Latest Articles

Alternatives to 3M™ Novec™ Engineered Fluids

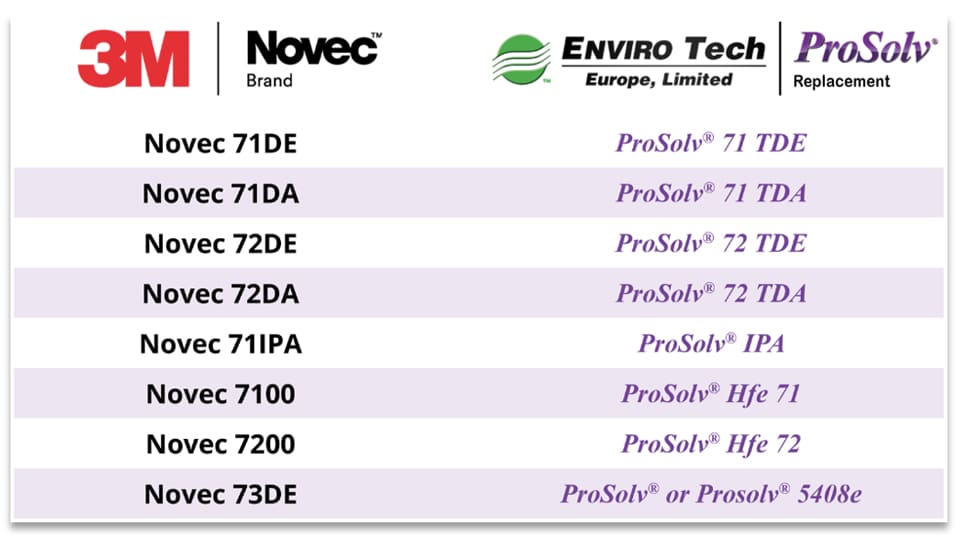

A range of premium quality drop-in alternatives to 3M™ Novec™ Engineered Fluids from EnviroTech Europe

In December 2022, 3M™ announced their plans to stop producing per- and polyfluoroalkyl substances (PFAS) in its product line by the end of 2025.

This phase-out affects the following 3M™ product lines:

3M™ Novec™ Engineered Fluids

3M™ Fluorinert™ Electronic Liquids

ARE YOU AFFECTED BY THE PHASE-OUT OF 3M™ NOVEC™ ENGINEERED FLUIDS?

EnviroTech Europe now offers alternatives to all 3M™ Novec™ solvent cleaning fluids with our ProSolv® range. We understand the uniqueness of every precision cleaning application and provide free on-site visits, technical support and cleaning trials when required.

We can provide a full assessment of your current precision cleaning process to put in a plan to help ensure a seamless transition.

FUTURE-PROOF YOUR CLEANING PROCESS WITH OUR ProSolv® RANGE OF ALTERNATIVES

We have added several cost effective and efficient precision cleaning process formulations to our range of ProSolv® vapour degreasing solvents, offering immediate drop-in alternatives to 3M™ Novec™ engineered fluids.

WHY ACT NOW?

The 3M™ Novec™ range of engineered fluids could soon potentially face shortages and 3M™ distributors world-wide could be struggling to fulfil orders as we get closer to 2025. Some of the 3M™ Novec™ grades will start to become unavailable, others with long lead times and inflated prices as stocks diminish. Envirotech Europe provides chemically exact drop-in alternatives to 3M™ Novec™ engineered fluids, under our ProSolv® range. We will continue to supply this range well after 3M™ leave the market, providing you with peace of mind and control over your supply. Our products are supported by technical experts in the precision cleaning sector we offer our full guidance to keep your precision cleaning process running smoothly.

EnviroTech Europe recommends that customers start the transition as soon as possible to avoid any potential disruption. As well as supplying 3M™ Novec™ drop-in alternatives, Envirotech Europe supply a new generation of PFAS-free cleaning chemistries to future proof your process for many years to come, such as our world-renowned ProSolv®5408e vapour degreasing solvent, which is already widely used across an array of sectors. Envirotech Europe follows up closely on all regulations around the world and are able anticipate well in advance on any changes, to keep you one step ahead. We provide free of charge consultation visits to help your site transition from the 3M™ Novec™ grades. Book your visit now and let us help you keep your critical cleaning process running smoothly with the UK’s leading supplier of precision cleaning chemistries.

FURTHER INFORMATION

Please visit www.envirotech-europe.com/vapour-degreasing-solvents/replace-3m-novec-engineered-fluids/

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Next-generation PFAS-Free solvent cleaners – Championing Change Through Innovation

Next-generation PFAS-Free solvent cleaners – Championing Change through innovation

Vapour degreasing, with or with-out ultrasonics, is the oldest, simplest and most effective solvent degreasing and metal cleaning process used today. It has until recently been subject to little change since it was first invented in the early part of the last century. In the UK, Europe, United States and other advanced economies, increasingly stringent legislation has been put in place to control emissions of VOCs (Volatile Organic Compounds), Global Warming Compounds, Ozone Depleting Compounds and those compounds associated with human health concerns such as PFAS chemicals. This has led to new formulations being developed for solvent cleaners.

The vapour cleaning process still gives the highest levels of economical cleaning with minimum energy usage, low footprint on the factory floor, safety for the operator, and high production rates, with low solvent usage and low environmental impact. With the new generation of sealed cleaning machines its future as the process of choice is assured. Recent regulations on the control of PFAS (Per- and polyfluoroalkyl substances) have resulted in the clamping down on solvents with a high GWP (Global Warming Potential).

Envirotech Europe supplies a next generation vapour degreasing solvent formulation called ProSolv®5408e, with zero Ozone Depletion Potential (ODP) and a Global Warming Potential (GWP) of less than 1, making it safe for operators and kind on the environment. For anyone using solvents with high HFC / HFE such as the soon to be phased out 3M™ Novec™ range, we have direct replacements available.

Advanced vapour degreasing solvent with zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP)

ProSolv®5408e has been developed to provide superior critical cleaning performance, suitable for many different industries. High Solvency (KB Value 98) for removal of organic residue and oils, compatible with organic and synthetic oils and most plastics and metals.

ProSolv®5408e ticks all the boxes and is the perfect profile for a modern degreasing solvent. Exceptionally low surface tension to penetrate micron sized holes and close contact surfaces. Sustainable and secure for the future. Non-carcinogenic, low boiling point, economical with energy with low solvent losses, faster production, reduced costs, easy handling.

ProSolv®5408e can be used in most solvent cleaning systems, vapour degreasing or multi tank immersion / systems using ultrasonics. Also suitable for flushing of complex mechanical and electronic components with blind holes and channels.

ProSolv®5408e has a unique formulation making it PFAS-free, ensuring that your process falls within environmental legislation considerations.

SAFE FOR USERS AND THE ENVIRONMENT

- PFAS Exempt

- GWP of less than 1

- Non-hazardous for transportation.

- Non-flammable (No Flash Point).

- Not classified as a carcinogen.

- RoHS compliant.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/prosolv5408e for information about other uses and applications for ProSolv®5408e.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Electrical corrosion protection – Prevent hydrogen sulphide corrosion in electrical and electronic equipment

Electrical corrosion protection - Prevent hydrogen sulphide corrosion in electrical and electronic equipment

Corrosion in its many forms, costs both private and public sectors hundreds of billions a year to repair or replace electrical, electronics, or avionic components because of failures caused by corrosion. Lost productivity and revenue caused by plant and equipment corrosion is a serious matter. While all metals corrode, due to a number of different factors, there is no simple or single solution to the overall corrosion problem. However there are some very cost effective and proven ways to prevent corrosion and failures caused by corrosion and thereby reducing or eliminating associated costs and increasing safety which should be foremost in the mind set of any preventative maintenance programme.

Electrical and electronic equipment and components that are used in adverse environments, e.g. the oil and gas industry, waste-water treatment plants and the pulp and paper industry, where corrosive gases such as hydrogen sulphide can be found, cause severe corrosion and the rapid deterioration of the electronic components and equipment including connectors and switches used in these and other work environments. Preventing hydrogen sulphide (H2S) corrosion in electrical and electronic equipment involves a combination of preventive measures and material selection. Here are some steps to mitigate H2S corrosion:

Protective Coatings:

An essential corrosion preventative measure is to apply coatings to vulnerable components. One such coating is Super CORR A advanced lubricant and corrosion inhibiting compound. It will help prevent H2S corrosion in electrical and electronic equipment, ensuring their longevity and reliability in environments where H2S exposure is a concern.

Material Selection:

Choose materials that are resistant to H2S corrosion. For example, stainless steel, nickel alloys, and certain plastics are less susceptible to corrosion by H2S compared to carbon steel.

Enclosures, Sealing and Ventilation:

Seal electrical and electronic equipment and cables in airtight enclosures to prevent H2S exposure. Ensure these enclosures are made from corrosion-resistant materials. Implement ventilation systems to reduce the concentration of H2S in the equipment’s environment.

Monitoring and maintenance::

Regularly monitor H2S levels in the environment where the equipment is installed. Install gas detectors to provide early warnings of increased H2S concentrations. Perform regular maintenance checks on equipment to detect any signs of corrosion. Replace any corroded components promptly.

Design Considerations:

Consider the design of the equipment and its surroundings to minimize the likelihood of H2S exposure. For example, elevating equipment above potential H2S sources can reduce corrosion risk.

Education and Training:

Provide education and training to personnel working with the equipment on the risks of H2S corrosion and the importance of preventive measures.

Emergency Response Plan:

Develop an emergency response plan in case of H2S exposure or equipment failure due to corrosion. This plan should include procedures for evacuating personnel and shutting down equipment safely.

SuperCORR A Specialist Barrier Film Corrosion Protection

EnviroTech Europe supplies advanced corrosion protection products, based on approved synthetic materials, to provide quality solutions to a diverse range of lubrication and corrosion problems.

Super CORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors providing a superior lubrication coefficient and protection against moisture, wear, general and fretting corrosion, static electricity, corona, and other electro migration problems. The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive.

The use of Super CORR A for corrosion protection can not only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace the damaged equipment or component that failed because of corrosion.

Super CORR A is a proven and cost-effective way to prevent or inhibit corrosion from destroying electronics and electrical components. It was specifically designed to lubricate and prevent corrosion in electrical fittings and connectors; electrical and avionic harness assemblies and connectors; electrical and electronic switches; close tolerance and dissimilar metal components; lighting connectors and sockets. A unique non-flammable “self-healing” ultra-thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack, is not a wax or oil-based product and is formulated without sulphates, chlorides or halogens.

Super CORR A also inhibits corrosion caused by exposure to both fresh and salt water moisture as well as the corrosive vapours from Sulphur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulphide (H2S), Ammonia (NH3), and Chlorine (CL12) based gases found in waste water and sewer treatment plants, pulp and paper mills and plants, chemical and petroleum plants, maritime industry, aircraft/airline industry, military equipment including ships, aircraft, and rolling stock, auto industry, farming and agriculture industry, and the list goes on.

Super CORR A is packaged in aerosol cans making application to component parts easy for engineering crews in difficult locations and conditions. Unpainted mild steel will not rust on exterior surfaces directly exposed to sea water environments for at least 6 months, protecting electrical connectors, switches, chains, drive shafts from corrosion while maintaining lubrication on moving surfaces.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

HISTORY

Super CORR A was originally developed for the U.S. Air Force to comply with military specifications and to prevent electrical and electronic components from systems failures caused by corrosion. It became the industry standard for avionic corrosion protection within MROs (maintenance, repair and operations) and OEMs (overhaul and original equipment manufacturers). It’s unique ability to displace water and provide a performance enhancing level of corrosion protection has led to it being used in many other applications and industries worldwide.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Latest News

Industrial solvent cleaners

Clarea® general purpose industrial solvent cleaners are safe for users and the environment

Clarea® non-chlorinated industrial solvent cleaners are compatible with all metals, composites and most plastics used to remove dirt, oil, grease, or other contaminants from surfaces without causing harm or leaving residue. They are used as immersion cleaners for component cleaning in manufacturing and engineering industries and as wipe cleaners for large surface areas prior to painting or powder coating. The environmental concerns and health hazards of the chlorinated solvents used as industrial degreasing agents has led to the formulation of this EnviroTech range of safer cleaning solvents.

What to consider when choosing suitable solvent cleaning products?

Solvents used for cleaning must be highly refined and leave no residues on drying. They need to be highly effective removing oils and soils without causing damage or corrosion of the parts or components being processed and leave minimal residues.

Cleaning specifications vary widely from very demanding automotive and aerospace applications to less demanding applications where critical cleaning is not needed such as pre-used parts or assemblies from the transportation, aerospace, or manufacturing equipment sectors. Heavily contaminated when removed from service these must be free of oils, soils, grease and dirt before disassembly prior to refurbishing and rebuilding. Much of this work will be manual and the considerations for the safety of operators, hand wiping or brush cleaning is paramount.

Clarea® products are aliphatic hydrocarbon based low odour degreasing solvents with specified flash points. They will remove oils, greases, hydraulic fluids cutting fluids and a wide variety of hydrocarbon based protective coatings. Clarea® solvents can be safely used with all metals and composites and most plastic and paint finishes.

Clarea® HC40 is low odour degreasing fast drying solvent with a flash point of 40°C. It is suitable for ultrasonic and dip systems and can be used with brush or in hand-wipe processes.

Clarea® HC462 is a degreasing solvent with a flash point over 60°C. It is suitable for hand-wipe applications when used externally.

EFFICIENT AND ECONOMICAL

- Versatile and cost-effective solutions for all your industrial cleaning

- Minimal odour and low toxicity for operators

- Multipurpose uses can reduce the inventory of cleaning fluids.

- Flexible uses – evaporation rates suitable for hand wipe, spray, or immersion tank cleaning

- Clarea HC40 for brush and hand wiping, air dries. Flash point 40°C

- Clarea HC62 for spray or immersion cleaning Flash point 62°C

- Contains no chlorine, other halogens or stabilisers

- Compatible with all metals and composites and most plastics

- Excellent pre-cleaner for paint or powder coatings

- Safe, reliable, environmentally friendly cleaning

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Solvent Degreasing and Metal Cleaning

Solvent Degreasing and Metal Cleaning –

Future proof Vapour Degreasing from EnviroTech Europe

Innovation driven by legislation

Vapour degreasing, with or with-out ultrasonics, is the oldest, simplest and most effective solvent degreasing and metal cleaning process used today. It has, until recently, been subject to little change since it was first invented in the early part of the last century. In the UK, Europe, United States and other advanced industrialized economies increasingly stringent legislation to control emissions of VOCs, Global Warming Compounds, Ozone Depleting Compounds, and those compounds associated with human health concerns has led to new formulations for precision cleaning solvents.

Cleaning systems have had to change too. With increased legislation concerning the regulation of health and environmental safety, uses of solvents have been targeted and alternatives are encouraged by the relevant authorities and law makers, often without serious consideration of unintended consequences. For example, water-based cleaning is the obvious alternative but this has many disadvantages compared to vapour degreasing as although the machines are simple and relatively cheap the processes require multiple tanks for immersion or spray processing or long programmed cycles in batch machines for cleaning, rinsing and drying. Water based processes are slow, energy intensive and occupy more floor space than vapour degreasing equivalent where only one tank with small footprint is needed delivering shorter process times and most importantly using minimal energy. Then there is the disposal concern as the used water cannot just be disposed of by pouring it down a drain.

The ideal cleaning process would be vapour degreasing and cleaning with water, but due to the physical characteristics of the vapour/steam and the inability to carry surfactants to remove the oil, grease and soils and the difficulty of rinsing and especially drying this will only ever be a dream.

Halogenated hydrocarbons are the solvents of choice for vapour degreasing and cleaning. The process is essentially simple. A tank with a sump to contain the solvent, heaters at the base and condensation coils around the top section to control the height of the vapour is all that is needed. When heated in the sump halogenated solvents produce, in most cases, a saturated vapour between 3 and 4 times heavier than air at a temperature greater than the ambient temperature of the parts to be cleaned. This allows the solvent vapour to condense on the surface of the parts. The condensate dissolves the contaminants such as oil, greases, flux, and soils returning the used solvent into the sump of the machine for recycling into vapour which continuously condenses onto the parts until they have achieved vapour temperature when, with no further condensation, the process is complete. Parts removed from the cleaning machines are very clean, warm and dry.

The most common halogenated solvents, in use for commercial purposes, are non-flammable so present no risk in this process. Perchloroethylene, used mainly for dry cleaning, methylene chloride previously used widely in paint strippers, 1,1,1- trichloroethane and trichloroethylene used for vapour degreasing were the original materials used based on chlorine chemistry. However continuing concern about the environmental impact and danger to operators by exposure to chlorine-based solvents, especially trichloroethylene, has led to a continuing search for safer alternatives, such as ProSolv 5408e, a trans-1,2-Dichloroethylene based solvent mixture that is non-flammable.

As with all legislation for chemical use regulation and restrictions drive development of associated processes and equipment. The most important developments in vapour degreasing cleaning machines to use solvents for vapour degreasing use two different approaches and raise difficult questions as to which is the best most economical and simplest in use.

The single tank hermetically sealed machines favoured by mainly German manufacturers uses a process tank to contain the solvent and a separate storage tank/vapour generator. Baskets with parts to be cleaned are loaded from the top and lowered into the process tank. A lid then closes over the tank and is hermetically sealed. Solvent is pumped into the process tank. Baskets are immersed in the solvent where agitation, ultrasonics or pumped liquid is circulated through the parts. When the immersion process is complete solvent is pumped to the storage tank and vapour fed to the process tank from a vapour generator for rinsing and drying. Condensing coils/panels controlling the vapour height are linked to coils located within the vapour zone which, when the cycle is complete, collapse the vapour. The process tank is emptied. The saturated air/solvent from the process tank is then recycled through carbon absorption units to remove traces of solvent from the air until the concentration is below 2 grams per cubic meter when the lid opens automatically for the basket of parts, clean and dry, to be removed and replaced with a further basket.

Variations within the hermetically sealed tank are possible using sprays of cold or hot condensed solvent, immersion with or without ultrasonics and revolving baskets to cover most of the problems experienced when processing machined and fabricated parts. Continuous external distillation of the contents of the vapour generator is also an option depending on contamination.

The alternative technology is much simpler and cheaper and less time consuming using well trained techniques. This is favoured by UK based manufacturers. The multilevel system shown in the diagram uses a standard vapour degreasing tank design with a sealed loading section above the process tank.

Work baskets are fed to the load section from a hoist or conveyor. The loading door is then pneumatically sealed to hermetically isolate the process. The sealing lid on the process tank is opened and the basket lowered into the cleaning tank which can be simple vapour degreasing with vapour generator below or an offset generator can be used with the lower section being filled with clean solvent for immersion cleaning with or without ultrasonics or power sprays. Revolving baskets can also be added to improve cleaning in blind or through holes or oil ways in castings and fabrications.

When the process is complete the basket rises to the freeboard area where the condensation coils are located, and parts are allowed to drain and dry. The tank seal opens to allow the basket into the load section while the lid closes again across the process tank. A fan is then activated which produces a negative vacuum in the load area. The loading door is then partially opened to allow a flow of air through the loading section which is exhausted to atmosphere or can be recycled through carbon absorption systems if no external exhaust is preferred. As baskets entering the loading space contain parts drained and dried only very small amounts of solvent are carried in the exhausted air which is monitored to ensure compliance with local legislation. When this is achieved the door opens fully for removal of basket. The loading section can be fitted with top or side sealed doors allowing baskets to flow through on conveyor systems or be loaded from hoists. No solvent enters the work area. Both processes will produce parts cleaned to the highest standards but the choice of which offers the best solution needs a little more consideration.

The single tank process is complicated with the need to move liquids in the machine. It is relatively slow as the carbon adsorption process needs to remove high levels of solvent from the recirculated airstream from the process tank. This is inefficient as adsorption rates for carbon fall rapidly with increasing saturation. Final levels of solvent in the tank when the lid opens will be dragged into the workshop and the area in which the operator is working. Long process cycles reduce throughput.

The simpler multilevel systems where movement of liquids is not required are more efficient and offer much faster process times. Cost of manufacture is also cheaper as no liquid movement is involved. The extracted loading section ensures no leakage of solvent into the work area which offers complete safety for operators and factory staff. The disadvantage of the multilevel machine is the height of the equipment compared to the single tank machine. This will often require the equipment be installed in a pit for easy access.

Both designs of process machines fully comply with the emission regulations of the UK, EU and U.S authorities. Which to choose will depend on many factors which should be discussed with both the equipment and solvent suppliers who have the experience to advise on which offers the best process for the application. Equipment and solvent must work together and it is advisable to ensure that the suppliers work closely together to offer a package with high levels of responsible care and product stewardship to ensure the best and safest installation.

The vapour cleaning process still gives the highest levels of economical cleaning with minimum energy usage, low footprint on the factory floor, safety for the operator, and high production rates with low solvent usage or environmental impact. With the new generation of sealed cleaning machines its future as the process of choice is assured.

Envirotech Europe supplies three distinct products that use this process and we are happy to advise you on the best solution to suit your needs. Please visit our website to find out more about ProSolv 5408e, ProSolv and EnSolv® CC-A.

Image of Solvac hermetically sealed equipment by kind permission of CC Hydrosonics Ltd.

FURTHER INFORMATION

Please visit our website www.envirotech-europe.com for information about other uses and applications for our vapour degreasing and cleaning products.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Electrical corrosion protection

Electrical corrosion protection – Prevent hydrogen sulphide corrosion in electrical and electronic equipment

Super CORR A is a proven and cost-effective way to prevent or inhibit corrosion from destroying electronics and electrical components. Adverse work environments where corrosive gases such as hydrogen sulphide are found, can cause severe corrosion and rapid deterioration of electronic components and equipment, including connectors and switches.

Lost productivity and revenue caused by plant and equipment downtime

Corrosion, in its many forms, costs both private and public sectors hundreds of billions of Euros a year to repair or replace electrical, electronics, or avionic components because of failures caused by corrosion. While all metals corrode, due to a number of different factors, there is no simple or single solution to the overall corrosion problem. However there are some very cost effective and proven ways to prevent corrosion and failures caused by corrosion and thereby reducing or eliminating associated costs and increasing safety which should be foremost in the mind set of any preventative maintenance programme manager.

Super CORR Awas specifically designed to lubricate and prevent corrosion in electrical fittings and connectors; electrical and avionic harness assemblies and connectors; electrical and electronic switches; close tolerance and dissimilar metal components; lighting connectors and sockets. A unique non-flammable “self-healing” ultra-thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack, is not a wax or oil-based product and is formulated without sulphates, chlorides or halogens.

Super CORR A inhibits corrosion caused by exposure to both fresh and salt water moisture as well as the corrosive vapours from Sulphur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulphide (H2S), Ammonia (NH3), and Chlorine (CL12) based gases found in waste water and sewer treatment plants, pulp and paper mills and plants, chemical and petroleum plants, maritime industry, aircraft/airline industry, military equipment including ships, aircraft, and rolling stock, auto industry, farming and agriculture industry, and the list goes on.

Super CORR A extends the working life of electrical components and systems and other critical items by preventing the deterioration and/or failure caused by corrosion and can significantly reduce downtime, operating and maintenance costs as well as enhance safety. An ultra-thin film, water displacing lubricant and corrosion inhibiting compound Super CORR A has undergone extensive testing by Battelle Labs as well as the U.S. Air Force and meets MIL-DTL-87177B (revised MIL-L-87177A) specification. SuperCORR-A is used by NATO (NATO NSN 8030-99-226-6966) to protect avionic, electrical, electronics, electrical switches and connectors and components from corrosion in both the military and civilian aircraft. Savings for the U.S. government alone is estimated to be in excess of $50 million per year.

Super CORR Aprovides a superior lubrication coefficient and protects components against moisture, wear, general and fretting corrosion, surface static electricity, corona, and other electromigration problems. The super thin non-flammable lubricant film is only 7 microns (0.00028 inch) thick and is formulated to meet the RoHS directive. It is unexcelled in preventing deterioration and contamination on all surfaces of electronic equipment.

The question for you is: What is the cost of NOT using Super CORR A in your preventative maintenance programme?

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

Share this page:

ProSolv®5408e vapour degreasing solvent cleaner for flushing refrigeration pipeline systems

Vapour degreasing solvent cleaner for flushing refrigeration pipeline systems

Concerns connected with the challenging environmental profile of traditional refrigerant gases have led to changes in legislation which are a driving factor in phase-outs and bans on the use of some gases to remove the older materials typically with high ozone depletion (ODP) and global warming potential (GWP). Systems can be replaced or refurbished with new models using compressors able to use more sustainable and acceptable gases. The evolving trend to newer refrigerants continues as the chemistries develop. The refrigerant R-22, which itself was an improvement over earlier refrigerants, is phased out and replaced with R-410a and other alternatives based on HFOs are being marketed.

Retrofitting of current refrigeration systems to accommodate the new developments is not straightforward as most refrigerant gases are not cross-compatible, so the necessity to completely remove all traces of the older versions from the system, including refrigerant lines is essential.

Of course, where possible it’s best simply to replace existing lines with new ones. However, it’s not always possible to do this cost-effectively, especially when the old piping runs under floors or through walls. In such cases thoroughly flushing existing pipework is especially important because even tiny traces of impurities left in the lines can damage new equipment and lead to compressor failure.

THE PERFECT SOLVENT FOR FLUSH CLEANING REFRIGERATION PIPEWORK

Your first step to proper pipework flushing is to select the right solvent. The solvent you choose must be highly effective at dissolving oil grease and other contaminants, to ensure that all residue is removed from the pipes and must be sustainable, environmentally friendly and comply with current legislation.

ProSolv 5408e is the ideal solution to this problem with a profile of properties and advantages making it perfect as your solvent of choice for refrigerant pipeline flushing.

• No flash point Non flammable liquid.

• High specific gravity gives a high soil suspension loading.

• High solvency strength with a KB value of 98.

• Powerful cleaning agent that can flush lines fast, dissolving oil and grease releasing soils from the inner surfaces of pipelines and fittings

• Volatile for fast evaporation. Removing ALL solvent from the pipework after flushing is vital, very volatile so evaporates fast.

• Environmentally responsible. ProSolv 5408e is sustainable and kind to the environment with very low global warming potential, zero ozone depleting potential (ODP).

• Safe for operators when user conditions are followed.

• Economical as it is easily distilled for reuse. No testing or stabilisation required.

PROCEDURE FOR FLUSH CLEANING REFRIGERANT PIPELINES WITH ProSolv®5408e

Of course, simply replacing old piping is the only way to be 100 percent sure that your lines are clean. But in retrofit situations where complete replacement is not possible, flushing the lines with ProSolv 5408e solvent is the best alternative solution for the protection and long working life of your refrigeration system upgrade.

1 – Remove any obstacles. Any equipment and components such as valve, filters and expansion valves that might obstruct the line should be removed prior to the purge.

2 – Pre-flush. This will dislodge any loose debris from the sides of the lines enabling more effective use of the solvent, oil free air or nitrogen at 120 psi is recommended. It’s also good practice to oscillate the pressure to encourage dislodging of debris.

3 – Preparing the pipework. Reducing the length of piping can be more effective due to the pressure loss in long lengths. Section the operation into 15 metre lengths by cutting pipes where necessary. One end of the pipe must be fitted with a connector for the pipe to the nitrogen supply while the exit needs a restrictor valve to allow variable pressures to shock loose particles from internal walls.

IMPORTANT – Flushing with solvent. Refer to ProSolv 5408e Safety Data Sheets for advice on operator protection using solvents.

4 – Safe working. Full PPE with suitable eye protection goggles and gloves must be worn. Solvent fumes are heavier than air and exposure levels can easily be reached working in pits or enclosed spaces. Always institute a ‘buddy system’ and use air fed face masks with attached line.

5 – Delivering solvent. Use a drum pump electric or hand operated with a flexible tube connection for delivering the solvent to the open end of the pipe or tubing to flush the internal surfaces. Using a fresh drum of ProSolv®5408e connect drum pump and the delivery tube to the end of pipe/tube to be cleaned using a pre-fitted screwed or compression fitting.

6 – Drainage and Testing. The drainage end of the pipe or tube should be fitted with a flexible tube into a tank or drain sump allowing samples to be taken in a glass bottle or tube at regular intervals to be sure when no particles or soils are being expelled. The colour of the solvent will change as oil and soluble contaminants are removed and flushing must continue until the flow is totally clear and water white.

7 – Post-flush. ProSolv 5408e solvent is volatile so will dry completely using an oil free airline or nitrogen supply connected to the end of the cleaned pipe/tubing.

8 – A wipe of the pipe/tubing surface at the inlet and outlet using solvent saturated lint free cloth completes the cleaning. If not connected immediately to other parts of the system enclose both ends of cleaned item to prevent recontamination.

Used ProSolv 5408e should not be reused for flushing but can be recovered for reuse by a simple distillation process. Removal from site should use licensed disposal companies.

Further information:

For more information and advice please contact us by telephone on +44 (0) 20 8281 6370 or use our contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

ProSolv 5408e is not just flushing refrigeration pipeline systems,

https://www.vapour-degreasing.com/prosolv5408e/ for information about other applications.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

VOC Exposure Monitoring

Exposure monitoring – Reassurance that your equipment is functioning within agreed safety margins.

Envirotech Europe has always considered it has a duty of care to its loyal and new customers and VOC monitoring is an issue we take seriously. As an employer, it’s your job to ensure that you correctly control the personal exposure levels of staff to a wide range of chemicals, substances and even radiation.

The Control of Substances Hazardous to Health (COSHH) Regulations 2002 places a duty on the employers to undertake assessments to evaluate the risks to health when using hazardous substances in the workplace.

We have portable test equipment that logs the Volatile Organic Compound (VOC’s) content in the air from various strategic positions around your degreasing equipment, including the operator position.

This kit is based on very accurate photoionization detectors (PID) designed to constantly log the quality of the atmosphere and keep your workers safe.

We would generally test for a full shift, analyse the data and report back within a few weeks with any suggestions for improvement.

Reassurance that your equipment is functioning within agreed safety margins and that any emissions into the working environment surrounding the machine are within prescribed limits.

A check that the ProSolv 5408e, EnSolv® CC-A or ProSolv system is operating economically and with the minimum of wastage. We can still carry out the testing for you even if you are using an alternative solvent.

FURTHER INFORMATION

For more information please contact: sales@envirotech-europe.com

Please visit www.envirotech-europe.com for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

Share this page:

Vapour degreasing solvent for precision parts cleaning

EnSolv® CC-A vapour degreasing solvent for precision parts cleaning

The EnSolv® CC-A formulation for precision parts cleaning responds to the need for high performance vapour degreasing solvents for critical cleaning in general engineering, aerospace, medical optical and electrical industries.

EnSolv® CC-A removes cutting oils, lubricants, lapping compounds grinding pastes and water based cutting oils or fluids. This complex synergistic blend utilises environmentally compliant solvents combined with selected surfactants to remove oils and lubricants to the highest standards for critical cleaning applications and releases and suspends inorganic solids and soils such as fingerprints, polishing compounds and grinding paste from finely finished and highly polished surfaces such as stainless steel and plated parts, optical lenses and components for medical appliances.

IMPROVES PRODUCTIVITY AND OPERATING ENVIRONMENT

Suitable for processing temperature sensitive components as well as the conventional engineering substrates. The very low surface tension cleans through holes on castings and penetrates between overlapping metal spot welds eliminating oil leaching in paint and powder coatings during oven curing.

Easy handling – Cleaned components are dry and comfortable to handle immediately at the ideal temperature for painting or powder coating. No time lost waiting for parts to cool which allows immediate quality control testing or assembly of machined parts due to minimal dimensional changes.

Cleaning cycles reduced, productivity improved with output doubled compared to conventional solvents.

Minimises flash rusting on mild steel cleaned components due to the advanced stabiliser/inhibitor package compared to alternative formulations.

Compatible with mixed metal components. No staining of yellow metals, bronze, copper, aluminium.

Reduced maintenance – unique additive suspends contaminants in boiling solvent sump preventing tar formation and continuously cleans heating surfaces. Longer periods between cleanouts reduces labour costs and solvent losses.

Talk to us about whether EnSolv® CC-A is the best choice for your application. Advice, literature, changeover instructions are all available to make the change quickly, easily and at no extra cost of usage.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/ensolvcc-a for information about other uses and applications.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

Share this page:

Related Posts

Corrosion protection – Reduce fretting corrosion

Corrosion protection – SuperCORR A helps to reduce fretting corrosion on gas turbine connectors.

LP Gas Turbines are used throughout the world by extraction industries and manufacturing plants in remote and hostile locations for essential power production. Dusty and wet environments in deserts, mines, grinding mills, pulp and paper mills and on land or sea drilling rigs for gas and oil production. Turbines powering aircraft services while stationary connect and disconnect many times a day in extreme conditions. These applications and locations test connector sealing continuously allowing dust or water to penetrate. This with the flexing of the connecting cables allows sufficient movement between the metal surfaces of the connecting pins to produce fretting corrosion which reduces, interrupts or produces failures in supply. Regular maintenance of electrical connectors is essential to be certain of uninterrupted supply.

RUB TEST RESULTS

Super CORR A is an aerosol lubricant containing corrosion preventive compounds.

A manufacturer of connectors tested Super CORR A to see what the “life” of the lubricant was in a “rub test”. The typical test is 20,000 cycles, i.e. unplug, plug in is one cycle. The test results demonstrated that after 20,000 cycles there were no failures. It was decided to take it one more step and run the same tests for 200,000 cycles. The results again showed no indications of galling or scoring on the connectors at all. The connector looked and tested as good as new. This test was run under clean conditions in a laboratory but demonstrates the effectiveness Super CORR A.

As it meets Mil MIL-DTL-87177B (revised MIL-L-87177A) specifications it is used by the U.S. Air Force to protect the intricate workings of the F-16 and F-15 fighter jets and by the U.S. Navy on the P 3 Orion electronic surveillance aircraft. Savings for the U.S. government is estimated at $50 million per year. Commercial Aviation aircraft manufacturers recommend it for avionics and electrical switches and connectors and close mechanical application, especially where flights are in salt fog or high humidity.

Containing extremely long-lasting, proprietary anti-corrosive inhibitors Super CORR A provides a superior lubrication coefficient and protects components against moisture, wear, general and fretting corrosion, surface static electricity, corona, and other electromigration problems. The super thin non-flammable lubricant film is only 7 microns (0.007mm) thick and is formulated without sulphates, chlorides or halogens to meet the RoHS directive. It is unexcelled in preventing deterioration and contamination on all surfaces of electronic equipment.

Very fast drying, environmentally acceptable solvents are used as carriers and propellants which will not affect most plastics, substrates, metals or other materials used in connector manufacture. The aerosols are supplied with probes which allow access to pins and connector tubes where the low surface tension repels water, dirt dust and metal particles from blind holes and surfaces to produce thoroughly clean holes and surfaces before a second application applies the lubricant film. Reconnection to the supply with cleaned sections of the connector ensures reliable operation even in the most testing of environments. One can of Super CORR A allows this essential task to be carried out in any conditions quickly, easily and securely.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for for information about other uses and applications for Super CORR A.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

Share this page:

Methylene chloride based vapour degreasing solvent with a unique blend of surfactants giving it superior cleaning quality

EnSolv® CC-A is a methylene chloride based vapour degreasing solvent with a unique blend of surfactants giving it superior cleaning quality

EnSolv® CC-A responds to the need for high performance vapour degreasing solvents for critical cleaning in general engineering, aerospace, medical optical and electrical industries. It builds on 30 years of experience supplying the EnSolv® range of powerful and reliable vapour degreasing solvents to industries worldwide

EnSolv® CC-A removes cutting oils, lubricants, lapping compounds grinding pastes and water based cutting oils or fluids. This complex synergistic blend utilises environmentally compliant solvents combined with selected surfactants to remove oils and lubricants to the highest standards for critical cleaning applications and releases and suspends inorganic solids and soils such as fingerprints, polishing compounds and grinding paste from finely finished and highly polished surfaces such as stainless steel and plated parts, optical lenses and components for medical appliances.

SAFE FOR USERS AND THE ENVIRONMENT

Environmentally friendly cleaning all the constituents of EnSolv® CC-A are environment friendly and compliant with REACH. This proprietary blend has no global warming potential (GWP) no ozone depletion potential (ODP) does not produce ozone at ground level and is biodegradable. EnSolv® CC-A addresses many of the problems faced by the engineering industries in meeting environmental legislation.

Easily biodegradable all the components of the EnSolv® CC-A formulation are widely used in industry but only trace elements have been detected in atmosphere and they are not detectable in rivers, oceans or ground water. This is attributed to its high volatility and biodegradability by naturally occurring organisms. Released into the atmosphere it is photochemically degraded reacting with naturally occurring hydroxyl radicals producing only carbon dioxide and hydrogen chloride simple chemicals already present in the environment.

No depletion of the ozone layer and no global warming. EnSolv® CC-A has an atmospheric lifetime of only 6 months and does not accumulate in the atmosphere so is not transported into the ozone layer. The most urgent challenge for the future is reduction of gases which produce global warming. The solvents and any breakdown products of this formulation do not produce greenhouse gases and the reduced energy needs of vapour degreasing with EnSolv® CC-A lower the power station production of CO2 for equivalent work throughput.

No ground level ozone production – authorities are becoming increasingly concerned at ground level pollution causing increased asthma and bronchial diseases much of it due to photochemical production of Ozone affecting children and adults. EnSolv® CC-A has a minimal impact on ozone formation with an extremely low photochemical ozone creation potential (POCP).

Reduced solvent emissions (VOCs). Improving air quality is a high priority for the European Union and governments worldwide with the elimination of VOCs as a high priority. The use of EnSolv® CC-A with its excellent environmental profile assists the engineering industry to meet increasingly severe environmental legislation on solvent emissions allowing continued use of vapour degreasing with all the production benefits it offers.

PRODUCT BENEFITS

Designed for vapour degreasing

Removes oil, grease and soils fast

Simple drop-in replacement for n-propyl bromide and trichloroethylene

Low surface tension

Reduced costs

Compatible with all metals

User friendly

Increased production

Faster cleaning cycles

Components easily handled after cleaning

Safe for the environment

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/ensolvcc-a for information about other uses and applications.

Visit www.envirotech-europe.com/applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

Share this page:

Related Posts