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.